Intelligent secure cut-off mechanism assembly

A safety cut-off and assembly technology, applied in safety valves, mechanical equipment, engine components, etc., can solve problems that affect the normal life and production of users, do not have remote signaling functions, and cannot arrive immediately, etc., to achieve pressure difference reduction, The effect of increasing the membrane cavity and improving the control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] specific implementation plan

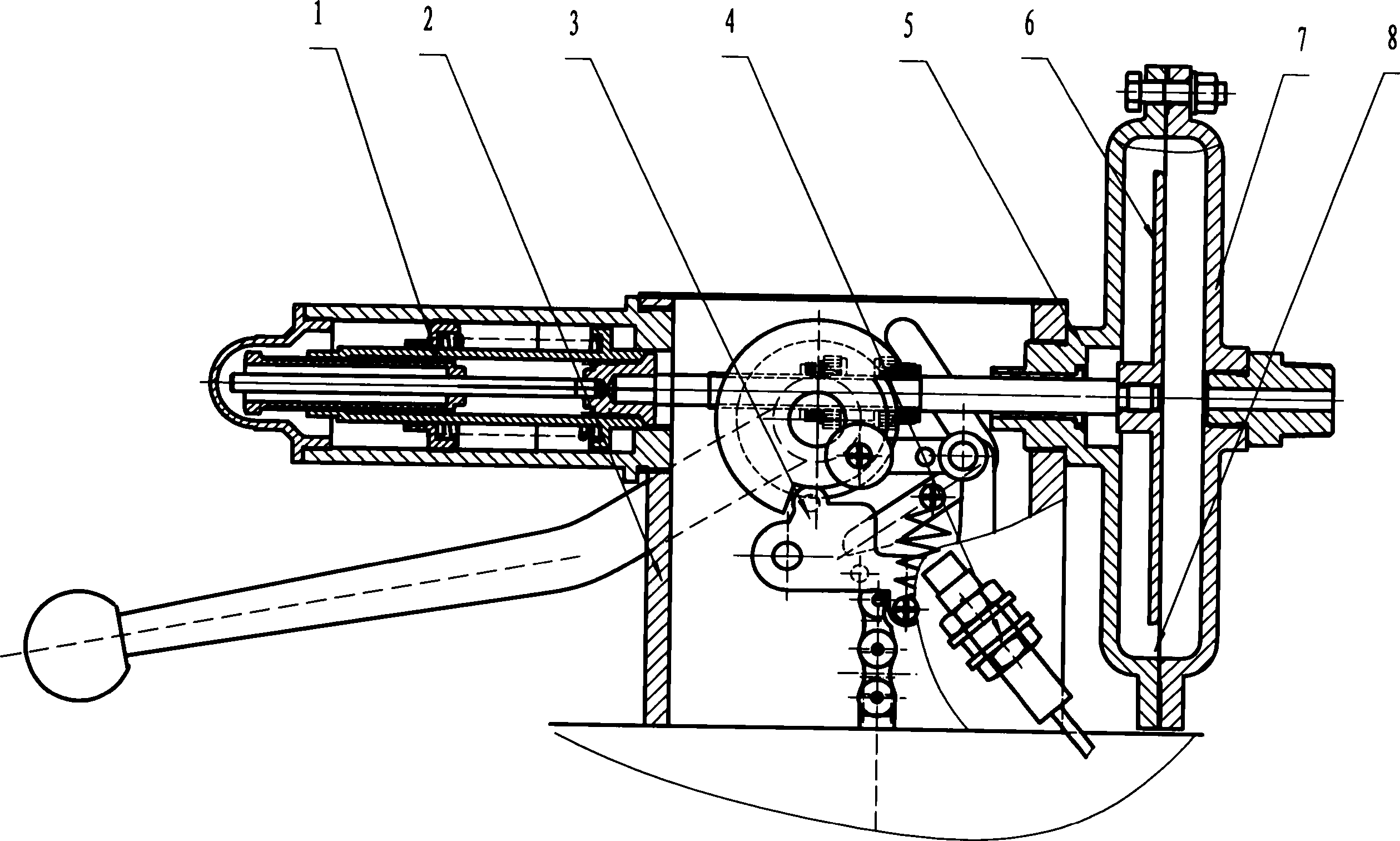

