Thermodynamic cycle and device

A thermodynamic cycle and pressure technology, applied in steam engine installations, machines/engines, mechanical equipment, etc., can solve problems such as low thermal efficiency, energy waste, energy crisis, etc., and achieve the effect of high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

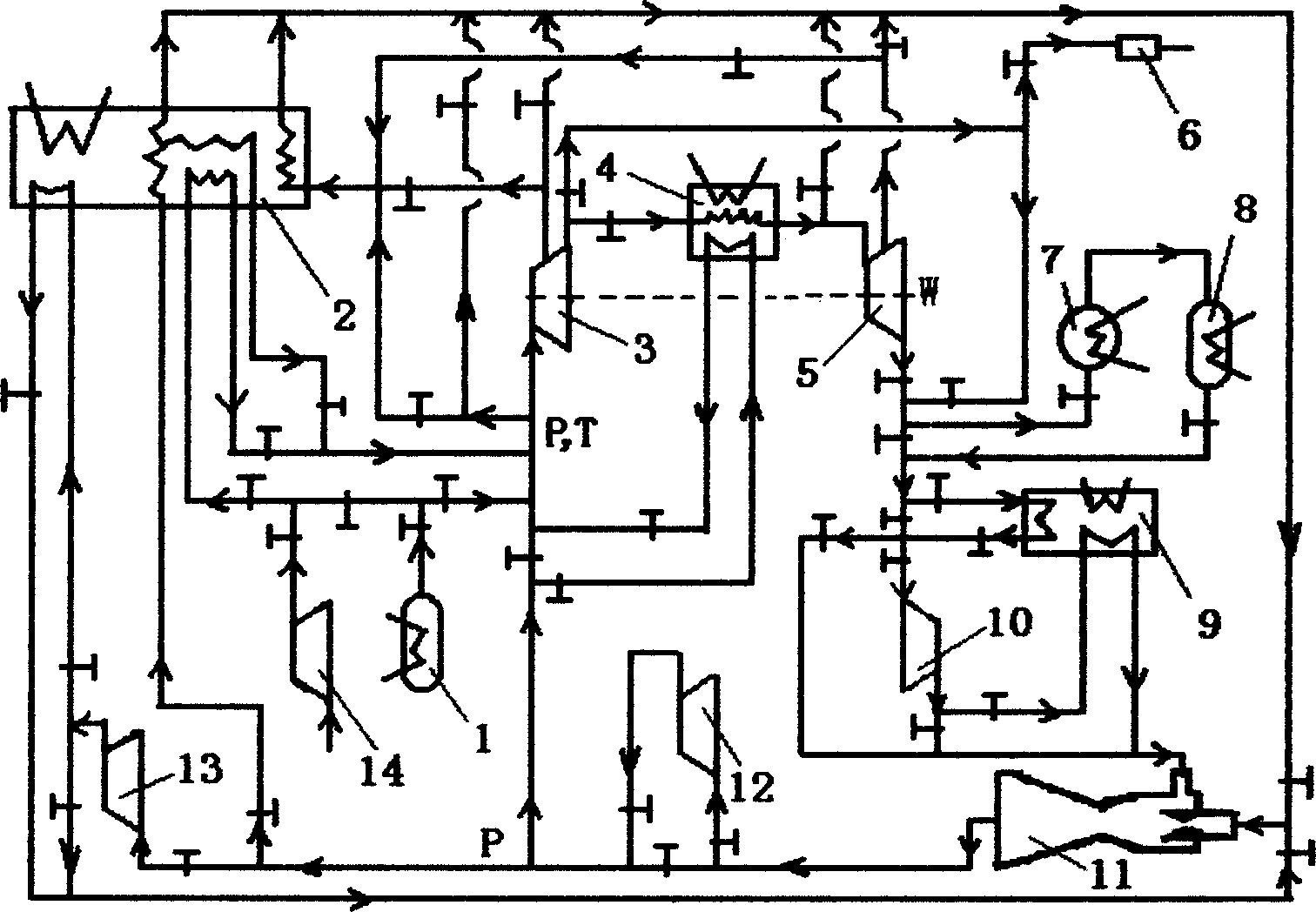

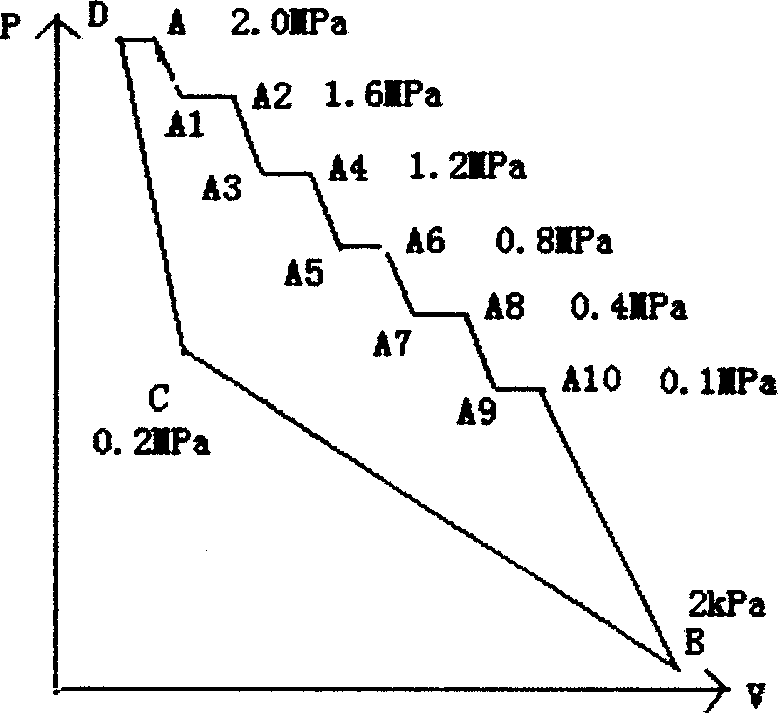

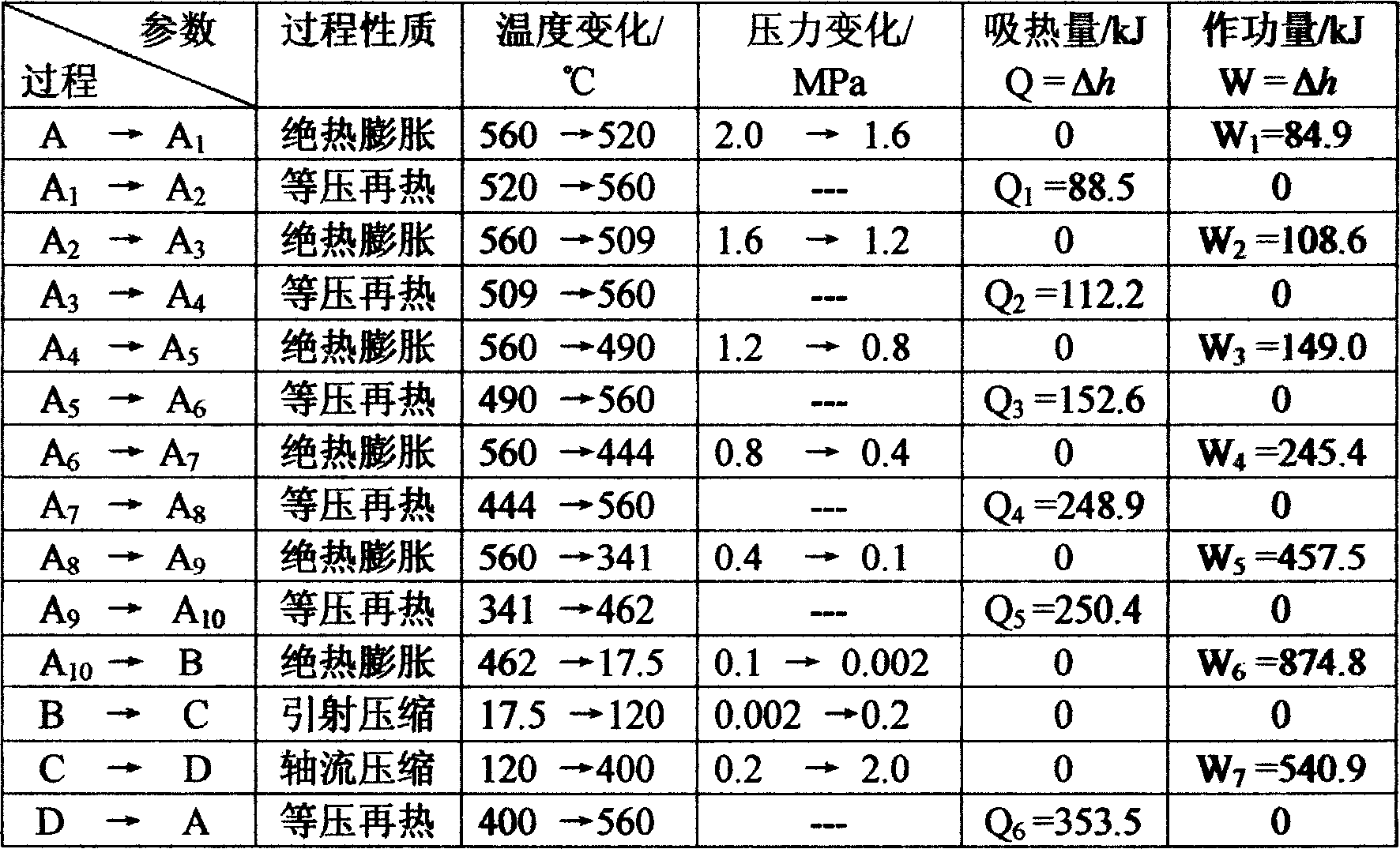

[0022] Embodiment 1: In this embodiment, water vapor is used as a working medium. The system is evacuated by the vacuum pump (6), and the steam generator (1) generates water vapor with an initial pressure of 2.0MPa, which enters the superheater (2) and is heated to become superheated steam with an initial temperature of 560°C, and then enters the turbine (3, 5) Expansion works, and 5 reheat cycles are carried out in the middle. The parameters of each reheat cycle are shown in the appendix figure 2 and the table below, and make the dryness of the exhaust gas coming out from the turbine (5) reach 100%, the exhaust gas (2kPa, 17.5°C) is reheated steam (0.4MPa, 560°C) for the fourth time in the ejector (11) ℃) under the action of ejection to initially compress into 0.2MPa, 120℃ saturated steam, then compressed to 0.4MPa by the compressor (12), and then heated to 560℃ by the superheater (2) to re-reach the initial steam parameters, Enter the next cycle. The parameters of each pr...

Embodiment 2

[0037] Embodiment 2: On the basis of the cycle of Embodiment 1, the heat pump (9) is introduced to absorb heat from the cold source to generate hot water with a temperature of 80 ° C. The exhaust gas is firstly exchanged with the hot water of the heat pump (9) to be heated to 80°C, and then enter the ejector (11) to compress to 0.2MPa, 120°C saturated steam. All the other processes are the same as in Example 1. Then the heat absorbed by the unit working fluid from the heat pump (9) is

[0038] Q hp =Cp(T 2 -T 1 )

[0039] =1.0×(80-17.5)

[0040] =62.5(kJ / kg)

[0041] That is, the enthalpy of exhaust gas after heating becomes h 4 =2533.5+62.5=2596 (kJ / kg)

[0042] Then the mass ratio in the ejector is m 0 / m 1 =(h 1 -h 4 ) / (h 4 -h 3 )

[0043] get m after substituting 1 =10.9%, m 0 = 89.1%.

[0044] That is, the actual heat absorbed by the heat pump is

[0045] Q 8 = m 0 Q hp

[0046] =0.891×62.5

[0047] =55.7(kJ)

[004...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap