A process for recovering carbon monoxide and hydrogen from the dehydrogenation tail gas of methanol dehydrogenation synthesis methyl formate unit

A technology of methyl formate and carbon monoxide, which is applied in the chemical industry, can solve the problems of increased production cost of methyl formate and waste of hydrogen, and achieve the effects of reducing purification load, improving recovery efficiency, and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

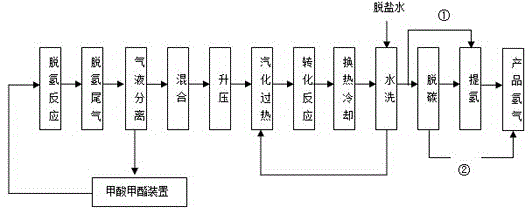

[0023] A process for recovering carbon monoxide and hydrogen from the dehydrogenation tail gas of the methanol dehydrogenation synthesis methyl formate unit. In this process, the recovery of the dehydrogenation tail gas from methanol dehydrogenation to methyl formate adopts steam reforming to produce hydrogen-membrane separation decarburization- The process method of hydrogen extraction by pressure swing adsorption.

[0024] The composition of the dehydrogenation tail gas from methanol dehydrogenation to methyl formate after gas-liquid separation is (v / v%): CO7.20%; CO 2 2.30%; CH 3 OCH 3 0.80%; CH 4 1.00%; H 2 88.70%. Gas volume is 2000Nm 3 / h, the gas pressure is 0.1MPa. Using Cu:Zn:Al (molar ratio) = 8:1:0.8:0.2 carbon monoxide steam reforming catalyst, the reaction temperature is 230°C, the pressure is 1.5MPa, and the reaction space velocity is 3000h -1 , add water vapor 8.0kmol / h, the molar ratio of carbon monoxide and water in the dehydrogenation tail gas is 1:1.2...

Embodiment 2

[0027] A process for recovering carbon monoxide and hydrogen from the dehydrogenation tail gas of a methanol dehydrogenation synthesis methyl formate unit. In this process, the recovery of the dehydrogenation tail gas from methanol dehydrogenation to methyl formate adopts steam reforming hydrogen production-pressure swing adsorption decarburization -The technological method of hydrogen extraction by pressure swing adsorption.

[0028] After gas-liquid separation, the composition of methanol dehydrogenation to methyl formate dehydrogenation tail gas is (v / v%): CO8.50%; CO 2 2.05%; CH 3 OCH 3 0.680%; CH 4 1.12%; H 2 87.65%. Gas volume is 3500Nm 3 / h, the gas pressure is 0.1MPa. Using Cu: Zn: Al (molar ratio) = 7:1.2:0.78:0.25 carbon monoxide steam reforming catalyst, the reaction temperature is 250°C, the pressure is 2.0MPa, and the reaction space velocity is 1200h -1 , adding 26.56kmol / h of water vapor, the molar ratio of carbon monoxide and water in the dehydrogenation ...

Embodiment 3

[0030] A process for recovering carbon monoxide and hydrogen from the dehydrogenation tail gas of a methanol dehydrogenation synthesis methyl formate unit. In this process, the recovery of the dehydrogenation tail gas from methanol dehydrogenation to methyl formate adopts steam reforming hydrogen production-pressure swing adsorption hydrogen extraction way of workmanship.

[0031] The composition of the dehydrogenation tail gas from methanol dehydrogenation to methyl formate after gas-liquid separation is (v / v%): CO6.20%; CO 2 2.00%; CH 3 OCH 3 0.65%; CH 4 0.80%;H 2 90.35%. Gas volume is 2000Nm 3 / h, the gas pressure is 0.1MPa. Using Cu:Zn:Al (molar ratio) = 8:1.5:0.75:0.25 carbon monoxide steam reforming catalyst, the reaction temperature is 245°C, the pressure is 1.8MPa, and the reaction space velocity is 2000h -1 , adding 20.76kmol / h of water vapor, the molar ratio of carbon monoxide and water in the dehydrogenation tail gas is 1:3.0, and the reformed gas volume afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com