Desulfurization synergist for calcium-based wet desulfurization, preparation and application method thereof

A technology of wet desulfurization and synergist, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problem that the stability of desulfurization synergist products affects the performance of desulfurization synergists, and the gypsum by-products that affect system stability Compositional purity, complex slurry components and other issues, to achieve the effect of improving the safety of use, increasing the scope of application, and reducing the number of openings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

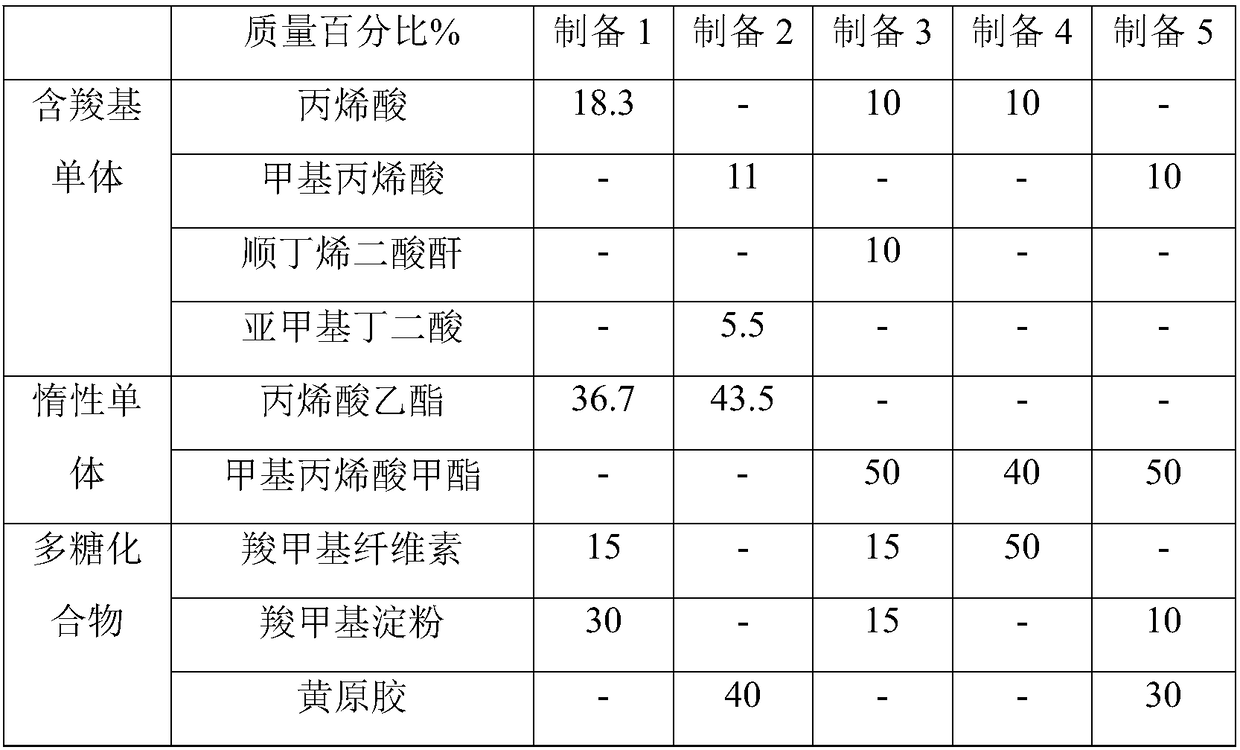

[0038] Preparation Example

[0039] The desulfurization synergist for calcium-based wet desulfurization of the present invention is prepared according to the following method, specifically comprising the following steps:

[0040] Step 1, prepare acrylic acid copolymer, specifically comprise the following steps:

[0041] Step A, replace the air in the airtight reactor with nitrogen;

[0042] Step B, under airtight conditions, add the isopropanol solution containing inert monomer and carboxyl-containing monomer;

[0043] Step C, under airtight conditions, add an isopropanol solution containing azobisisobutyronitrile; the amount of azobisisobutyronitrile is 0.5-1% of the total weight of the inert monomer and the carboxyl group-containing monomer;

[0044] Step D, keeping stirring the reaction solution, heating to 60°C, and polymerizing for 2-4 hours;

[0045] Step E, after the reaction is over, evaporate the isopropanol, and raise the temperature of the polymerized product to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com