Phase shift photomask and method for improving printability of a structure on a wafer

A photomask and wafer technology, applied in the field of photolithography, can solve the problems of sub-wavelength line structure quality degradation, affect the phase shift characteristics of etching and non-etching areas, etc., and achieve the effect of enhancing light intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

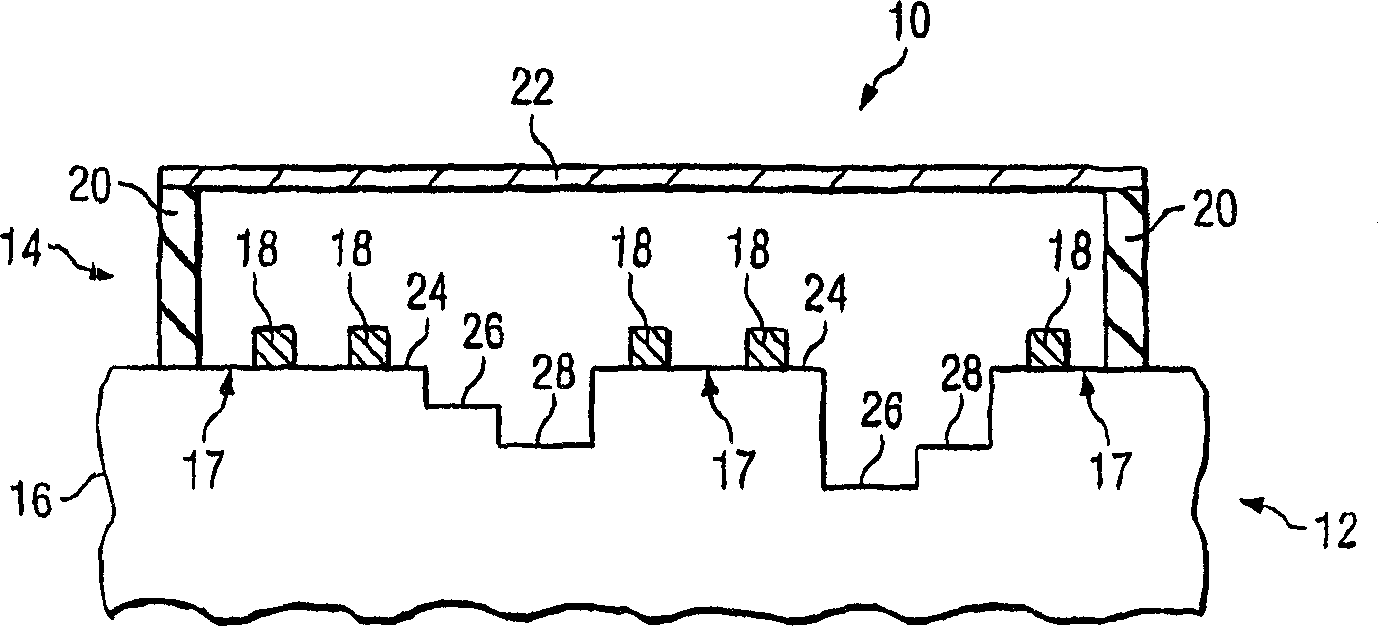

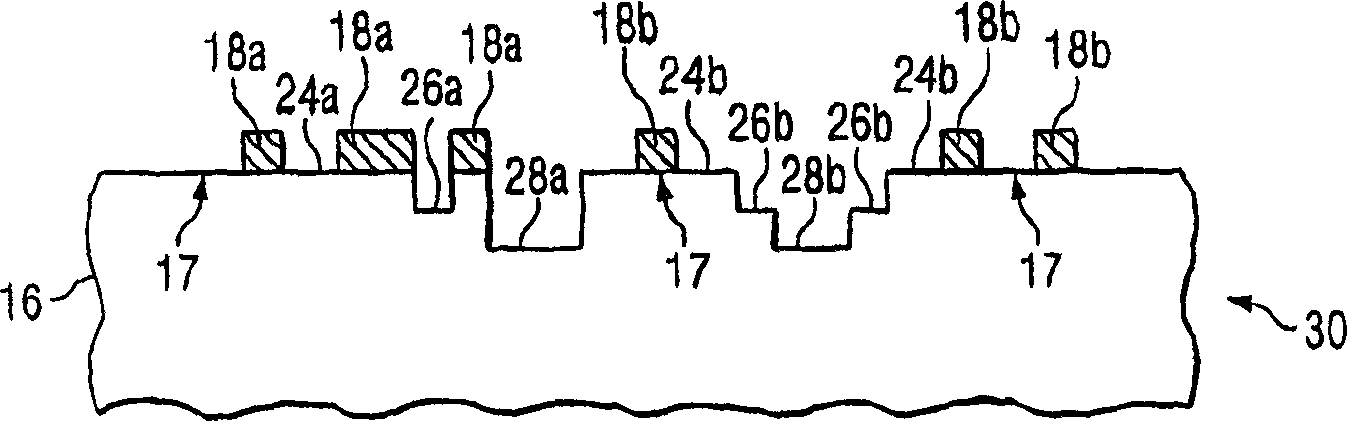

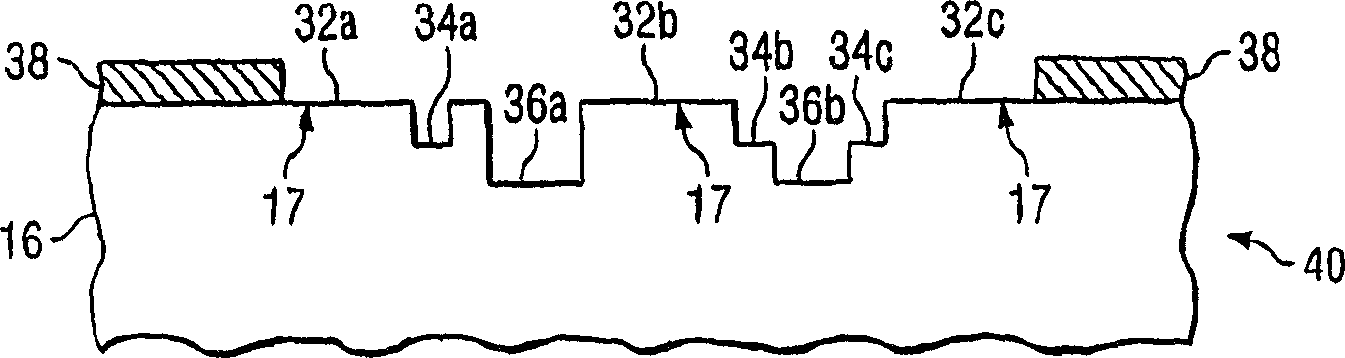

[0023] by reference Figure 1 to Figure 6 , that the preferred embodiments of the present invention and their advantages are best understood, wherein like reference numerals are used to identify like and corresponding parts throughout the drawings.

[0024] figure 1 A cross-sectional view of an exemplary photomask assembly 10 is shown. Photomask assembly 10 includes pellicle assembly 14 mounted on photomask 12 . The phase shift window (PSW) 24 of substrate 16, pattern layer 18, 0 degree, orthogonal PSW 26 and 180 degree PSW 28 forms photomask 12, and photomask 12 is called reticle or mask again, it Available in a variety of sizes and shapes including, but not limited to, round, rectangular, and square. The photomask 12 can also be any photomask including, but not limited to, a one-time master mask, a five-inch reticle, a six-inch reticle, a nine-inch reticle, or any other reticle that can be used to pattern a circuit A reticle of the appropriate size is projected onto a se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com