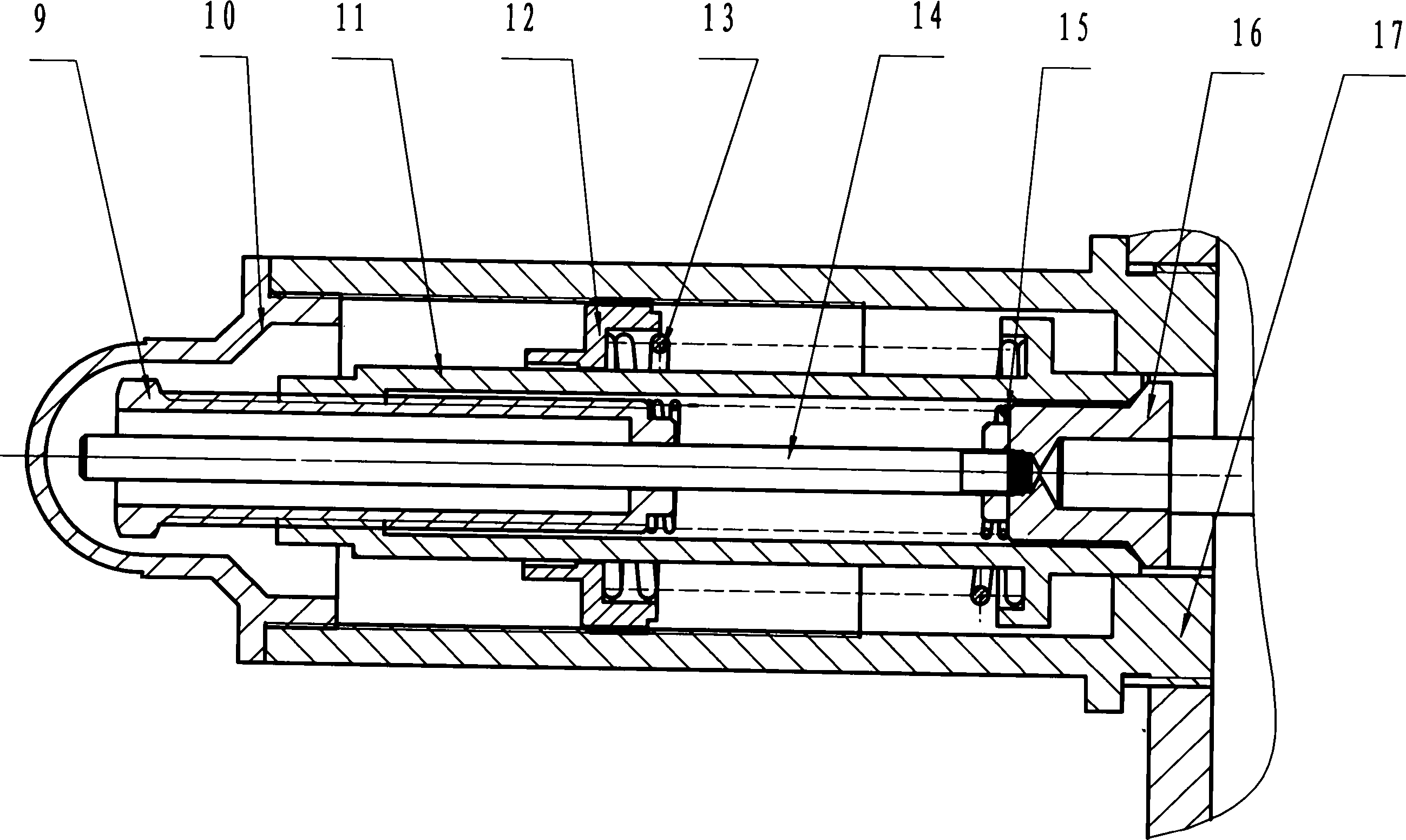

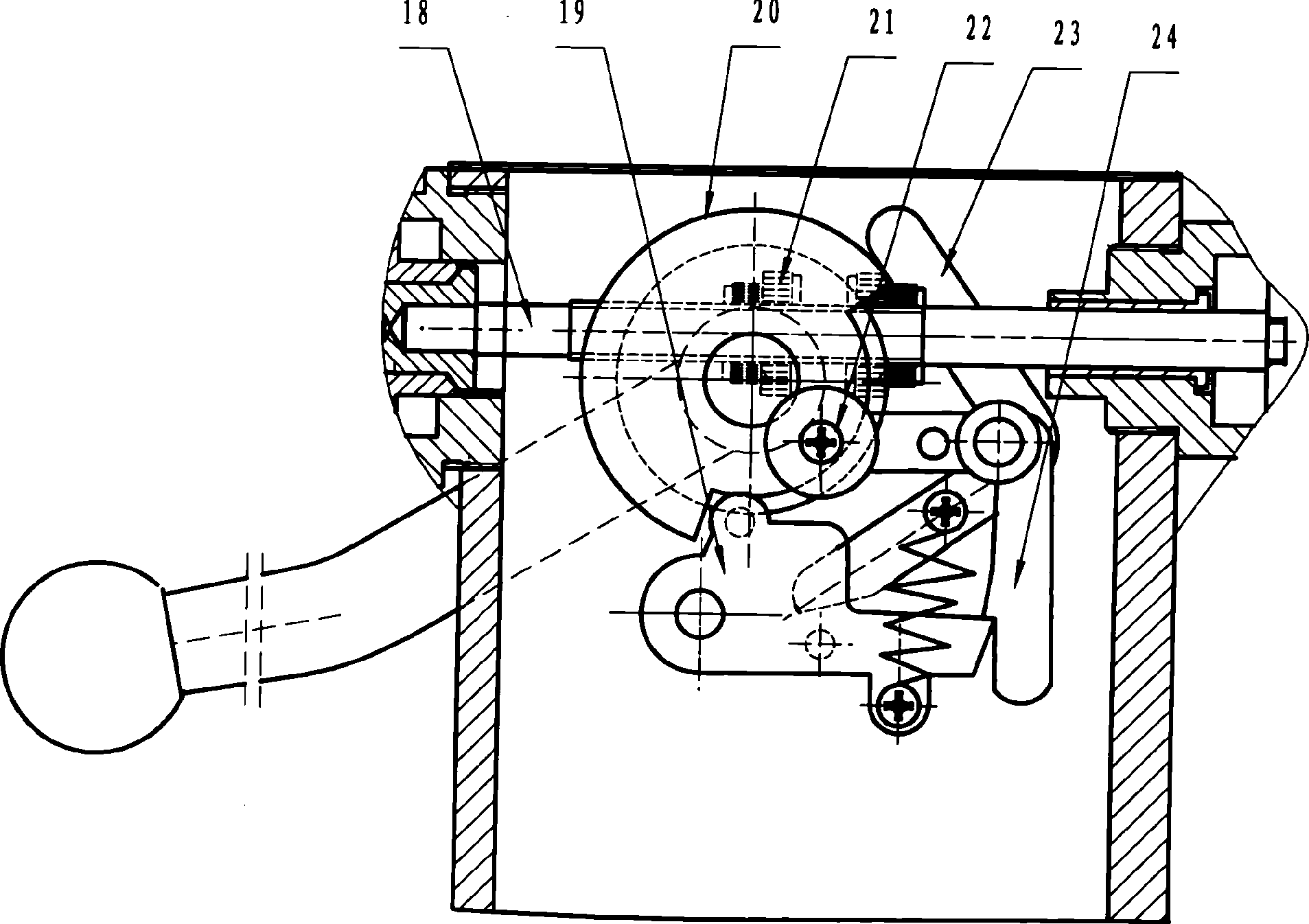

[0018] The intelligent safety cut-off mechanism assembly includes a membrane chamber assembly, a lever transmission assembly, a command valve body (2) and an adjustment assembly (1). The membrane cavity assembly is screwed on the command valve body (2) through threads, the lever assembly (3) is connected with the command valve body (2) through various small shafts, and the adjustment assembly (1) is screwed on the command valve body (2) through threads ), the movement direction of the adjustment assembly (1) is parallel to the flow direction of the cut-off valve. The membrane cavity assembly is composed of the upper membrane body (5), the lower membrane body (7), the tray (6), and the membrane (8), and the upper membrane body (5), the lower membrane body (7), and the membrane (8) are connected by bolts to form a Membrane cavity, cavity diameter 185-190 mm. The film is made of nitrile rubber with no skeleton and a Shore hardness of 40-45A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com