Repair apparatus for coke oven

一种焦炭炉、伸缩装置的技术,应用在炉、衬里修复、炉子组件等方向,能够解决修补范围局限、不能避免炉壁不能修补、成本高等问题,达到扩大修补范围的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, the present invention will be described in detail based on the embodiments shown in the drawings.

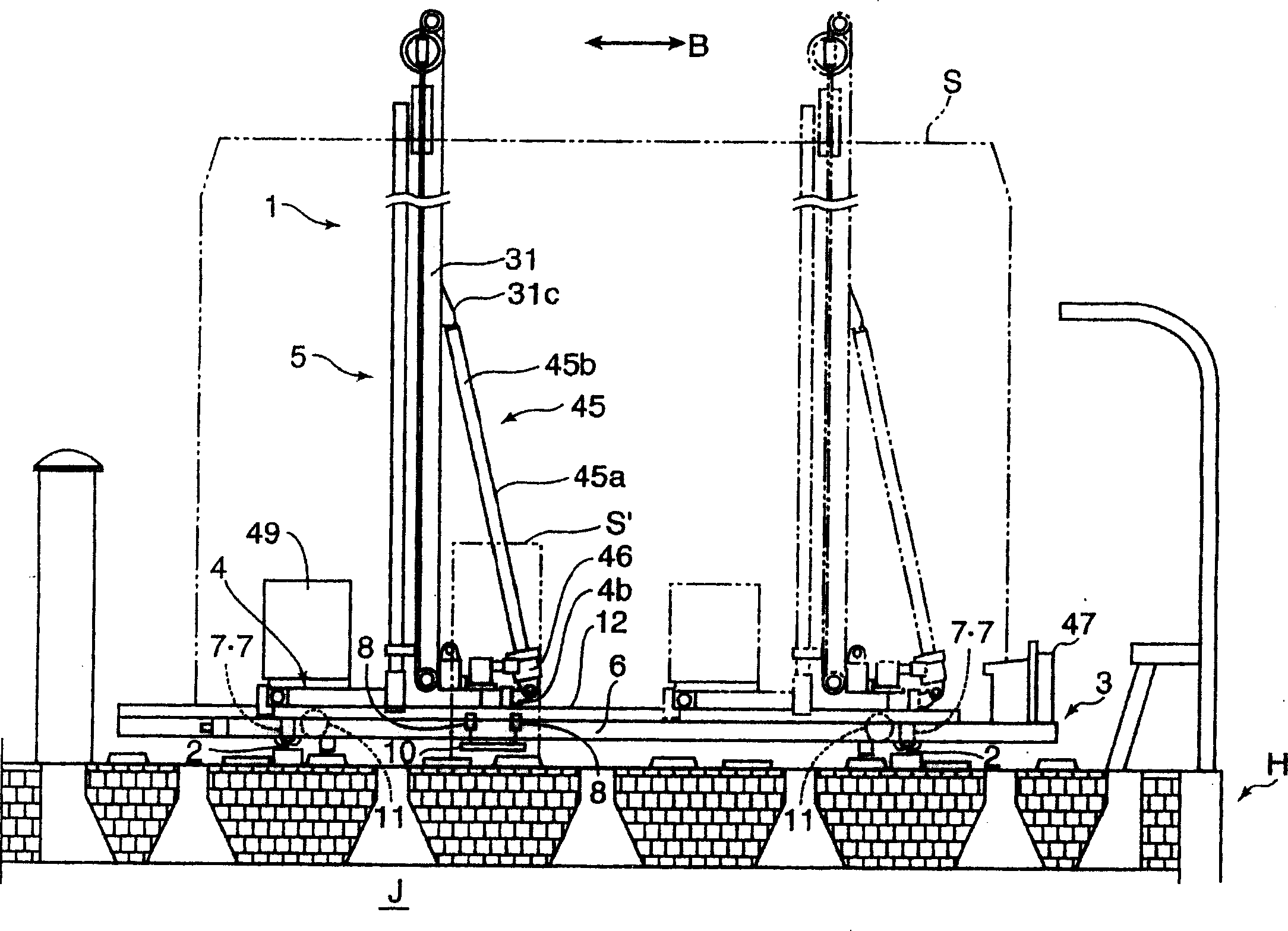

[0048] figure 1 Shown is the repairing device of the present invention arranged on the coke oven H furnace. In addition, a coal charging vehicle for charging coal into the carbonization chamber J is disposed on the furnace, and its outline is indicated by a two-dot chain line in the figure. In addition, S' is a channel that runs through the furnace group in the coal charging car S.

