Automatic compensation controller for fluid

An automatic compensation and control device technology, applied in the direction of fluid flow, mechanical equipment, etc., can solve the problems of increasing the cost of the valve body system, maintaining or increasing the output flow, and the valve core cannot be automatically adjusted, and achieves good response, sensitive characteristics and structure. Simple, Adjustable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in combination with specific embodiments.

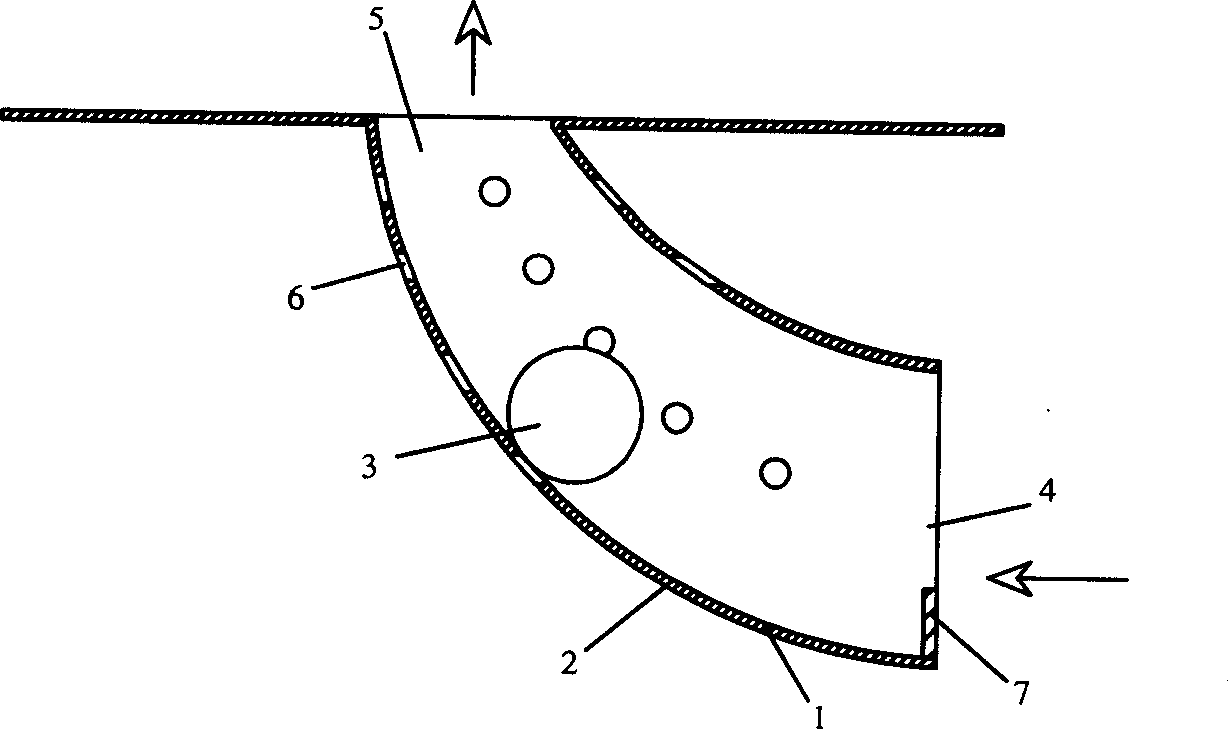

[0033] Such as figure 1 Shown is a schematic structural diagram of an embodiment of the present invention.

