Disposable full-biodegradable transparent straw and preparation method thereof

An all-biological, one-time-use technology, used in table utensils, applications, home utensils, etc., can solve the problems of poor transparency, low break rate, high break rate, and achieve low cost, low break rate, and high transparency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

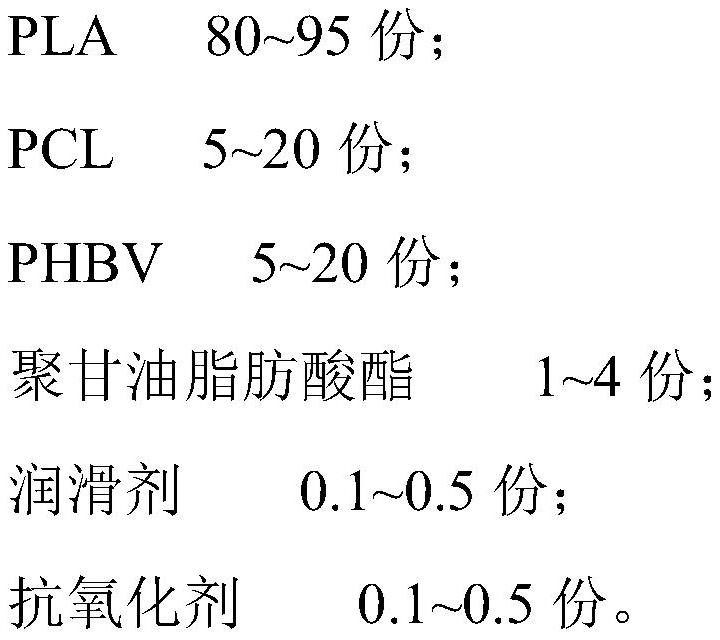

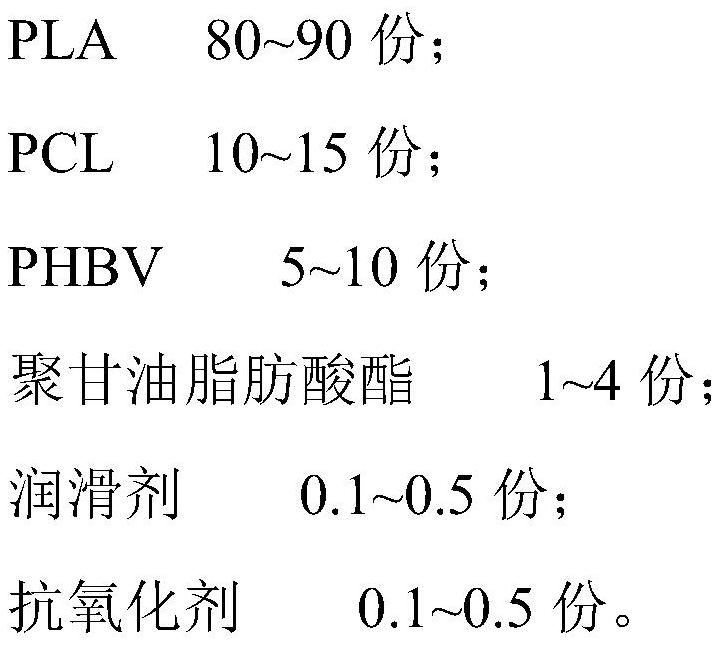

Method used

Image

Examples

Embodiment 1

[0029] 80 parts by mass of PLA, 10 parts by mass of PCL, 5 parts by mass of PHBV, 4 parts by mass of polyglycerol fatty acid ester, 0.5 parts by mass of oleic acid amide as a lubricant, and 0.5 parts by mass of 1076 as an antioxidant were added to the mixer and mixed The mixed material is added to a twin-screw extruder with a length-to-diameter ratio of 48:1, extruded, drawn, cooled, and pelletized to obtain a special resin for fully biodegradable transparent straws. The temperature of the barrel is 160 degrees. Head temperature is 165 degrees;

[0030] Put the special resin for fully biodegradable transparent straws into the straw manufacturing unit for extrusion, shaping, pulling, cooling, and pipe cutting to obtain fully biodegradable transparent straws. The screw length-to-diameter ratio of the straw manufacturing unit is 32:1. The barrel temperature is 190 degrees , the die head temperature is 180 degrees.

[0031] The deviations of the inner and outer diameters of the o...

Embodiment 2~4

[0034] According to the process steps of Example 1, the addition amount of PCL was adjusted to 5 parts, 15 parts, and 20 parts respectively, and other conditions remained unchanged, and transparent straws were obtained. %, 85%, 80%.

Embodiment 5~7

[0036] According to the process steps of Example 1, the addition amount of PHBV is adjusted to 5 parts, 15 parts, and 20 parts, and other conditions remain unchanged, and transparent straws are obtained, and the breakage ratios are 95, 100, and 100 respectively, and the transparency is 90% respectively. , 90%, 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com