Method for correcting common-mode wavefront sensor calibration in adaptive optical system

A technology of wavefront sensor and adaptive optics, which is applied in the field of calibration, can solve the problems of cumbersome process, cost, and high cost, and achieve the effect of avoiding time waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

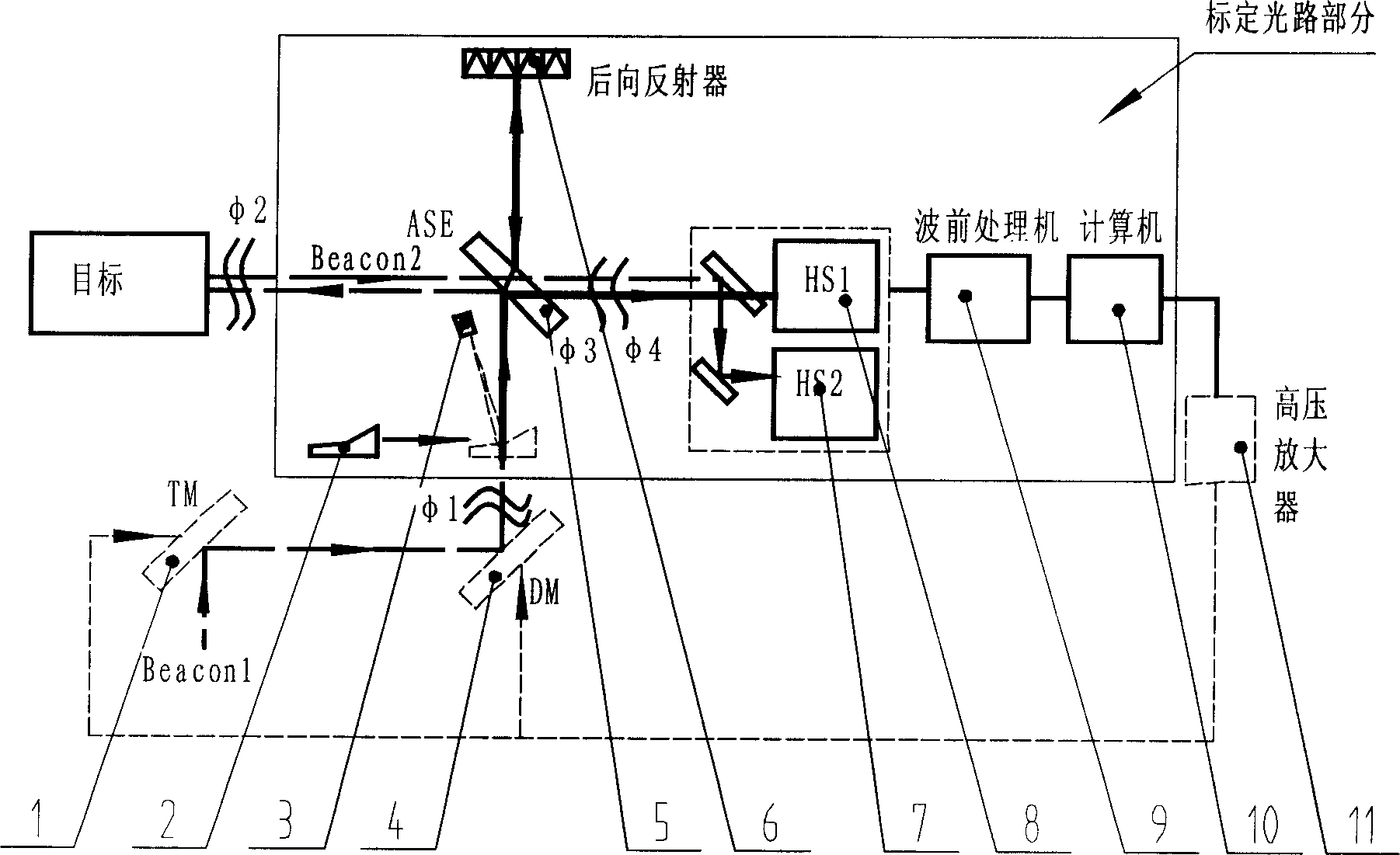

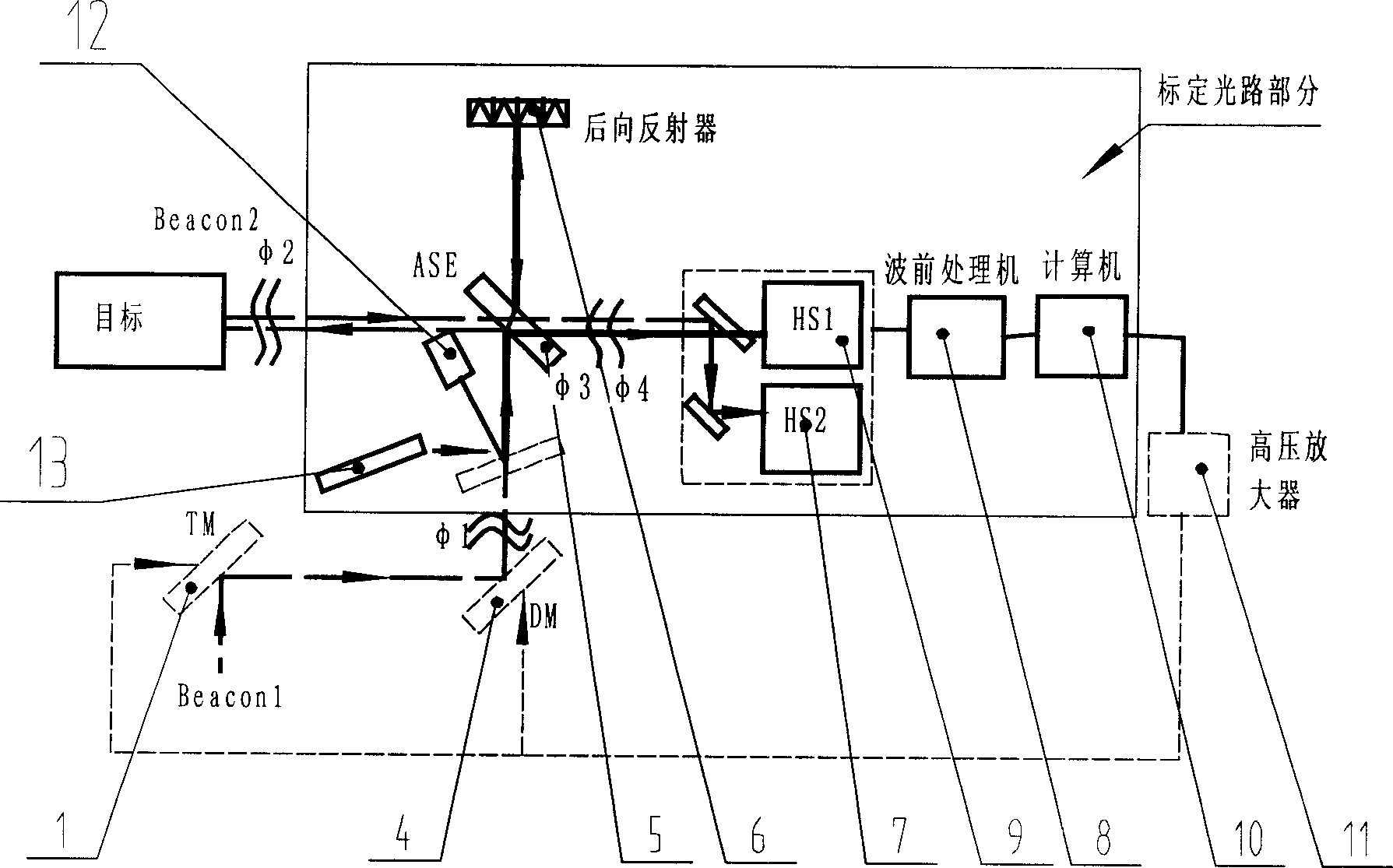

[0013] Such as figure 1 As shown, the system-wide aberration correction adaptive optics system used in the present invention includes a main laser beacon Beacon1, a tilting mirror TM1, a deformable mirror DM4, a common aperture beam splitter 5, and retroreflective devices 6, 7 and 8. Common mode wavefront detector, wavefront processor 9, computer 10, high voltage amplifier 11, atmospheric beacon Beacon2. The method for calibrating a common-mode wavefront sensor described in Technical Embodiment 1 of the present invention is shown in a thin solid line frame, including an off-axis parabolic mirror 2, a calibrating laser 3, a common-aperture beam splitter 5, and retroreflective devices 6, 7, and 8 Composed of a common-mode wavefront detector, a wavefront processor 9, and a computer 10, the light beam emitted by the calibration laser 3 is amplified by the microscope objective lens, and then collimated into parallel light by the introduced off-axis parabolic mirror 2, and the paral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com