Cotton candy machine

A technology of marshmallow and syrup, applied in confectionery, confectionary industry, food science, etc., can solve the problems of complicated preparation work, limitation of opening area, limitation of rotating pot volume, etc., and achieve the effect of easy operation and improved workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

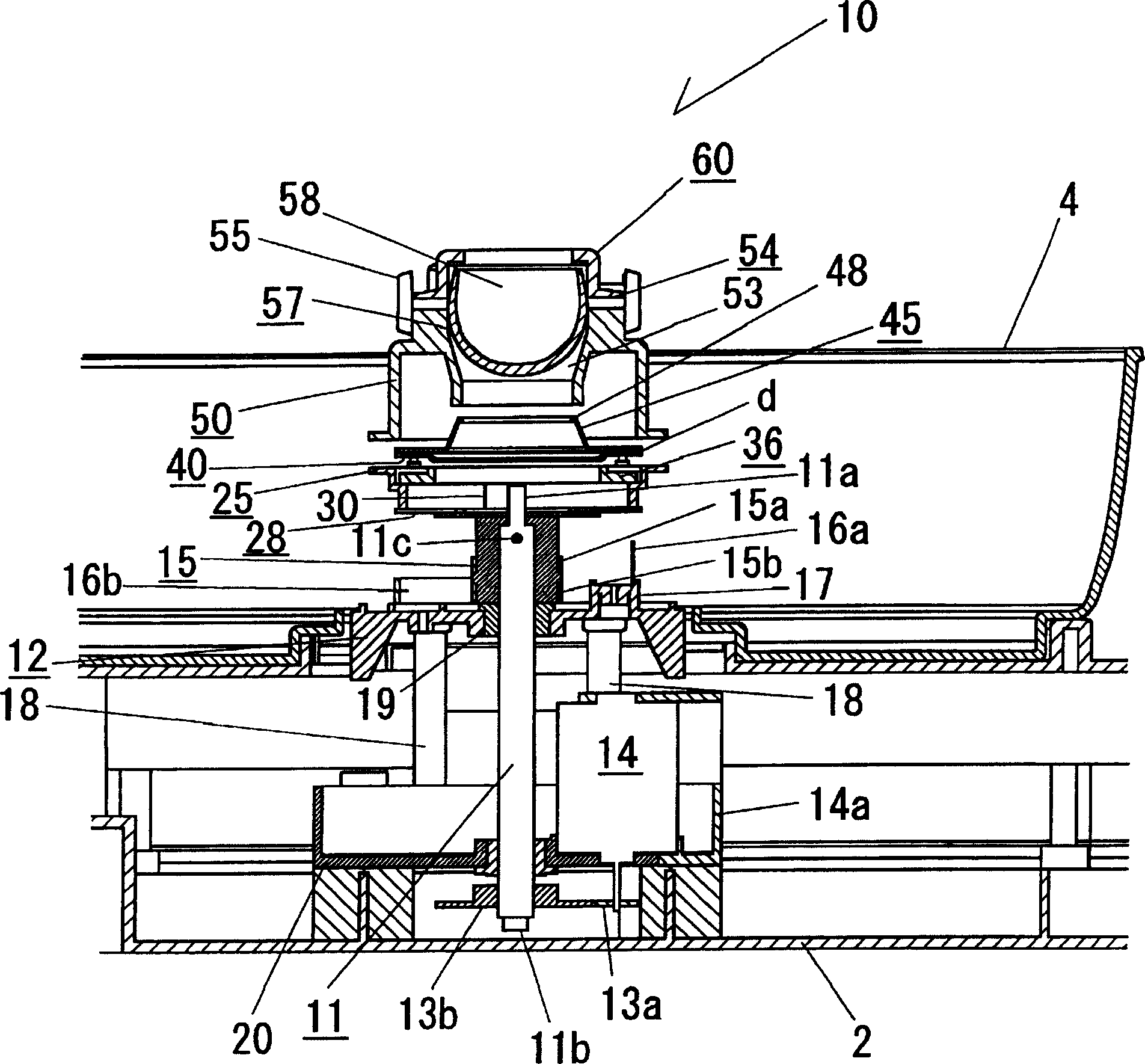

[0029] Hereinafter, Embodiment 1 of the cotton candy machine of the present invention will be described with reference to the drawings.

