Glass fish bowl and its manufacturing method

A manufacturing method and glass technology, applied in fish farming, application, animal husbandry, etc., can solve the problems of increased possibility of leakage, impact on sturdiness, obsolete style, etc., to achieve enhanced sturdiness, elegant temperament, and lively image Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

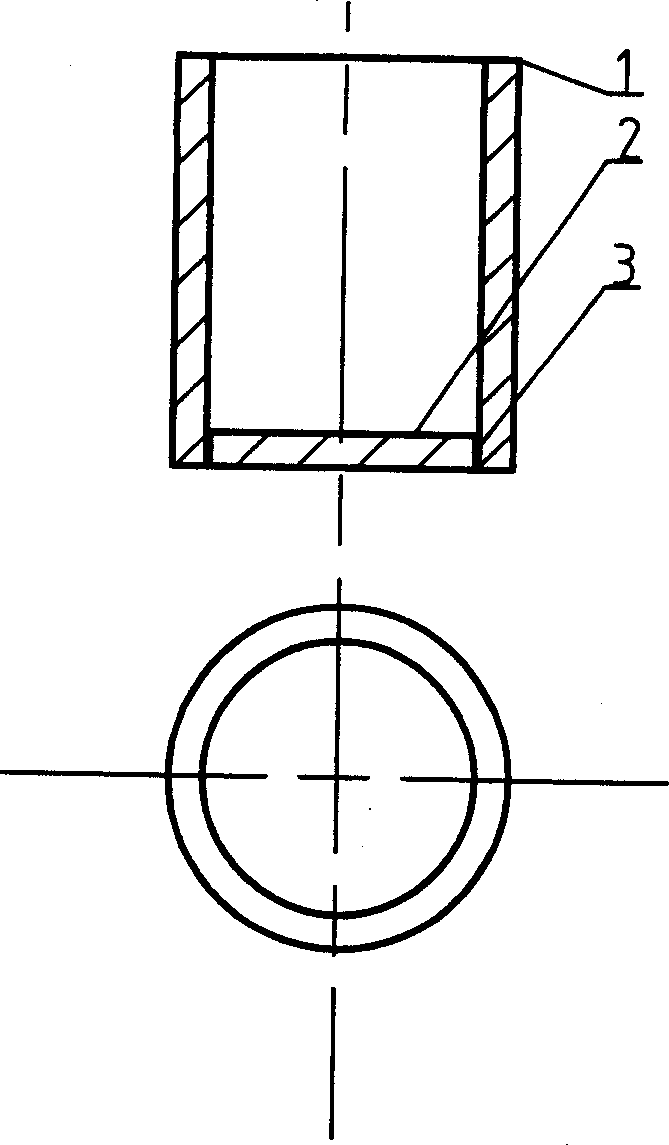

[0038] Such as figure 1 Shown, a kind of cylinder-shaped glass fish tank is formed by hot-bending the flat glass into the circular flat glass tank bottom 2 made by the traditional method of the outer cylinder tube 1 and the glass glue 3 bonding and sealing at their seams.

[0039] There are three ways to make it:

[0040] 1. Curling forming method: such as Figure 4 shown.

[0041] (1) Cut the 10mm flat glass into a rectangle (cylinder barrel 1) and a circle (cylinder bottom 2) according to the required size;

[0042] (2) steel cylindrical shape steel mold 9 etc. are placed in hot bending furnace 8, the flat glass of cylinder barrel 1 is placed on the top of supporting roller 6 steel mold 9 cylinders;

[0043] (3) When the temperature of the hot bending furnace 8 is raised to 500°C, after the glass is softened, it is heated locally with the electric furnace wire 7 to further soften the glass of the cylinder 1, and one end of the softened glass plate 5 is pressed with a pres...

