Air conditioner condensation water divided flow box

A technology for air conditioners and condensed water, which is applied in the direction of preventing condensed water, etc. It can solve the problems of ground water that cannot be properly and thoroughly treated, increased energy consumption, damp and mildew on the wall, etc., to avoid damp and mildew on the wall, and effectively Conducive to safety and sanitation, the effect of eliminating direct discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

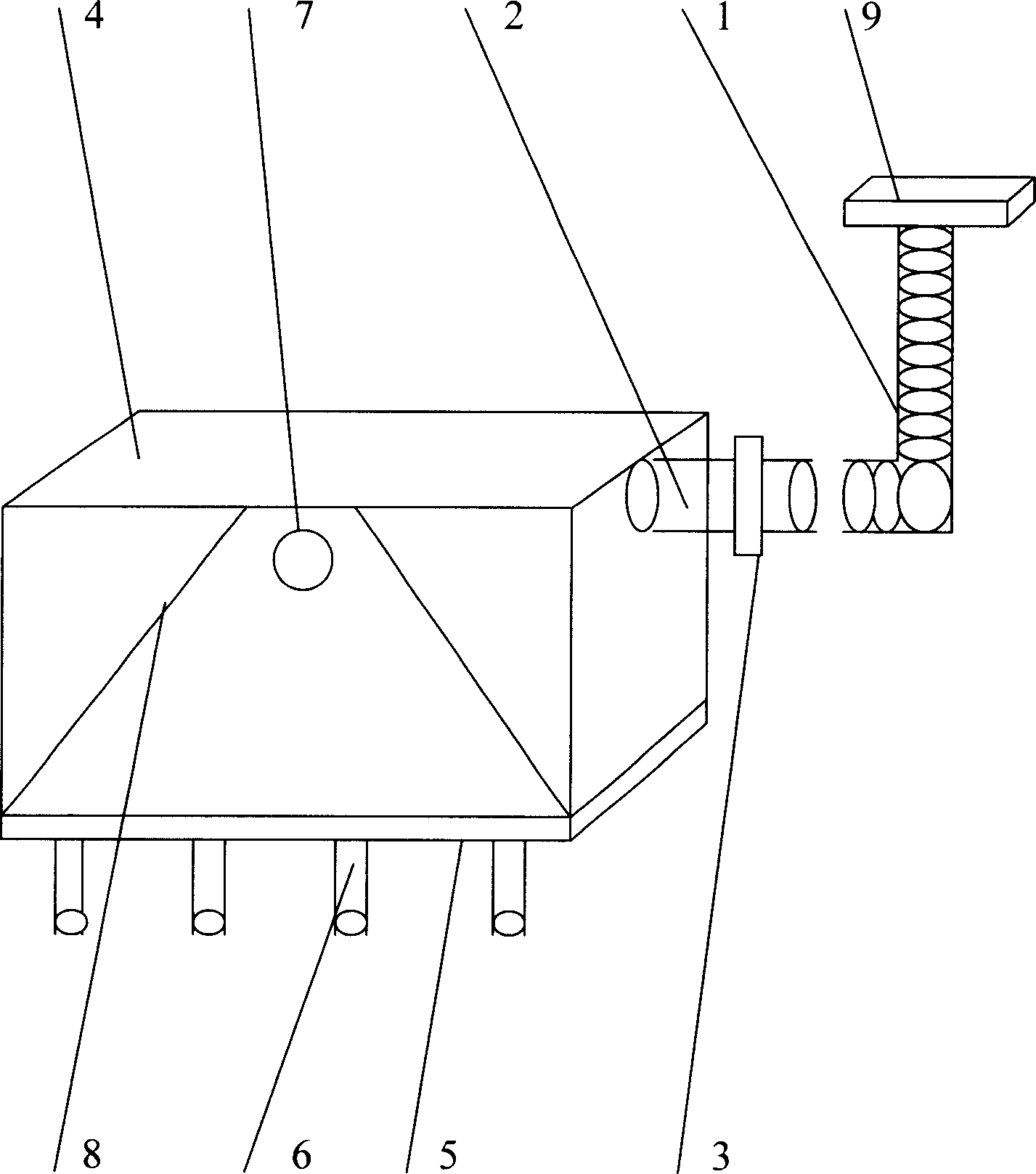

[0016] Referring to the accompanying drawings, the water inlet (2) and the water pipe clamp (3) are set on the upper side of the water tank (4) among the figures, and the viscose pad (5) provided at the bottom is connected with the outdoor unit of the air conditioner and the car radiator. The cover or the side cover is connected, and a diverter nozzle (6) is arranged at the bottom of the water tank (4). The upper part of the water tank (4) is provided with an overflow port (7) and a diversion groove (8). The condensed water in the water receiving tray (9) is guided into the water tank (4) through the drain pipe (1), the water inlet (2) and the water pipe card (3), and evenly distributed to the outside of the water tank (4) through the diverter nozzle, and the water tank (4) ) volume, size, the number and the caliber of the flow nozzle (6) are directly proportional to the power of the air conditioner when it is working.

[0017] The horizontal height of the setting position of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com