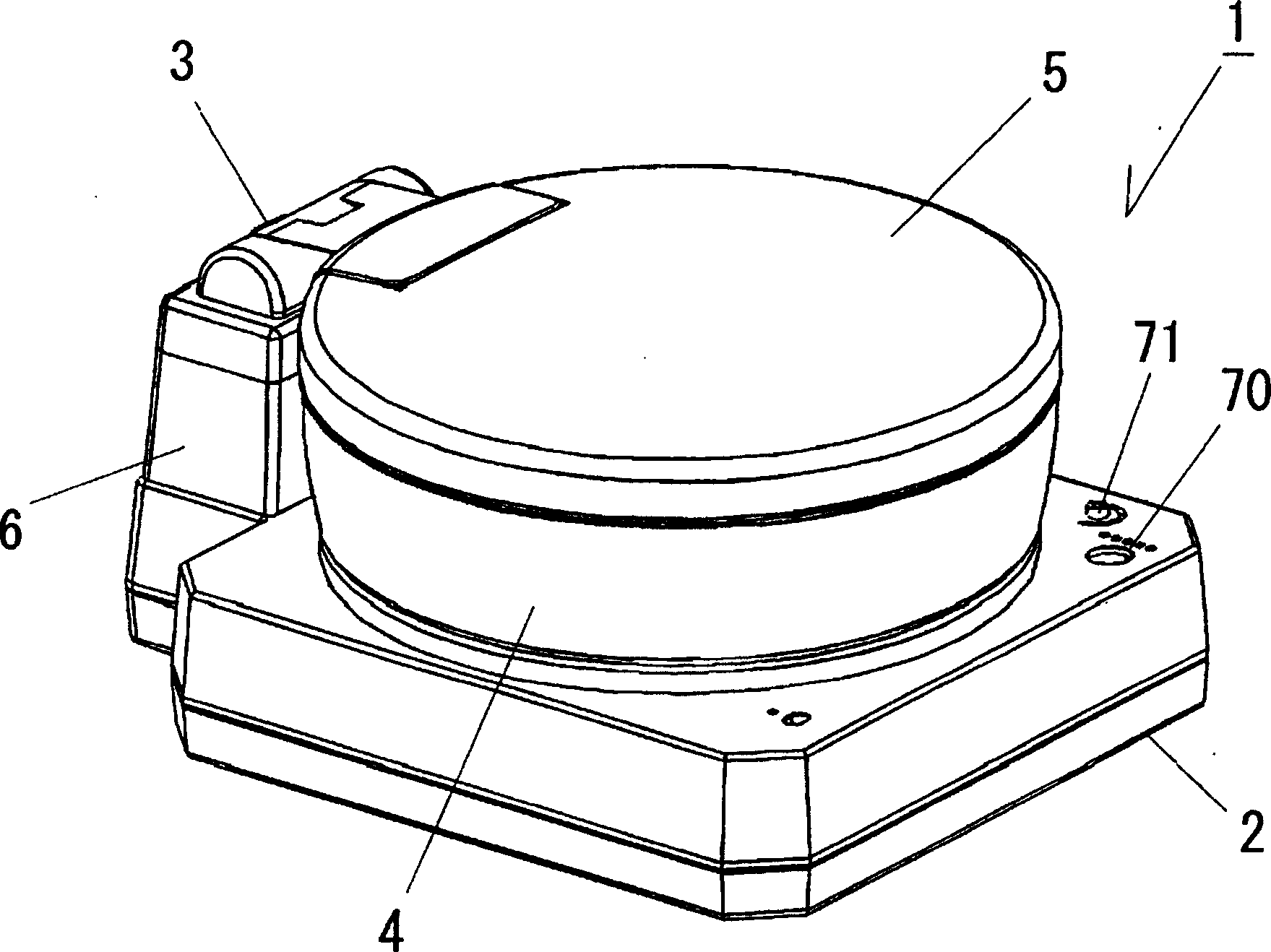

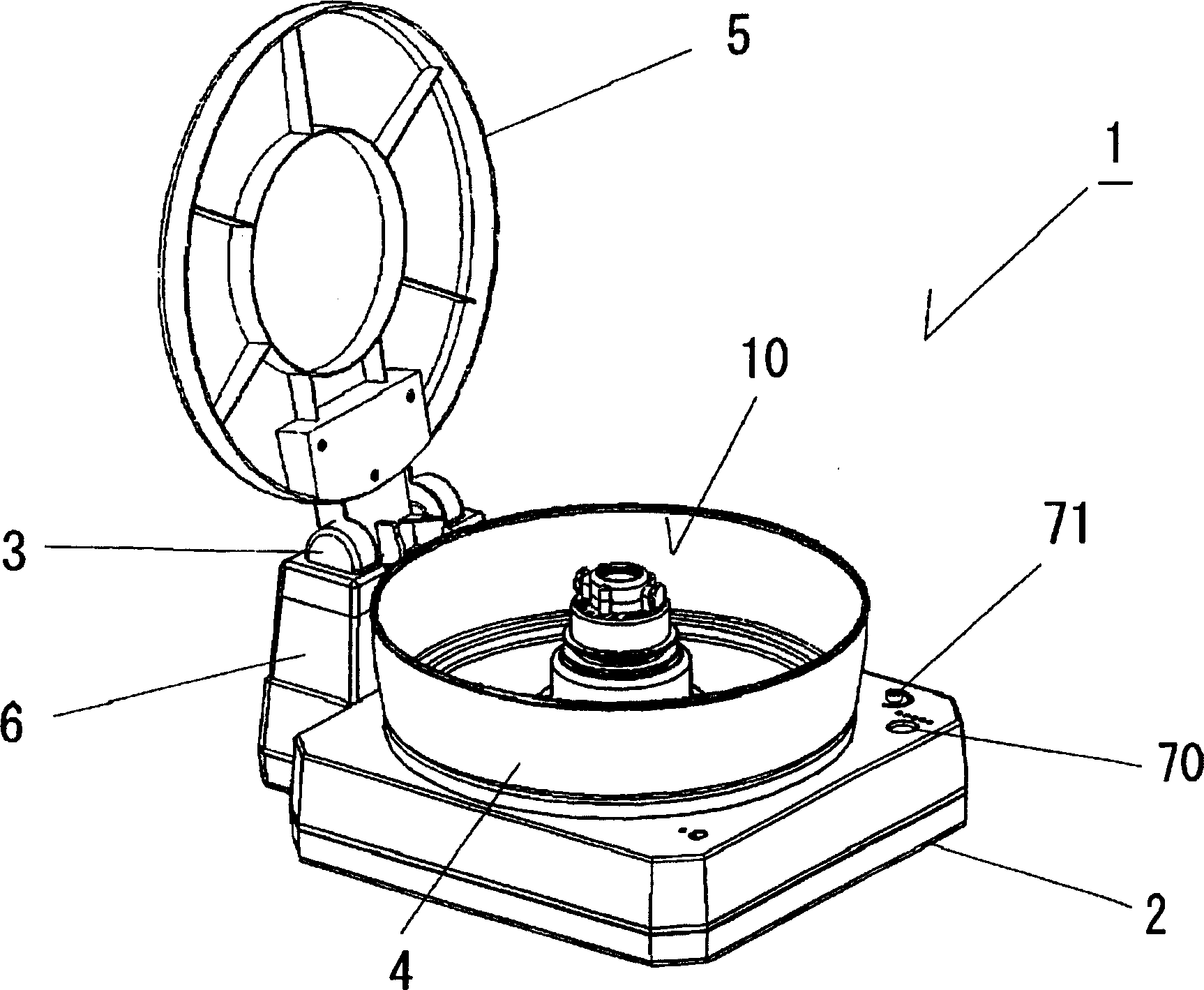

[0030] like figure 1 , figure 2 As shown, the cotton candy machine 1, the cotton candy production part 10 has a base 2 arranged in the center, and an annular tray 4 installed around the cotton candy production part 10 on the base 2. In this configuration, thread-like syrup is scattered outward from the cotton candy manufacturing unit 10, and the syrup can be wound up in the tray 4 with disposable chopsticks or the like.

[0031] Furthermore, a support portion 6 including a hinge member 3 is connected to the left side of the base 2 . Furthermore, a disk-shaped cover 5 is connected to this hinge member 3 . Then, by the hinge member 3, by making the disc-shaped cover 5 fall substantially horizontally, or stand up substantially vertically, the cotton candy machine 1 becomes the covered state in which the inside of the tray 4 is covered (refe...

Embodiment 2

[0064] The marshmallow manufacturing unit 10a having a configuration different from the above will be described. In addition, the same symbols are assigned to the same configuration as in the first embodiment, and the description thereof will be simplified or omitted.

[0065] like Figure 7 , Figure 8 As shown, in Embodiment 2, the winding reel placement table 85 , the winding reel 36 , the melting tray 40 , the cover 45 , and the protective case 95 are also mounted on the horizontal base 28 . However, in this embodiment, the mechanism for fixing the position of these components on the horizontal base 28 is different from that of the first embodiment. Hereinafter, this mechanism will be described.

[0066] like Figure 8 As shown, the reel placement platform 85 has an open ring shape in its center, and a section 90 is provided on its inner surface. In addition, three supporting parts 86 that pivotally support claws 87 to be described later are provided around the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com