Door structure for rotary drum machine

A technology for drum washing machines and door frames, which can be applied to other washing machines, washing devices, textiles and papermaking, etc. It can solve problems such as peeling off of decorative tapes, decreased adhesion of double-sided adhesive tape, and aging of adhesive tapes, and achieves a beautiful appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

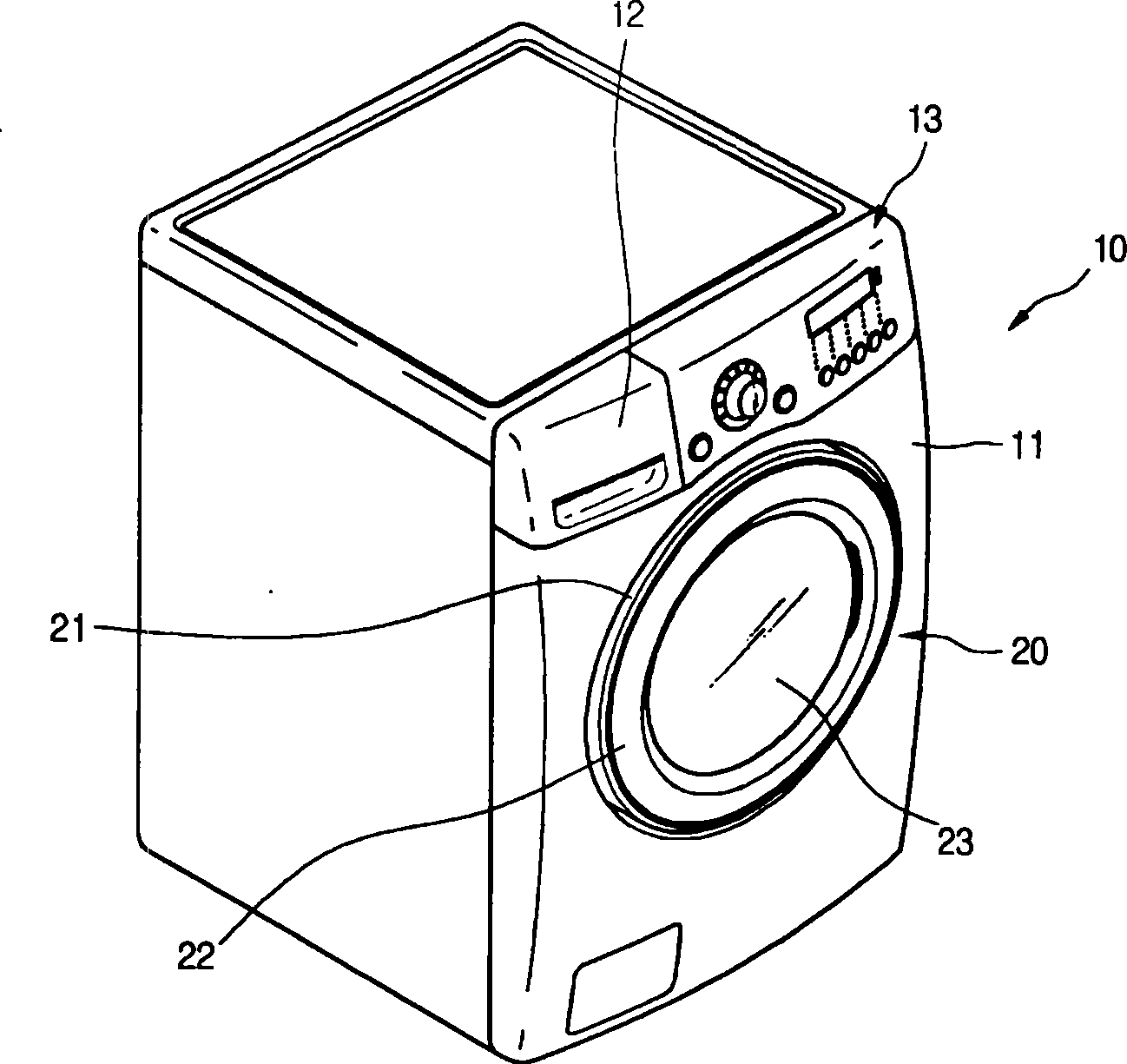

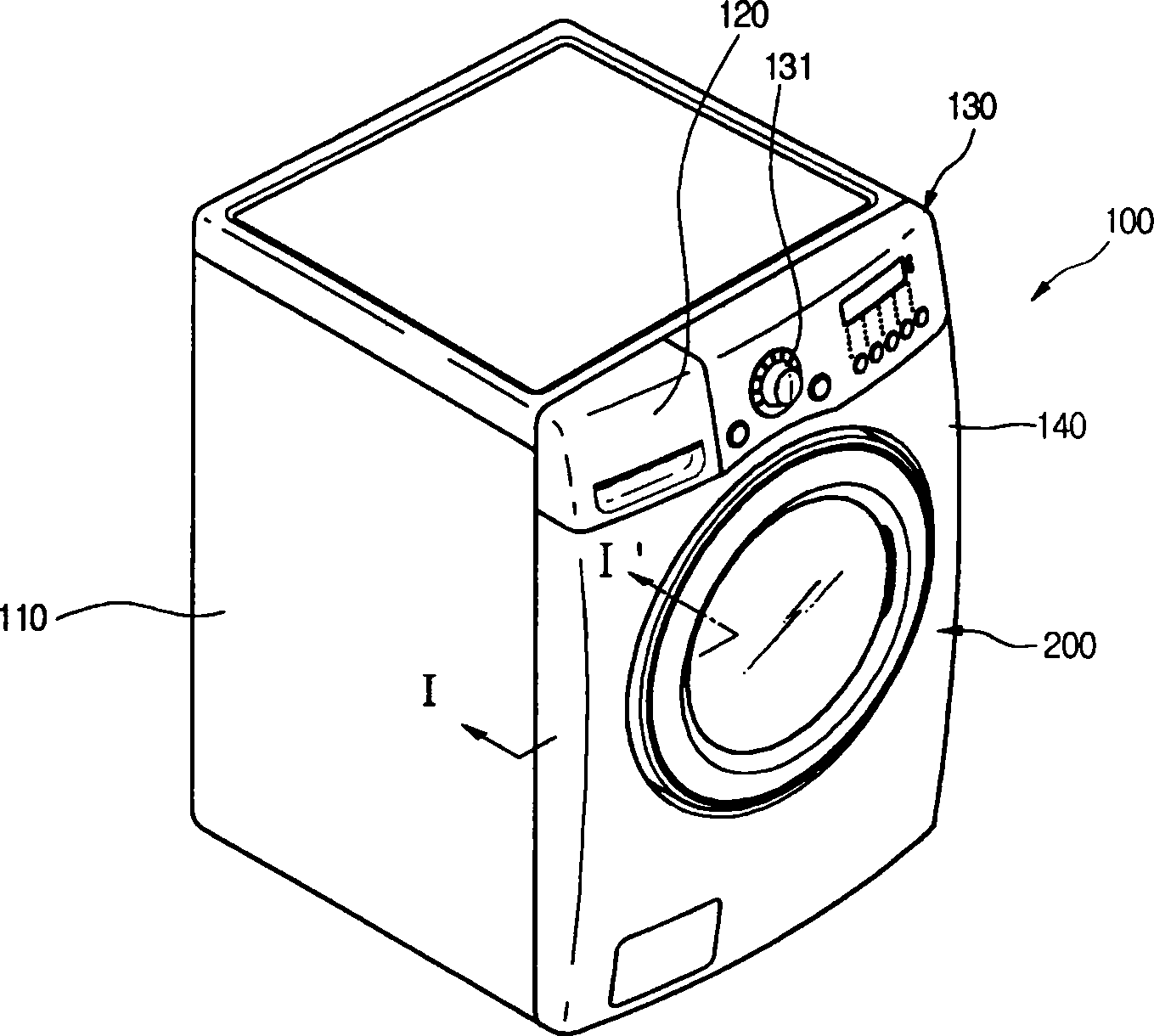

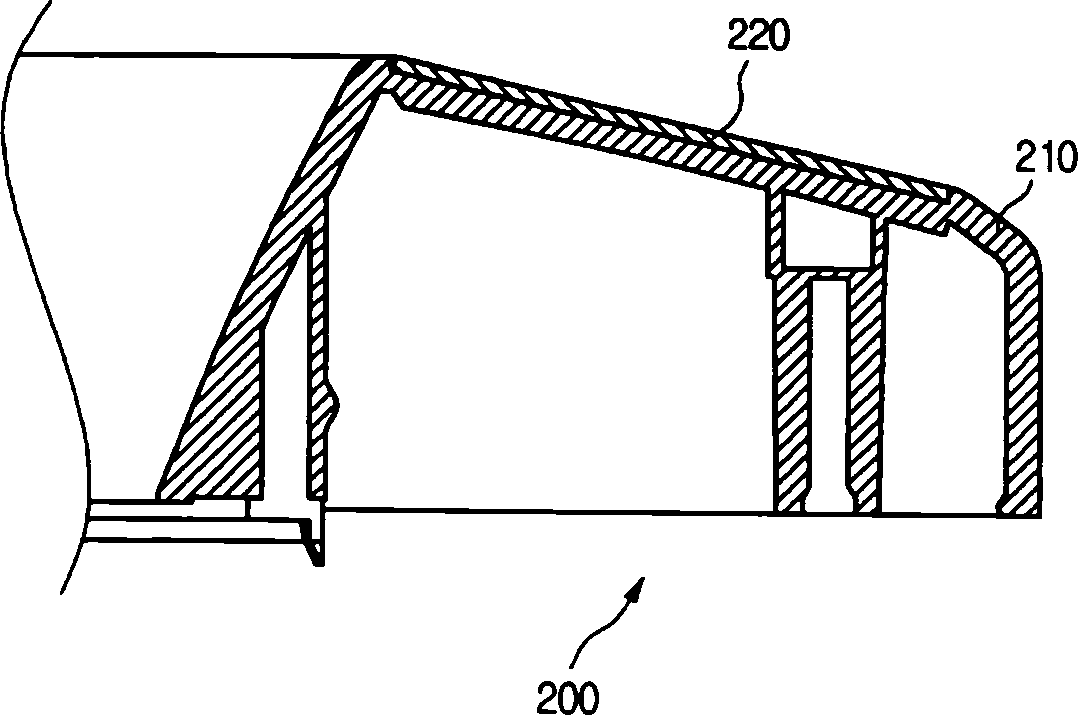

[0033] In order to achieve the above object, the present invention provides a door structure of a drum washing machine, which includes a door frame made by injection molding, and also includes that when the above door frame 210 is injection molded, the door frame 210 is attached to and inserted into the metal mold by an embedded injection molding method. The decorative strip 220 on the front part of the door frame; the door glass of transparent material attached to the edge of the inner peripheral surface of the door frame 210 .

[0034] The inner surface and / or the outer surface of the decoration strip 220 is provided with at least one fixing groove depressed with a certain depth.

[0035] The glossiness of the door frame 210 and the decoration strip 220 are different.

[0036] The decoration belt 220 is made of metal material.

[0037] Hereinafter, embodiments applicable to the present invention will be described with reference to the accompanying drawings.

[0038] figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com