Three-dimensional curved surface covering forming method and die for streamline locomotive cab

A locomotive driver, three-dimensional curved surface technology, applied in the direction of manufacturing tools, copying process control systems, metal processing equipment, etc., can solve the problems of inconvenient profiling, inconvenient observation of skin and wooden formwork, etc., to reduce labor Strength, considerable economic benefits, and the effect of improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

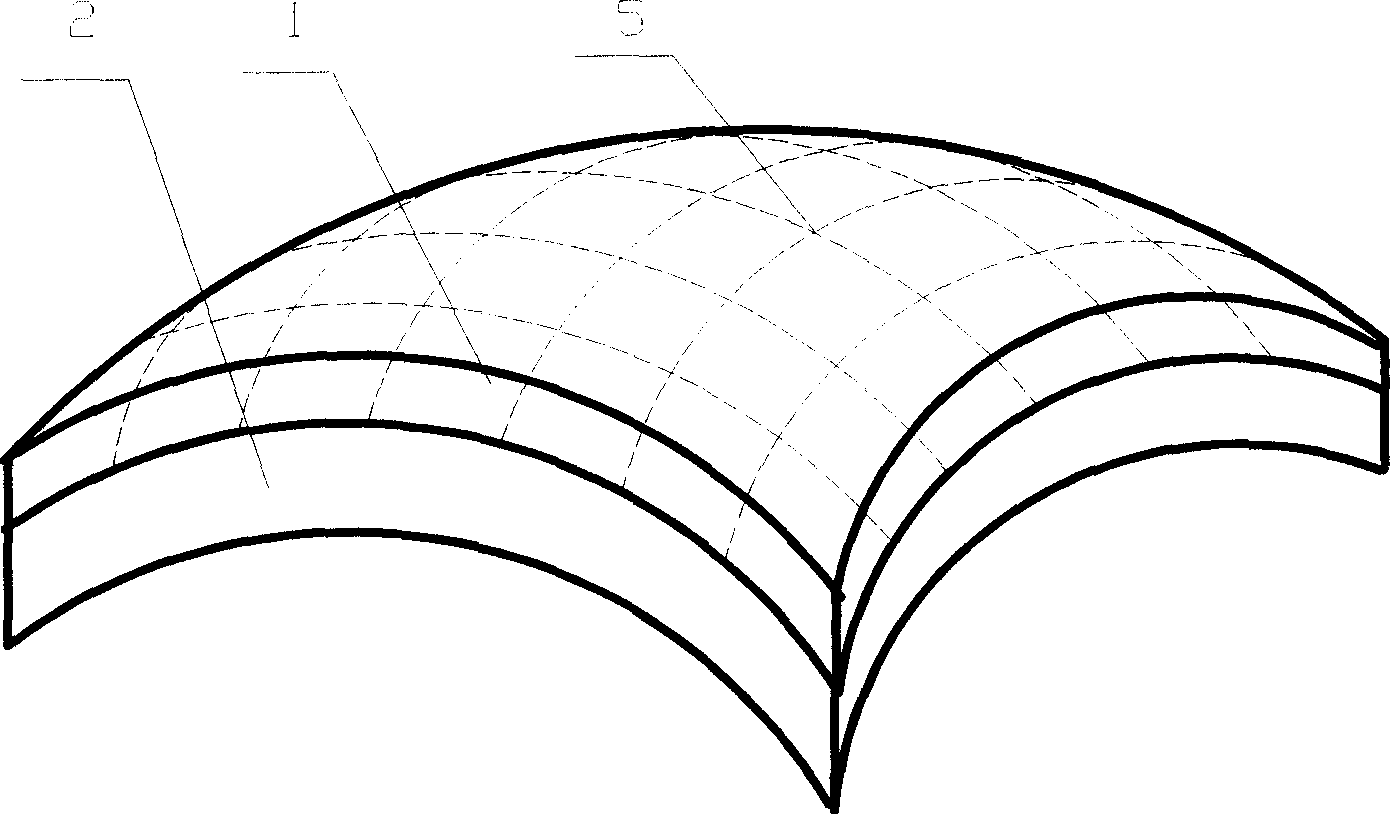

[0014] The accompanying drawing shows a schematic structural diagram of an embodiment of the present invention, and the present invention will be further described below in conjunction with the accompanying drawings and the embodiment.