Embodiment 2

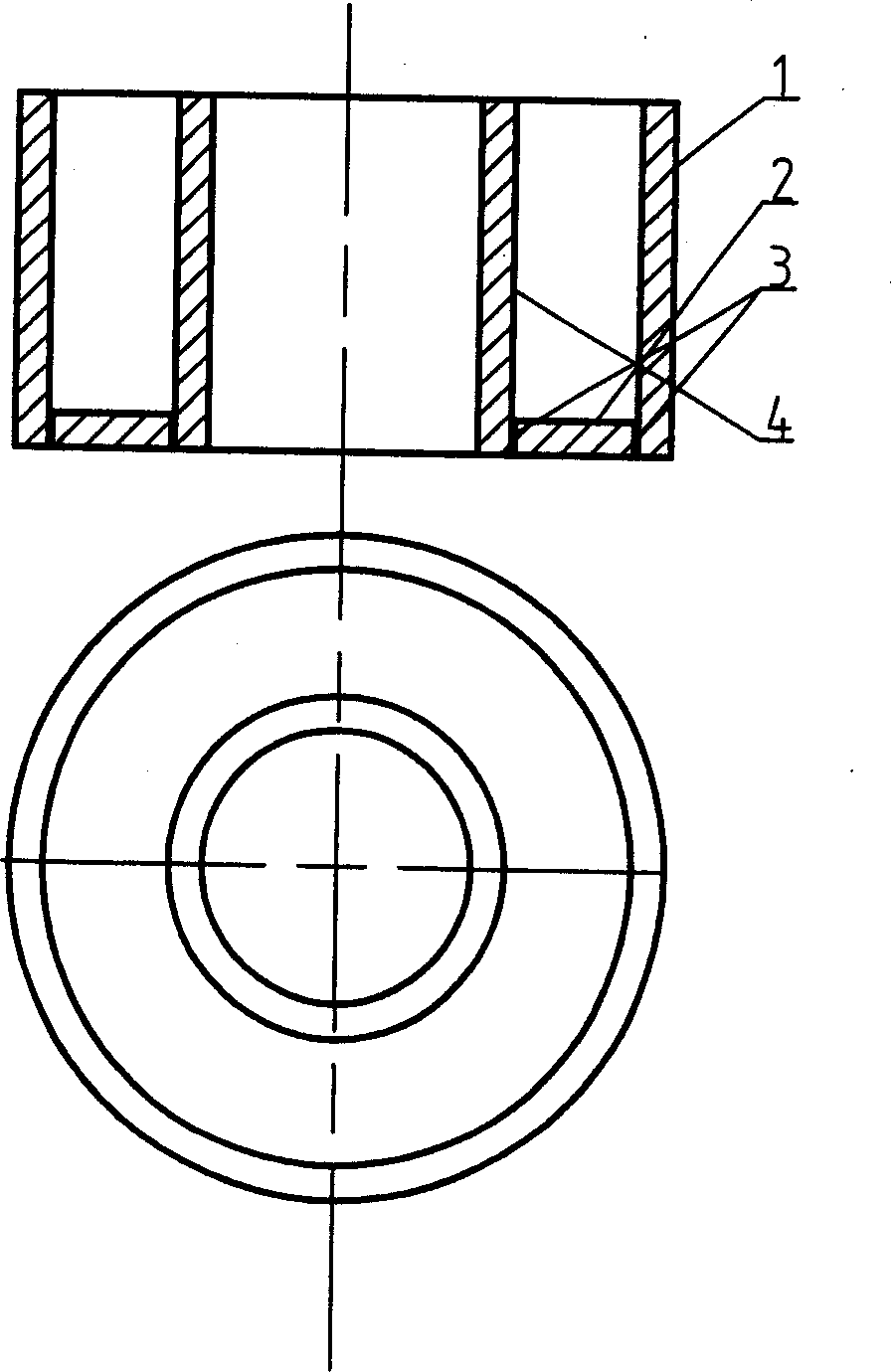

[0054] A hollow cylindrical glass fish tank such as figure 2 Shown, it is made of outer cylinder circumference 1, inner cylinder circumference 4, hollow circular cylinder bottom 2 and adhesive seam glass bonding 3.

