Lathe controller

A technology of control devices and lathes, which is applied to feeding devices, manufacturing tools, metal processing machinery parts, etc., can solve the problems of long training time for workers, long manual operation process, and lack of human resources for senior technicians, so as to save time and efficiency. The effect of improving accuracy and productivity

Inactive Publication Date: 2007-01-03

SHANGHAI YANAN HIGH SCHOOL

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In the current industrial production process, the production and processing of parts are mostly done by workers through manual techniques, and the training time of workers is relatively long

Moreover, the manual operation process is relatively long, which is too wasteful of manpower, and it cannot guarantee the accuracy of the entire operation process.

On the other hand, in the current market, the human resources of technicians, especially senior technicians, are extremely scarce. In addition, under the mode of "one person, one machine", the production efficiency is relatively low, which is in line with the growing demand for production technology parts in the contemporary era. In stark contrast

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

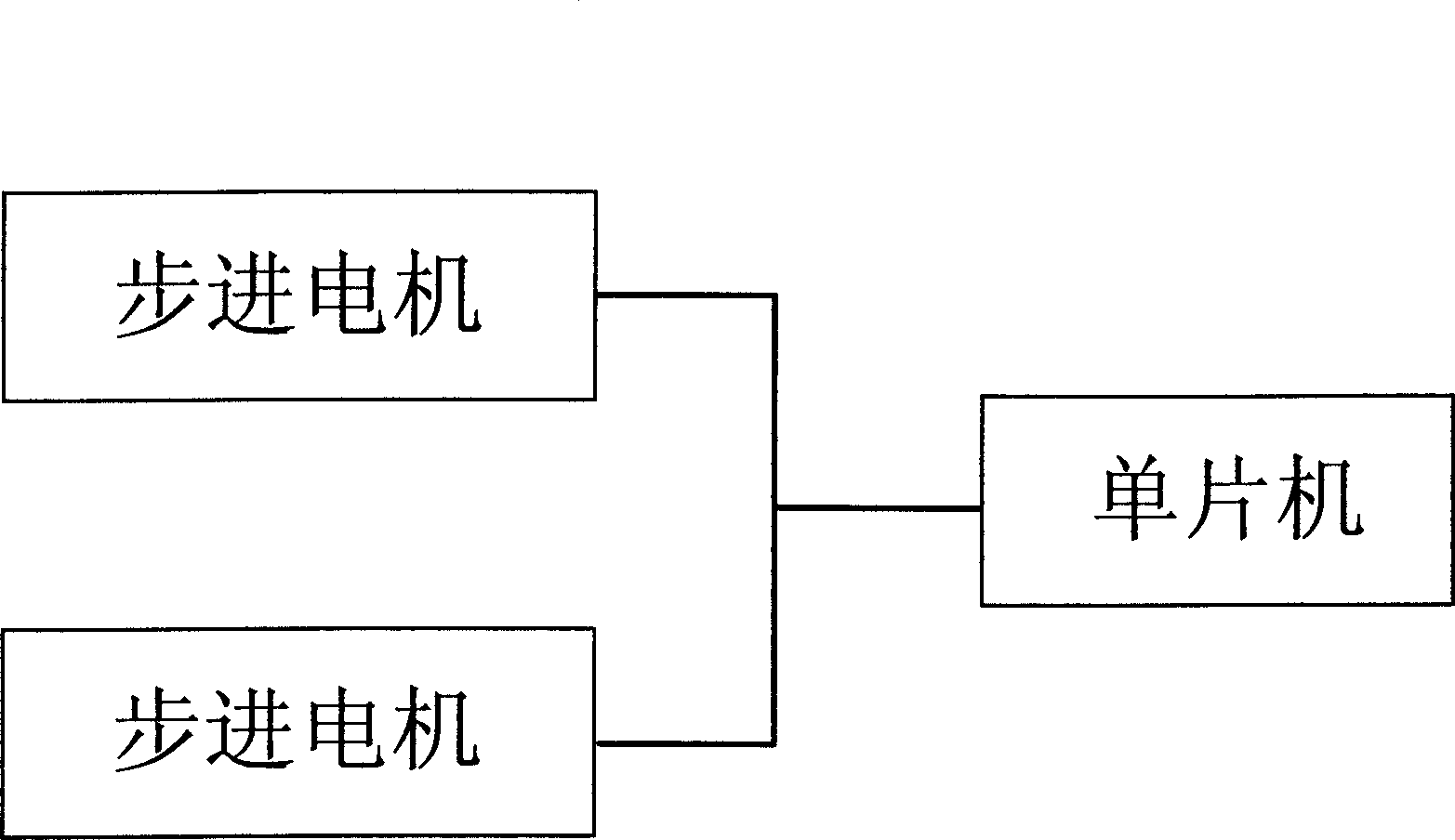

[0010] Depend on figure 1 The control device of a lathe shown includes two stepper motors and a single-chip microcomputer with an input keyboard. The output interface is respectively connected with two stepper motors.

[0011] The single-chip microcomputer is equipped with a PIC chip with the function of reading and writing programs.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The lathe controller includes two step motors and one monolithic computer with keyboard, and features these two step motors mounted separately onto the rocking handle shaft of the cross tool carriage and the longitudinal tool carriage, and the output interface of the monolithic computer connected to these two step motors. The monolithic computer is provided with PIC chip with program reading / writing function. By means of the said technological scheme, the present invention can make manual rocking handle lathe become automatic lathe with raised machining precision and efficiency.

Description

technical field [0001] The invention relates to a lathe component, in particular to a lathe control device. Background technique [0002] In the current industrial production process, the production and processing of parts are mostly done by workers through manual techniques, and the training time for workers is relatively long. Moreover, the manual operation process is relatively long, which is too wasteful of manpower, and the accuracy of the entire operation process cannot be guaranteed. On the other hand, in the current market, the human resources of technicians, especially senior technicians, are extremely scarce. In addition, under the mode of "one person, one machine", the production efficiency is relatively low, which is in line with the growing demand for production technology parts in the contemporary era. In stark contrast. Therefore, there is an urgent need for the emergence of a lathe with a higher degree of automation improved on the original lathe, so as to ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23Q5/34

Inventor 翁才昊徐靖宋婷婷高国强

Owner SHANGHAI YANAN HIGH SCHOOL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com