Manufacturing method of honeysuckle hygienic care spunlace nonwoven fabric

A technology for spunlace non-woven fabrics and hygiene care, applied in the field of non-woven fabric manufacturing, can solve the problems of high cost, limited use, poor antibacterial effect, etc., and achieve the effects of small footprint, good dimensional stability, and pleasant mood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

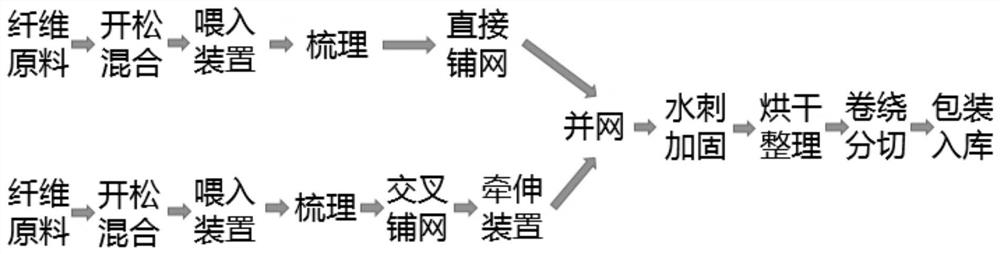

[0063] A kind of manufacture method of above-mentioned honeysuckle hygienic care non-woven fabric, with reference to attached figure 1 , including the following steps:

[0064] (1) prepare cross-lapping layer 2: adopt 100% wild honeysuckle viscose fiber, the average length of wild honeysuckle viscose fiber is 38mm, and average fineness is 1.67dtex, and 2 gram weights of gained cross-lapping layer are 26g / m 2 , the fiber raw materials are sequentially opened by the W1051A cotton opener, carded by the AUTEFA carding machine and laid by the AUTEFA 500889 cross-lapper to obtain the fiber web of the cross-laminated layer 2, and the output fiber web is sent to the drafting machine for drafting, Specific parameters: carding machine feeding speed 0.6m / min, main cylinder speed 1150m / min, output fiber web speed 60m / min, output fiber web unevenness 4%, web laying width 2.88m, number of web laying layers 2 , The draft ratio of the drafting machine is 2.2.

[0065] (2) Preparation of par...

Embodiment 2

[0069] A kind of manufacture method of above-mentioned honeysuckle hygienic care non-woven fabric, with reference to attached figure 1 , including the following steps:

[0070] (1) prepare cross-lapping layer 2: adopt 100% wild honeysuckle viscose fiber, the average length of wild honeysuckle viscose fiber is 38mm, and average fineness is 1.67dtex, and 2 gram weights of gained cross-lapping layer are 26g / m 2 , the fiber raw materials are sequentially opened by the W1051A cotton opener, carded by the AUTEFA carding machine and laid by the AUTEFA 500889 cross-lapper to obtain the fiber web of the cross-laminated layer 2, and the output fiber web is sent to the drafting machine for drafting, Specific parameters: carding machine feeding speed 0.30m / min, main cylinder speed 800m / min, output fiber web speed 50m / min, output fiber web unevenness 3%, web laying width 3.0m, number of web laying layers 2 , The draft ratio of the drafting machine is 1.5.

[0071] (2) Preparation of para...

Embodiment 3

[0075] A kind of manufacture method of above-mentioned honeysuckle hygienic care non-woven fabric, with reference to attached figure 1 , including the following steps:

[0076] (1) prepare cross-lapping layer 2: adopt 100% wild honeysuckle viscose fiber, the average length of wild honeysuckle viscose fiber is 38mm, and average fineness is 1.67dtex, and 2 gram weights of gained cross-lapping layer are 26g / m 2 , the fiber raw materials are finely opened by the W1051A cotton opener, carded by the AUTEFA carding machine and laid by the AUTEFA 500889 cross-lapper to obtain the fiber web of the cross-laminated layer 2, and the output fiber web is sent to the drafting machine for drafting , specific parameters: carding machine feeding speed 0.80m / min, main cylinder speed 1500m / min, output fiber web speed 80m / min, output fiber web unevenness 6%, web laying width 3.2m, number of web laying layers 2. The draft ratio is 2.4.

[0077] (2) Preparation of parallel laying layer 1: use 100%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com