Method for preparing isophorone from acetone

A technology of isophorone and acetone, which is applied in the field of preparing isophorone from acetone, can solve the problems of complex process and long catalyst preparation cycle, and achieve the effect of simple preparation process and good reaction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

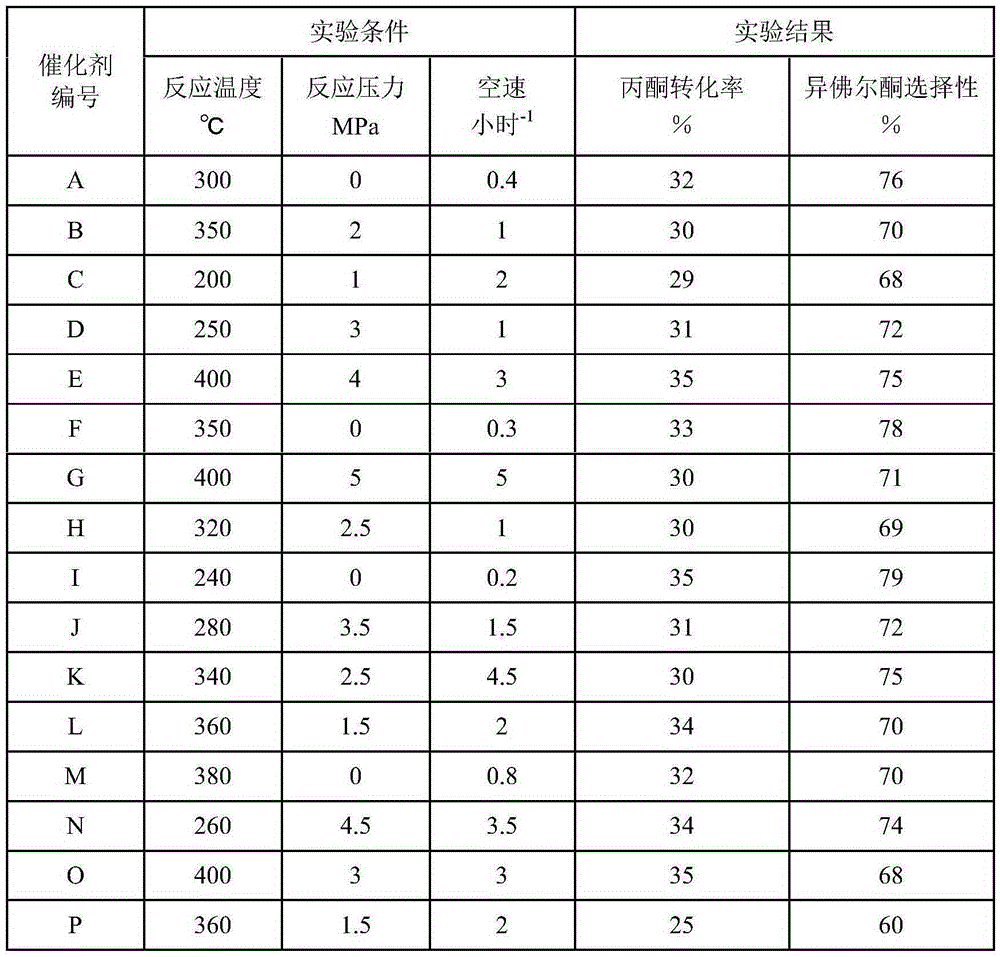

[0026] Weigh 200 grams of ZSM-5, 100 grams of magnesium oxide, and 10 grams of safflower powder, add them to the kneader and knead, knead for 10 minutes, slowly add 200 grams of 3% nitric acid solution, continue kneading for 30 minutes, and install the screw extruder after the kneading is completed Extruded, then aged at room temperature for 15 hours, dried at 100°C for 10 hours, and finally calcined at 600°C for 8 hours to obtain catalyst A. The catalyst performance evaluation test was carried out on a fixed-bed tubular reactor (Ф25×500 mm stainless steel), with a catalyst loading of 10 ml. The analysis of the reaction product was carried out by Agilent 6820, HP-1 column. The experimental conditions and reaction results are shown in Table 1.

Embodiment 2

[0028] Weigh 300 grams of ZSM-11, 50 grams of magnesium oxide, and 10 grams of safflower powder, add them to the kneader and knead them. After kneading for 15 minutes, slowly add 250 grams of 3% nitric acid solution, and continue kneading for 40 minutes. After the kneading is completed, install the screw extruder Extruded, then aged at room temperature for 10 hours, dried at 120°C for 6 hours, and finally calcined at 450°C for 16 hours to obtain Catalyst B. The catalyst performance evaluation test was carried out on a fixed-bed tubular reactor (Ф25×500 mm stainless steel), with a catalyst loading of 10 ml. The analysis of the reaction product was carried out by Agilent 6820, HP-1 column. The experimental conditions and reaction results are shown in Table 1.

Embodiment 3

[0030] Weigh 250 grams of ZSM-12, 180 grams of magnesium hydroxide, and 12 grams of asparagus powder into the kneader and knead. After kneading for 5 minutes, slowly add 300 grams of 5% acetic acid solution, and continue kneading for 20 minutes. After the kneading is completed, set the screw to extrude Extruded by machine, then aged at room temperature for 20 hours, dried at 90°C for 8 hours, and finally calcined at 500°C for 4 hours to obtain catalyst C. The catalyst performance evaluation test was carried out on a fixed-bed tubular reactor (Ф25×500 mm stainless steel), with a catalyst loading of 10 ml. The analysis of the reaction product was carried out by Agilent 6820, HP-1 column. The experimental conditions and reaction results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com