Floating ballast bed with height monitoring device

A technology of floating ballast bed and monitoring device, applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc., can solve the problems of multiple manpower and material resources, prone to errors, inconvenient measurement, etc., and achieves saving manpower and material resources, strong safety, The effect of eliminating security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

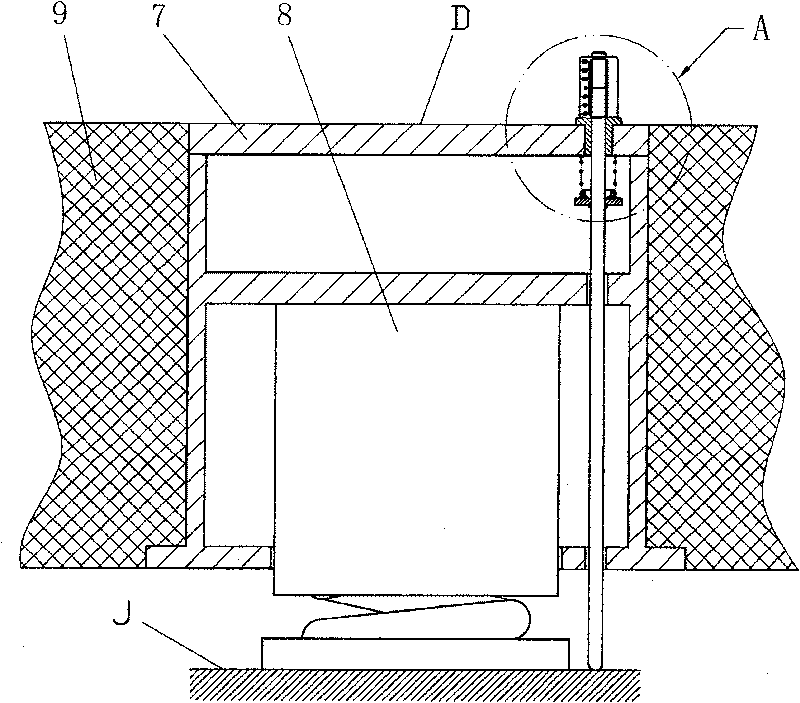

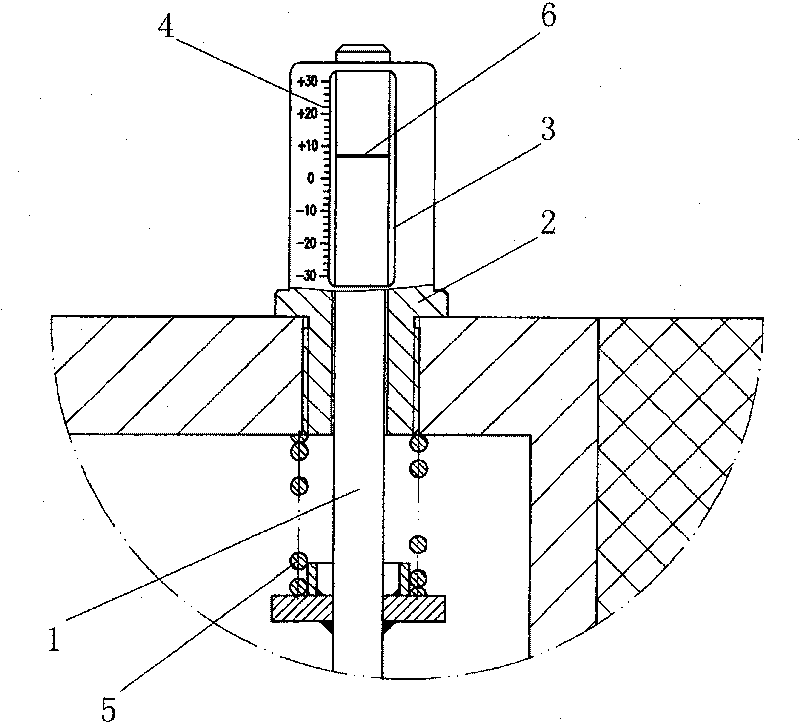

[0020] Such as figure 1 , figure 2 As shown, the device for monitoring the height change of the elastic support member of the present invention includes a mark post 1 and a positioning support 2. The positioning support is provided with an observation hole 3 and a scale line 4 for marking the height, and the mark post 1 is provided with a benchmark for reading Line 6. The outer casing 7 of the shock absorber is preset in the subway track bed 9 elastically supported by the shock absorber 8, and the top surface of the casing 7 and the upper surface of the subway track bed 9 are on the same horizontal plane. The distance of the base surface will change with the change of the compression amount of the shock absorber 8, so the horizontal plane is a dynamic reference plane D, and the base surface that remains static constitutes the static reference plane J, at this time the subway track bed 9 is the elastic support members. Utilize the threaded part provided at the lower part of...

Embodiment 2

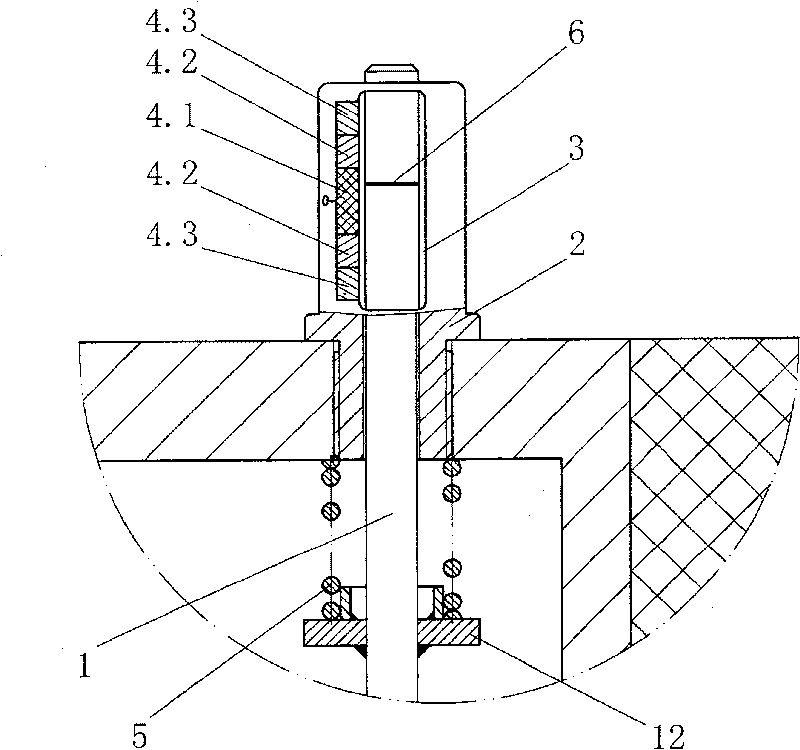