[0055]Referring to the three manufacturing methods in Example 1, the inner cylinder 1 and the outer cylinder 4 are manufactured separately, then cooled, bonded and sealed. Others are the same as embodiment 1.

Embodiment 3

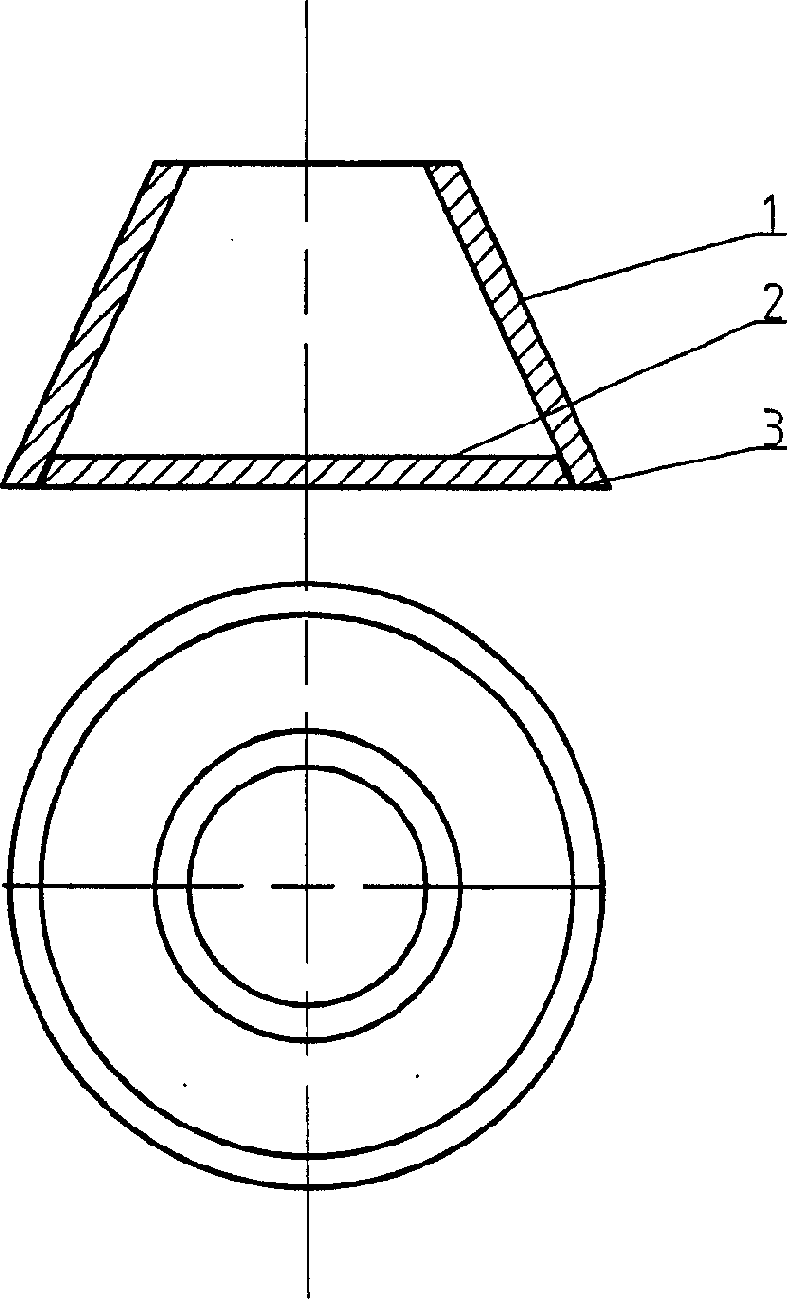

[0057] A frustoconical (truncated cone) glass fish tank, such as image 3 As shown, it consists of a truncated right conical cylinder 1, a cylinder bottom 2 and a joint glass 3.

[0058] The steel mold 9 is in the shape of a truncated right cone, and other method steps and process parameters are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com