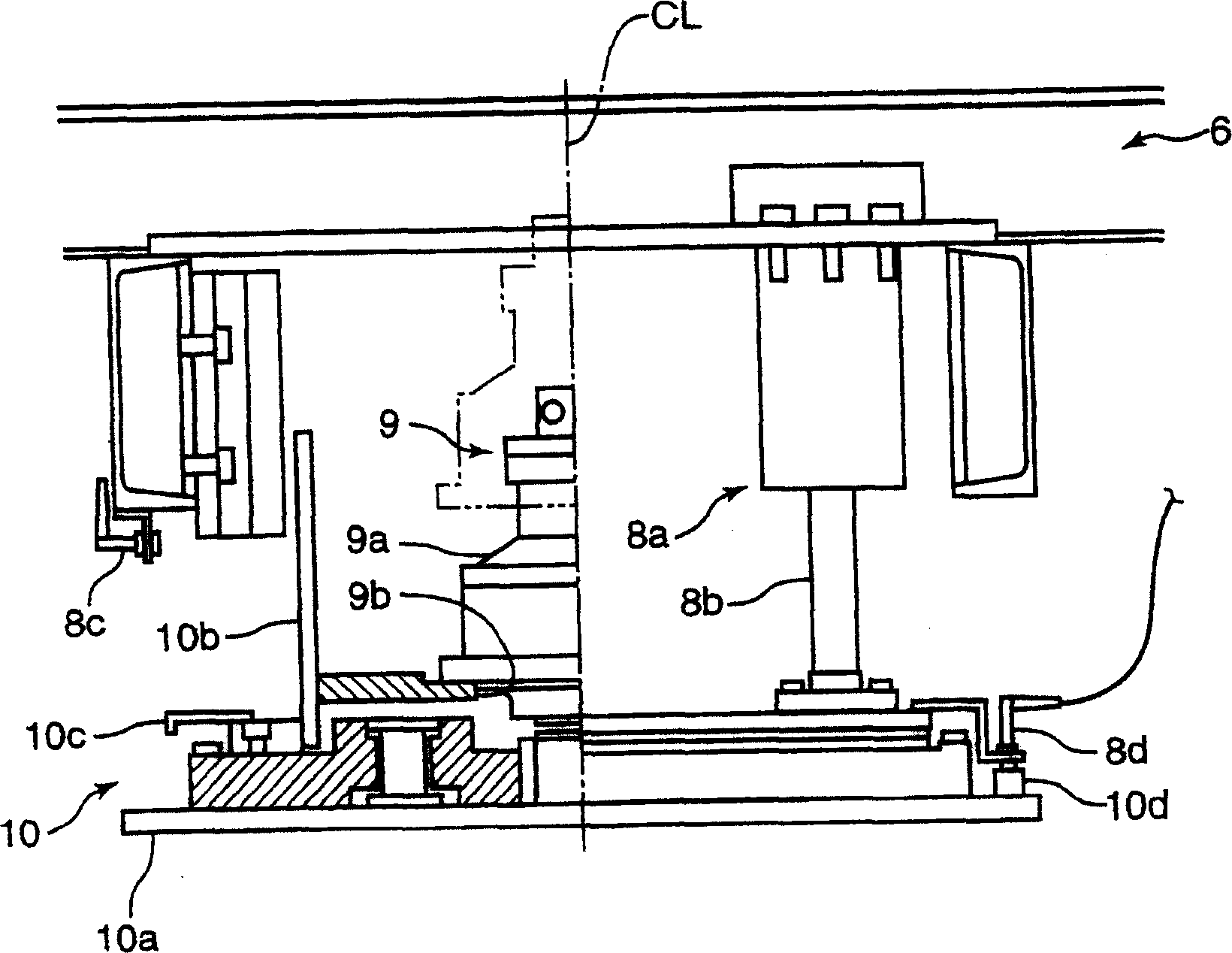

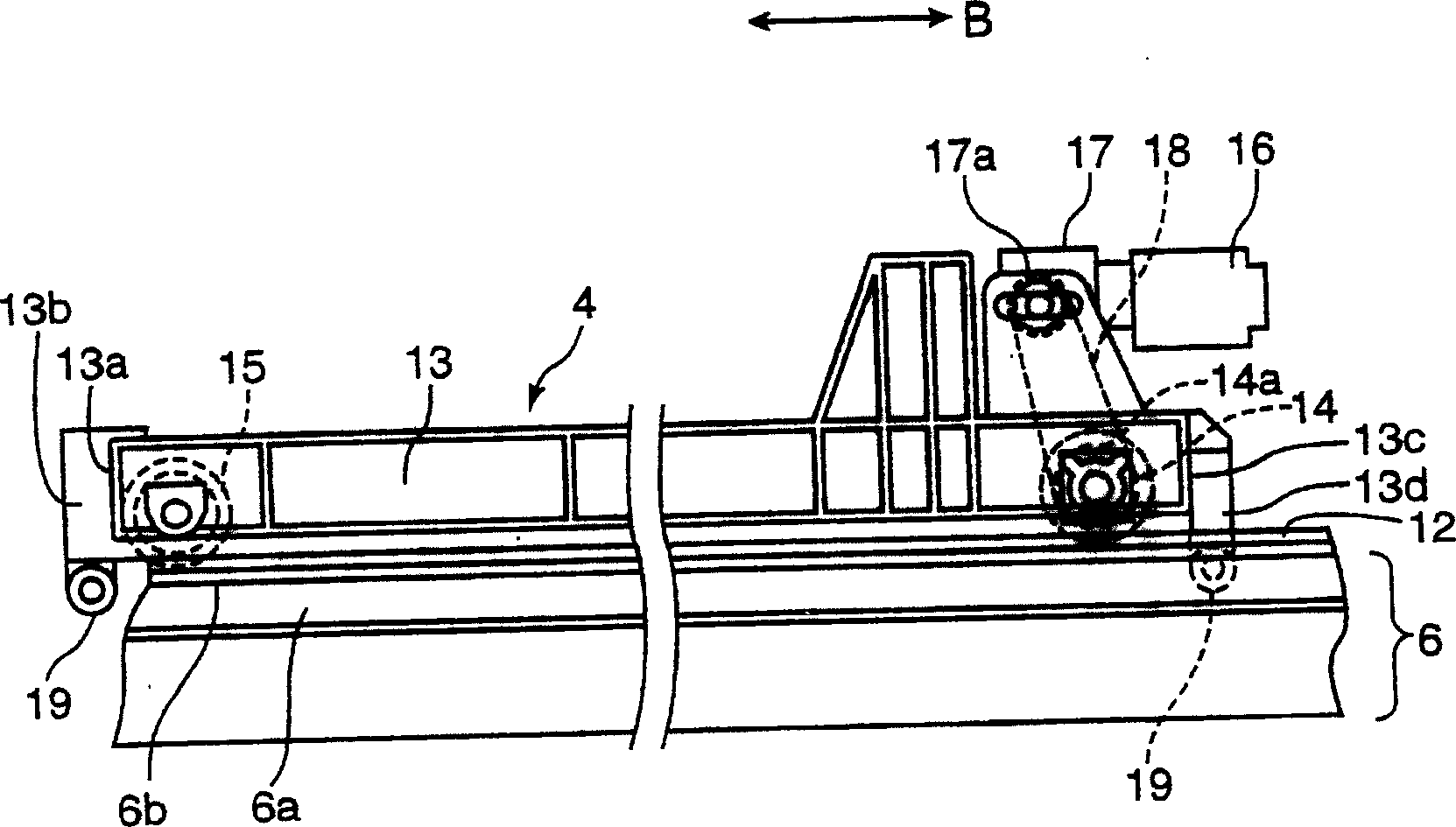

[0049] In this figure, the repair device 1 mainly includes: on the rails 2, 2 laid on the furnace along the direction of the furnace group, a walking trolley 3 that walks across them; A traverse trolley 4 traverses in the longitudinal direction (arrow B direction); and a working device 5 mounted on the traverse trolley 4 .

[0050] The frame 6 of the above-mentioned walking trolley 3 is, for example, a frame that assembles C-shaped steel or I-shaped steel into a window frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com