Preparation method of spunlace non-woven fabric for dandelion mask

A technology of spunlace non-woven fabric and dandelion, which is applied in non-woven fabrics, textiles, papermaking, medical science, etc., can solve the problems of fiber application and other problems, and achieve the effects of increased strength, uniform tension, and uniform cloth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

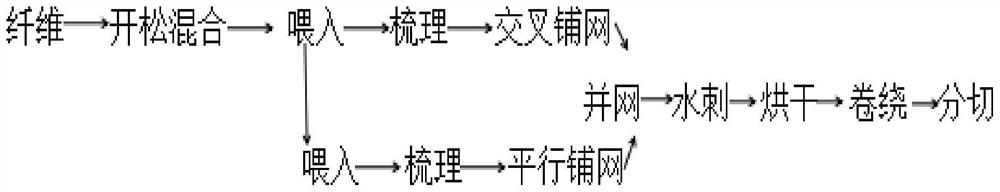

[0039] A method for preparing a spunlace non-woven fabric for a dandelion mask, which is characterized in that the dandelion fiber is combed into a net after being loosened and mixed evenly, and reinforced by a spunlace reinforcement technology. Then cut and wind to make the dandelion spunlace nonwoven material of required specifications, the specific steps are as follows:

[0040] 1) Preparation of cross-lapping layer

[0041]Using 100% dandelion fiber, using 3 automatic weighing machines for weighing, coarsely loosening the dandelion fiber raw material, after rough loosening, the raw material falls into the weighing hopper, and the front machine sets the ratio and controls according to the process requirements The material is dropped by the weighing hopper, after being opened again by two W1051 mixed cotton curtain openers, it is sent to the large warehouse mixed cotton box, and is vertically picked up and sent to the conventional cotton opener and the cotton condenser to op...

Embodiment 1

[0060] A kind of manufacture method of above-mentioned dandelion facial mask non-woven fabric, with reference to attached figure 1 , including the following steps:

[0061] (1) Preparation of cross-lapping layer: adopt 100% dandelion fiber, the average length of dandelion fiber is 38mm, and the average fineness is 1.67dtex, and the gram weight of the cross-lapping layer of gained is 28g / m 2 , the fiber raw materials are opened by the W1051 opener, carded by the AUTEFA carding machine and laid by the AUTEFA cross-lapper to obtain a cross-laid two-layer fiber web, and the output fiber web is sent to the drafting machine for drafting. Parameters: Carding machine feeding speed 0.63m / min, main cylinder speed 800m / min, output fiber web speed 50m / min, output fiber web unevenness 4%, web laying width 2.88m, number of web laying layers 2.

[0062] (2) Preparation of parallel laying layer 1: After rough opening of the dandelion fiber raw material, it is sent to JWF1024 multi-storage co...

Embodiment 2

[0067] A kind of manufacture method of above-mentioned dandelion facial mask non-woven fabric, with reference to attached figure 1 , including the following steps:

[0068] (1) Preparation of cross-lapping layer: adopt 100% dandelion fiber, the average length of dandelion fiber is 38mm, and the average fineness is 1.67dtex, and the grammage of the cross-lapping layer of gained is 24g / m 2 , the fiber raw materials are opened by the W1051 opener, carded by the AUTEFA carding machine and laid by the AUTEFA cross-lapper to obtain a cross-laid two-layer fiber web, and the output fiber web is sent to the drafting machine for drafting. Parameters: Carding machine feeding speed 0.50m / min, main cylinder speed 700m / min, output fiber web speed 40m / min, output fiber web unevenness 5%, web laying width 2.5m, number of web laying layers 2.

[0069] (2) Preparation of parallel laying layer 1: After rough opening of the dandelion fiber raw material, it is sent to JWF1024 multi-storage cotton...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com