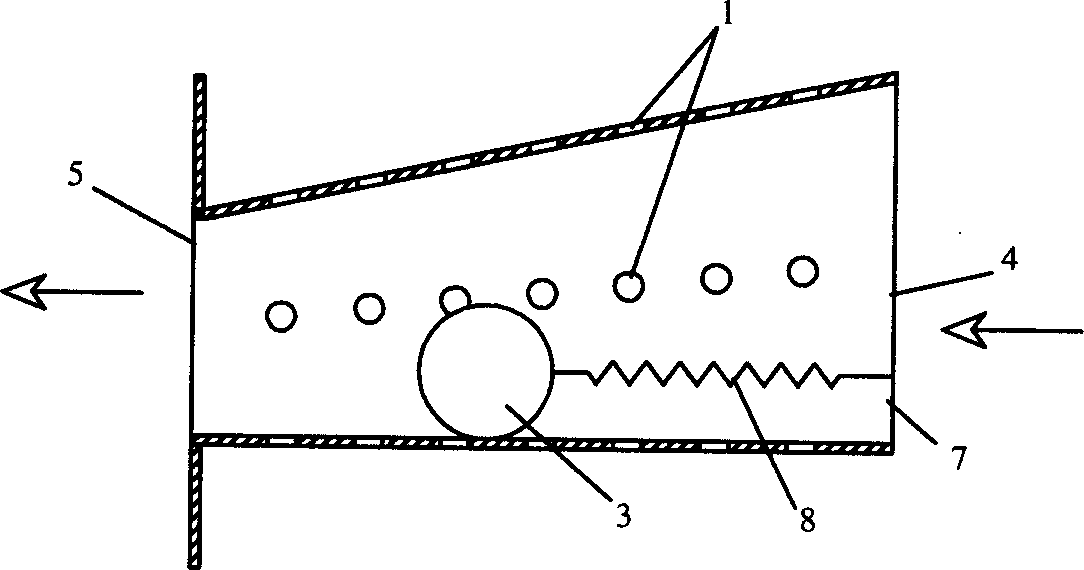

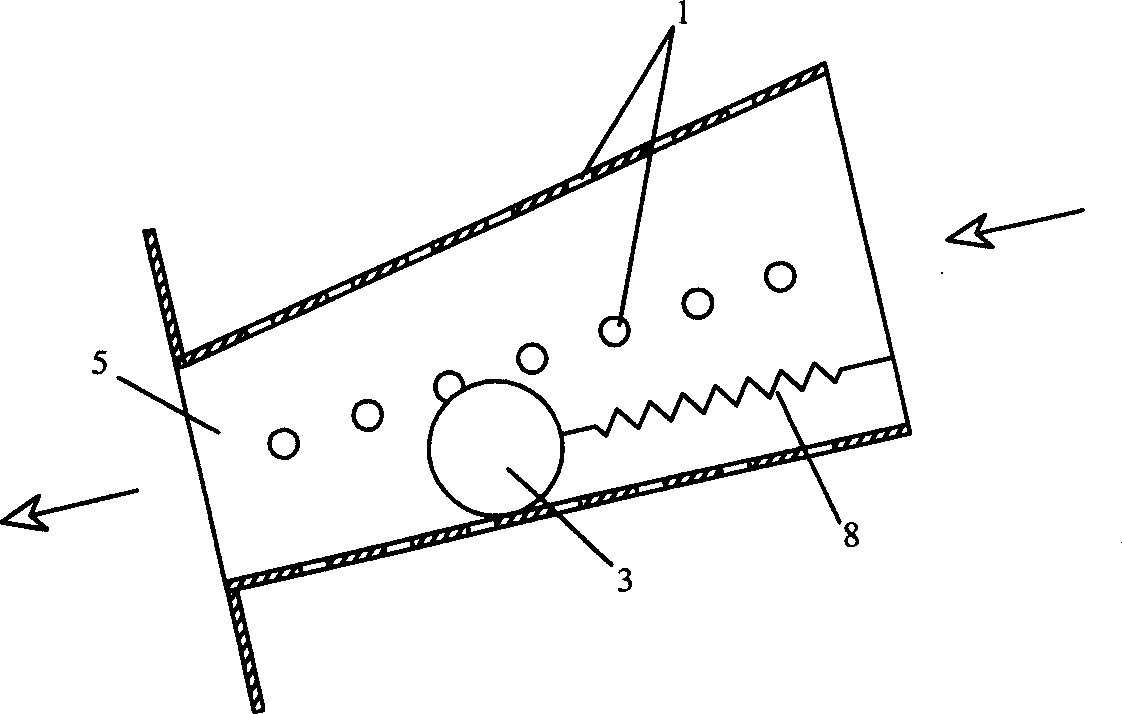

[0034] The flow channel 1 is a trumpet-shaped elbow structure, one end of which is the inlet 4, and the other end is the outlet 5. Adjusting holes 6 are uniformly arranged around the wall of the flow channel 1, and rollers 3 are arranged in the inner cavity of the flow channel 1. The roller 3 can roll freely along the inner cavity wall of the flow channel 1, and a baffle 7 is provided at the mouth of the inlet 4 to prevent the roller 3 from rolling down from the flow channel 1.

[0035] First of all, since the flow channel 1 is a trumpet-shaped elbow structure with a large inlet end and a small outlet end, when the fluid is passed through the flow channel 1, the roller 3 is in a certain equilibrium position, and its own gravity and the force of the fluid acting on i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com