Secondary cyclone dust separating cup of vacuum cleaner

A cyclone-type vacuum cleaner technology, applied in the field of centrifugal vacuum cleaner air and dust separation device, can solve the problems of complex manufacturing process, inconvenient dust dumping and cleaning, troublesome use and cleaning, etc., and achieve simple structure, saving manufacturing cost, high performance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

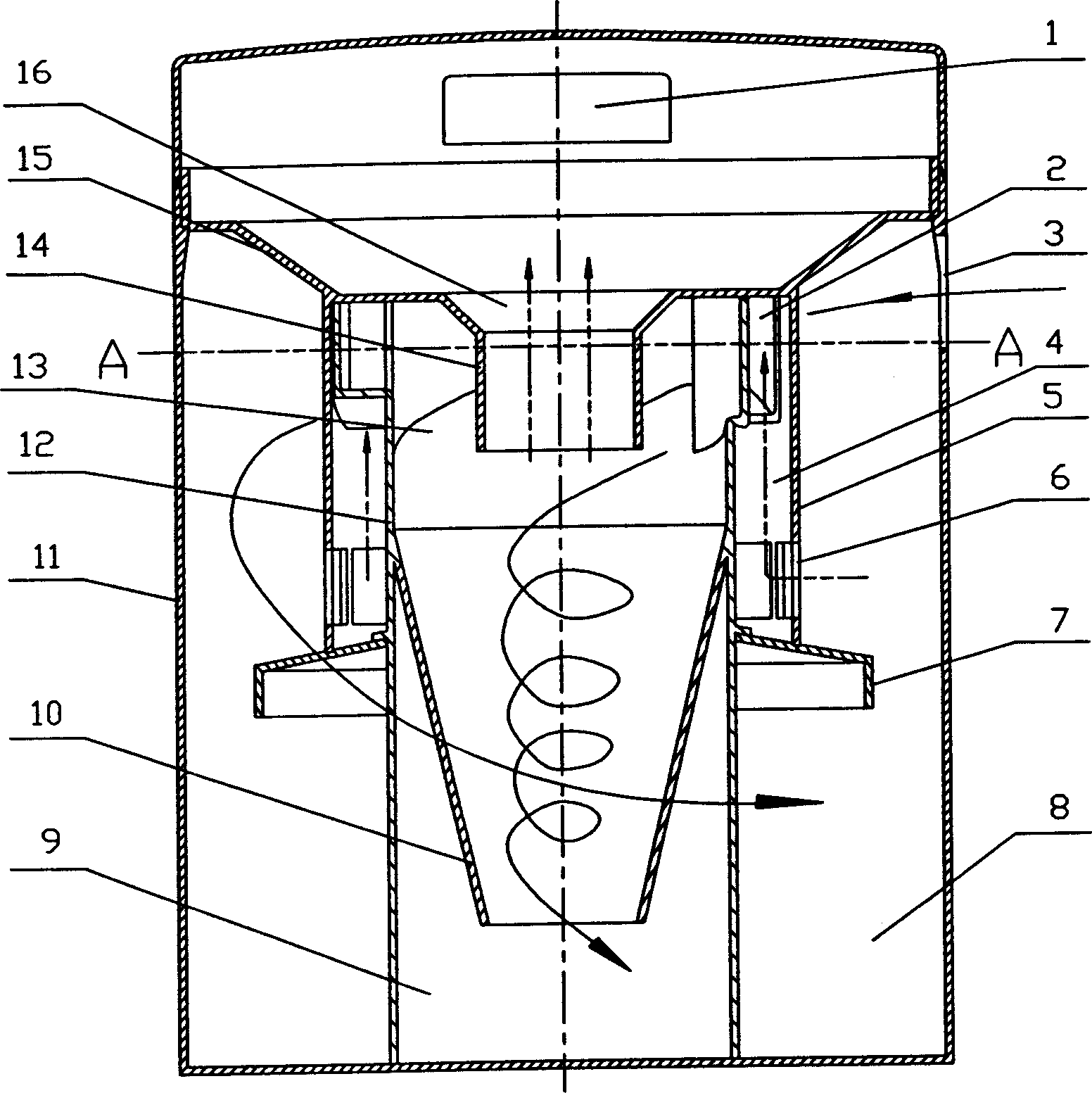

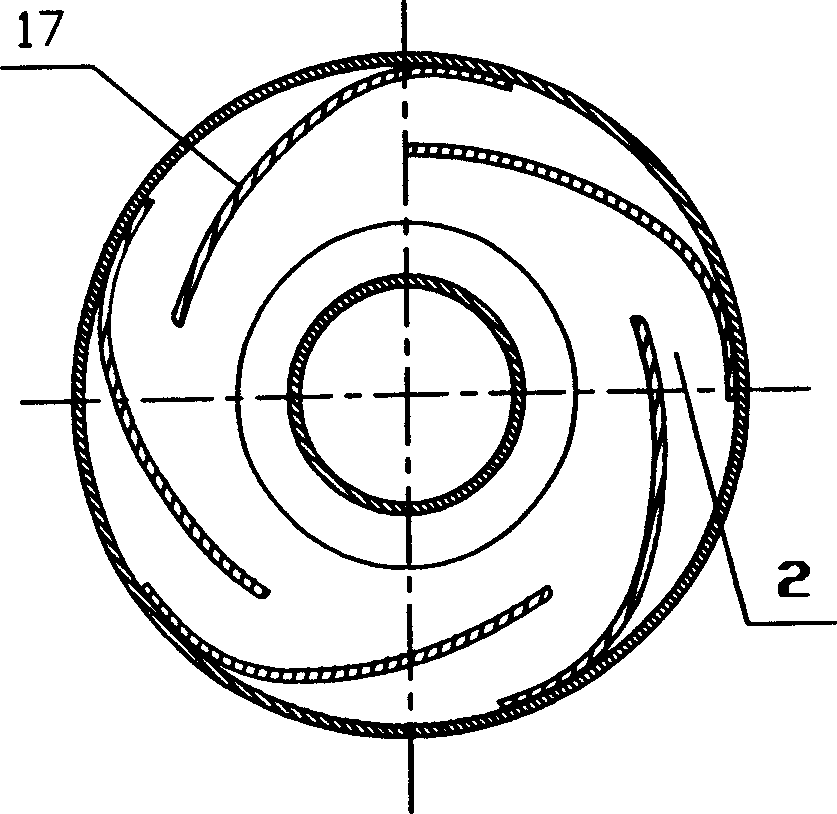

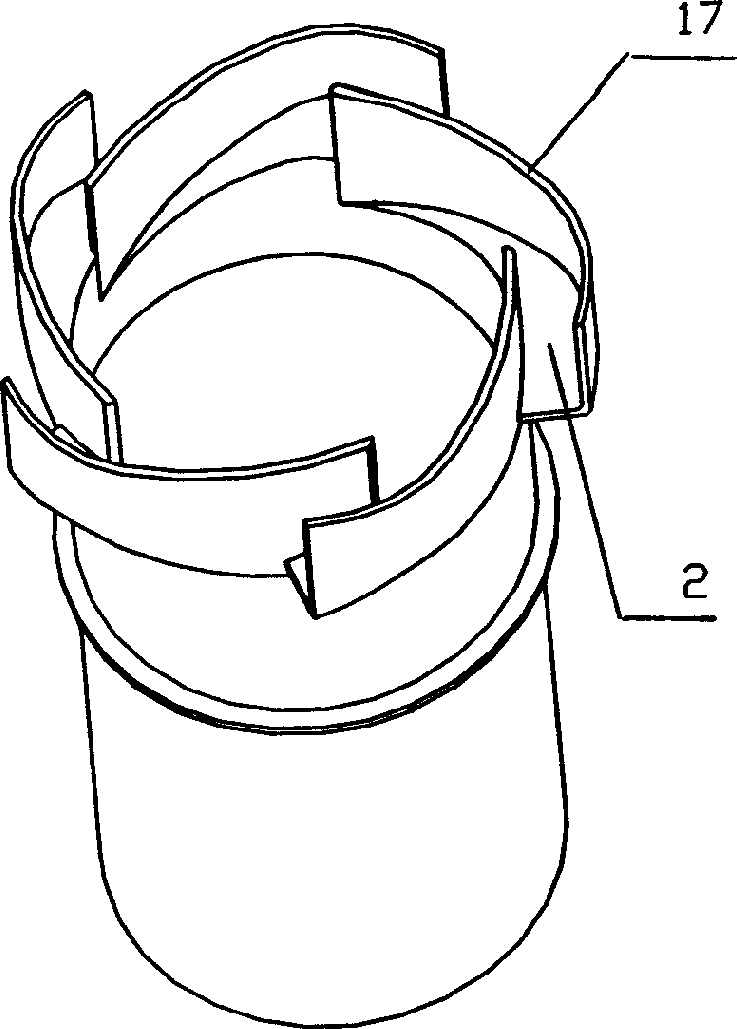

[0014] As shown in the figure, the secondary cyclone-type separation dust cup of the vacuum cleaner includes a cup body 11, a dust cup air inlet 3 opened on the peripheral wall of the cup body tangent to it, and a dust cup opened on the dust cover that is closed with the cup body. Air outlet 1 and the separator placed in the dust cup. The separator is provided with an outer cylinder 5 connected between the connecting bracket 15 and the isolation cover 7, and the lower end of the outer cylinder is alternately provided with a separator air inlet 6 lower than the dust cup air inlet 3. The separator air inlet 6 It can be rectangular, circular and arranged in a uniform ring. A trumpet-shaped isolation cover 7 is provided below the separator air inlet 6 . An inner cylinder 12 is arranged coaxially at the center of the outer cylinder 5 , the top of the inner cylinder is connected to the connecting bracket 15 , and the bottom of the inner cylinder is connected to the bottom of the du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com