[0024] The difference between this embodiment and Embodiment 1 is that different color partitions are set on the positioning support 2 to replace the scale marks to mark the height. Such as image 3 As shown, on the surface of the positioning support 2 with the zero scale as the center, green, yellow, and red colors are set in turn to mark the working range of the ballast bed: the green color is the reasonable working area 4.1; the yellow color is the warning area 4.2; the red color is the failure area 4.3. The span ranges of the above-mentioned areas should be set reasonably after calculation according to the actual situation. When the reference line 6 points to different color areas, we can know the working status of the elastic support (shock absorber in the embodiment) in time according to the meaning represented by the color areas, so as to make maintenance adjustments in time to ensure safety. If it is yellow, observation should be strengthened, and when it is red, it s...

Embodiment 3

[0026] The device for monitoring the height change of the elastic support member according to the present invention can also be directly arranged on the member. Such as Figure 4 , Figure 5 As shown, a precision measurement platform 9 is an elastic support member, and a catheter 11 is preset in the equipment foundation. The measurement and positioning device of the monitoring device of the present invention includes a positioning support 2 and a zero point adjustment nut 10, and the lower end of the positioning support 2 is fixed on the top of the pipe 11 by interference fit. The benchmark post 1 runs through the positioning support 2 and the zero point adjustment nut 10 and is set in the conduit 11 , and its bottom end is in contact with the base surface of the supporting vibration isolator 8 . The benchmark post 1 is also provided with a scale line 4 for marking the height. At this time, the upper surface of the vibration-prone equipment foundation 9 is the dynamic datum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com