Numerical Control system of numerical controlled press for shaping ship plates

A sheet metal forming and numerical control system technology, applied in the field of hydraulic presses, can solve problems such as low automation, trivial sheet processing technology, and high human resources, and achieve the effects of reducing mental and physical labor, simplifying control methods, and high automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The numerical control system of the hull plate forming numerical control press of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

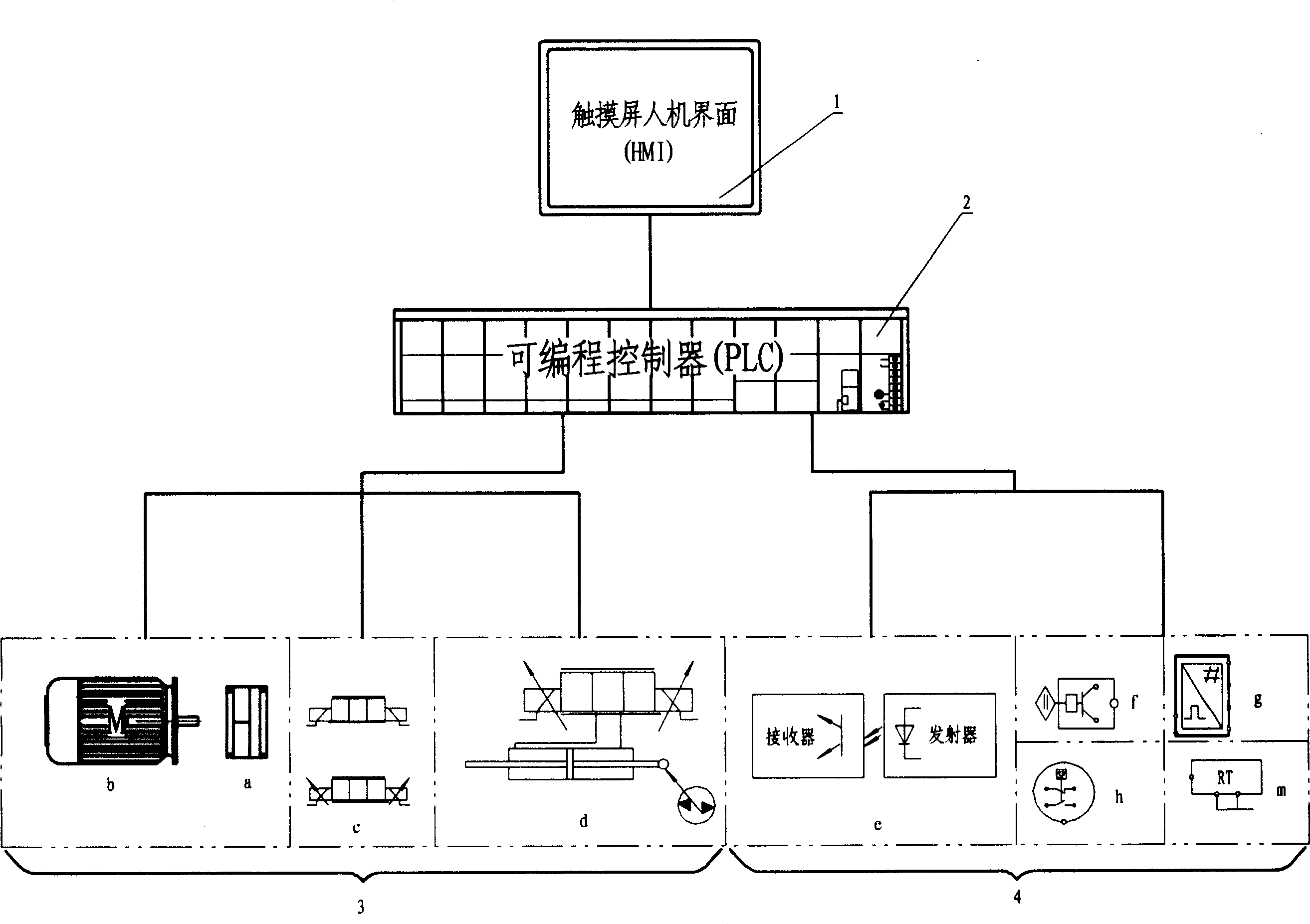

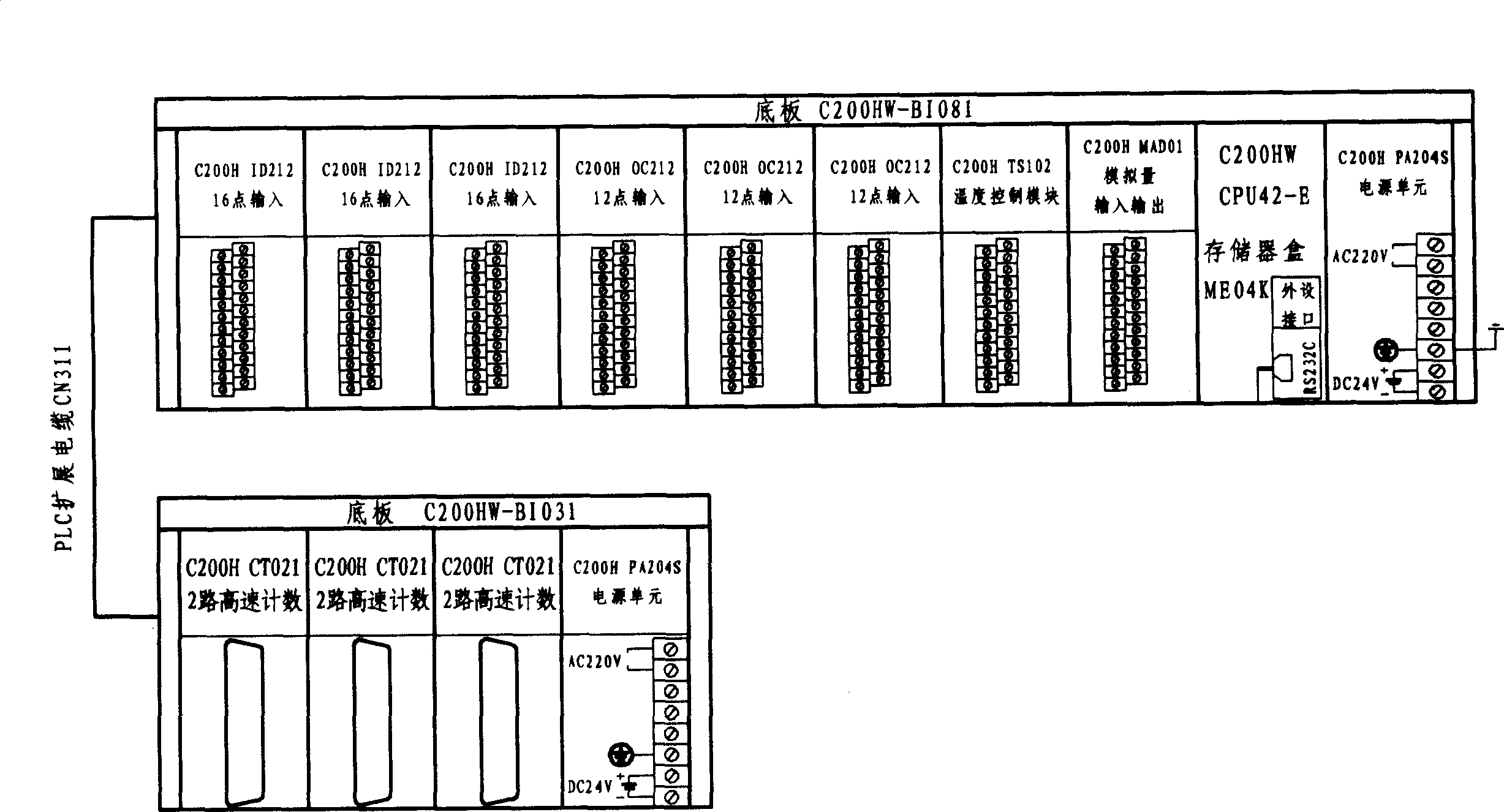

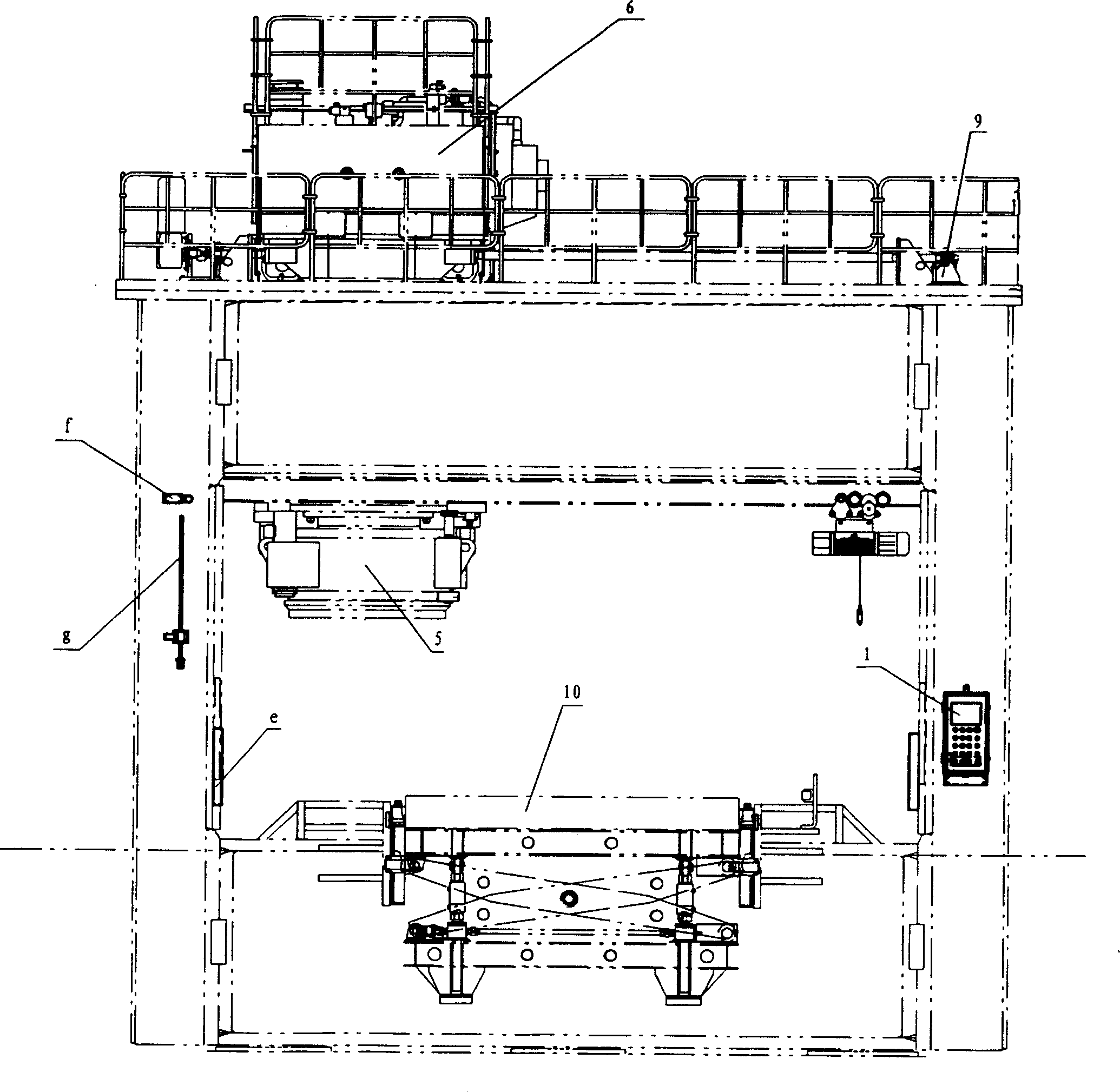

[0026] like figure 1 The numerical control system of the hull plate forming numerical control press shown in the figure includes a management layer, a control layer and a physical layer, wherein the management layer is HMI touch screen human-machine interface 1, the control layer is PLC programmable controller 2, and the physical layer is set by The actuator 3 and the detection mechanism 4 on the press are composed. The management layer is connected with the control layer, which can conveniently realize man-machine dialogue and help the operator understand the working status of the machine tool to achieve the purpose of simplifying the control method, that is, the working status of each component of the physical layer can be displayed on the touch screen, and ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com