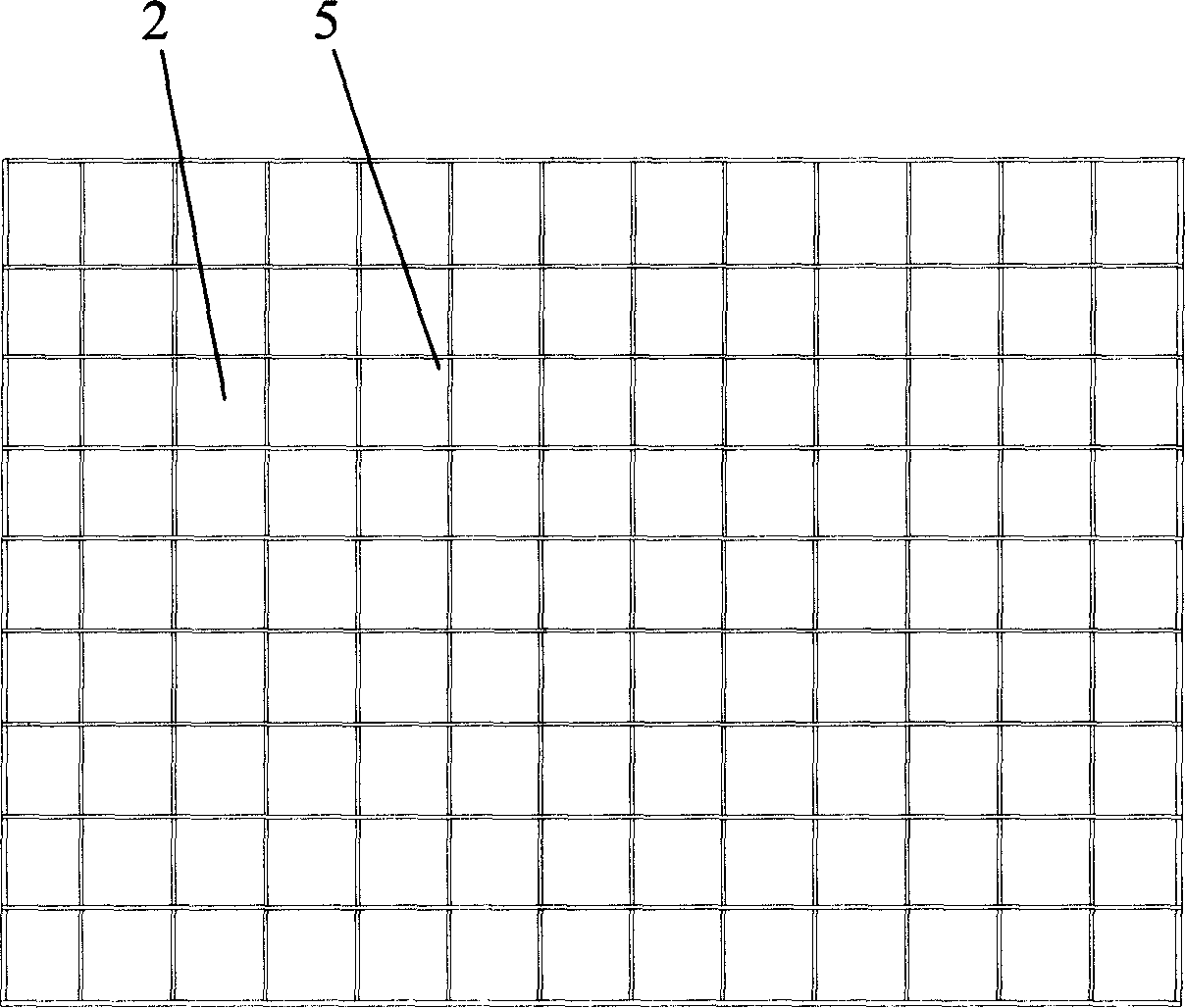

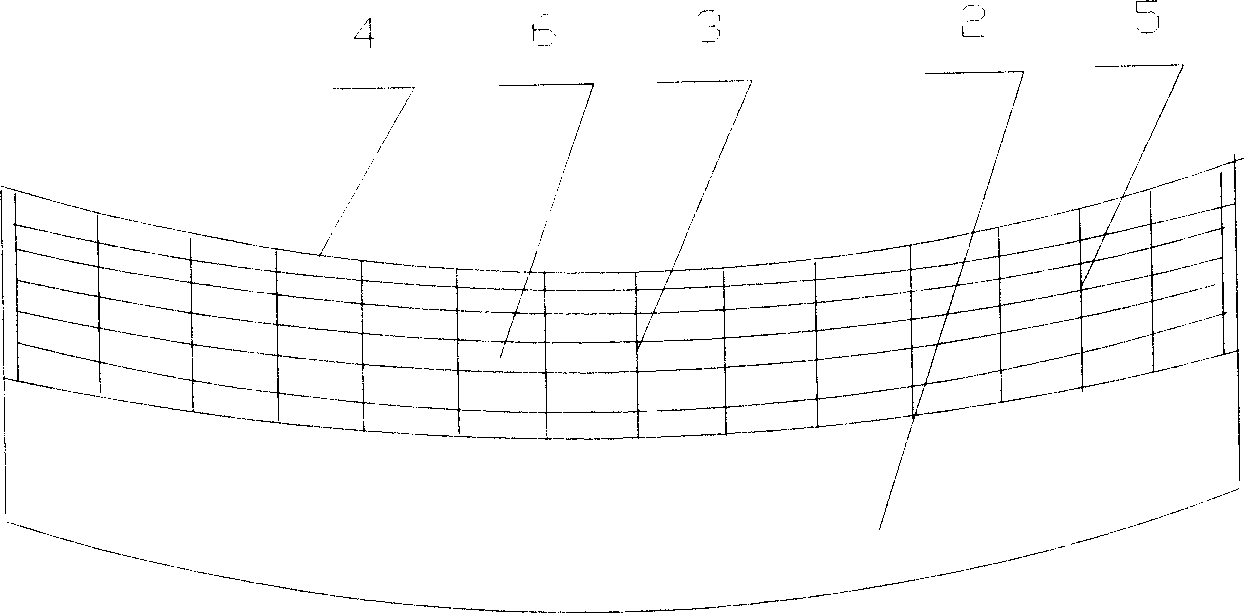

[0015] As can be seen from the accompanying drawings, the present invention is a streamlined locomotive cab skin, which adopts the block production method of the streamlined locomotive cab skin. One-to-one correspondence of the combined steel mold model, and through the grid holes of the combined steel mold to observe the bonding between the skin and the steel mold from the back of the steel mold to judge the forming degree of the skin; the combined steel mold is a grid plate The visible structure of the beam and the convex surface of the diaphragm of the composite steel mold grid are cut and formed by the laser cutting machine according to the electronic data of the curved surface of the inner surface of the skin. The visual structure of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com