Method for fabricating LED illumination light source and LED illumination light source

一种LED照明、制造方法的技术,应用在白色LED照明光源领域,能够解决无法抑制LED照明光源色斑等问题,达到防止色斑、减轻色斑的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

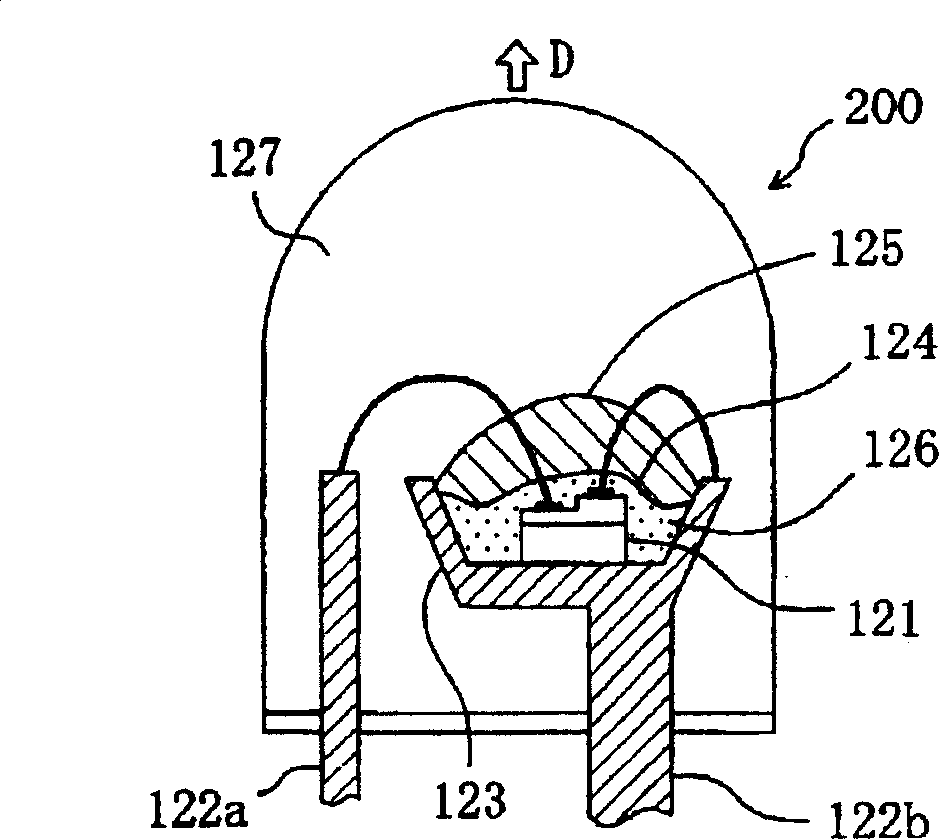

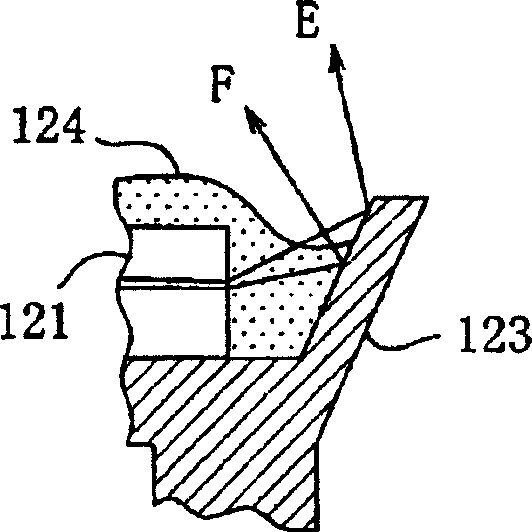

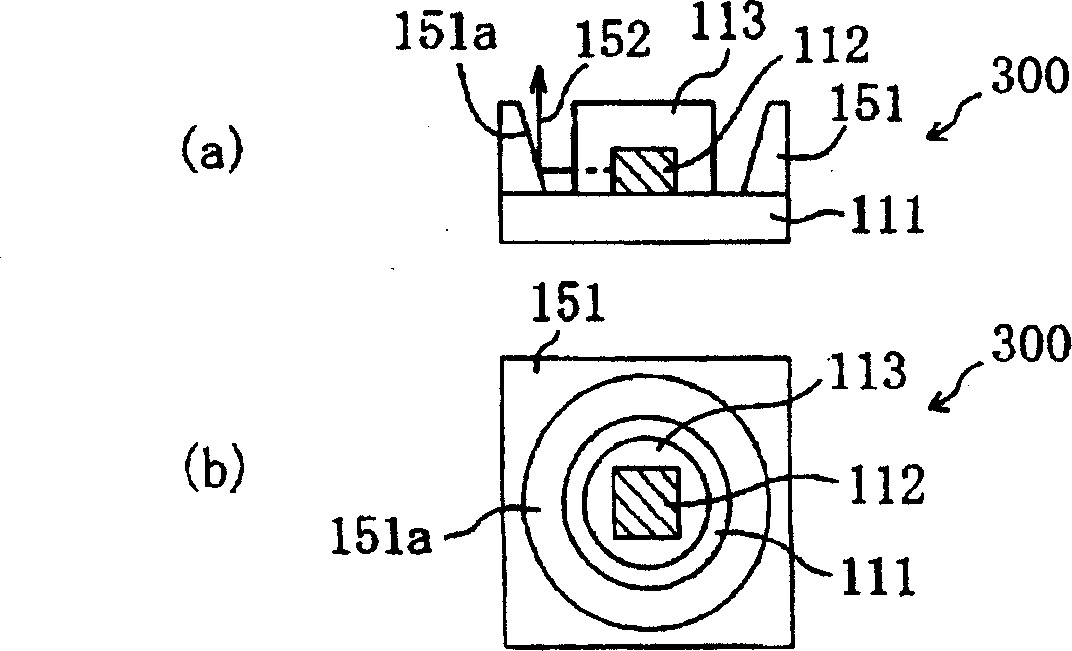

[0076] The inventors of the present application considered reducing the color unevenness by scattering the light (yellowish white) emitted obliquely upward from the LED chip and mixing it with other white light in order to suppress the color unevenness of the LED lighting source. If the method of forming the structure for generating such scattering is too complicated, the mass production of the LED lighting source will be reduced and the cost will be increased. Therefore, it is desirable to suppress stains with a structure as simple as possible. The inventors of the present application found that color unevenness can be significantly reduced by covering the phosphor resin portion with a translucent resin portion (light diffusion layer) in which a diffusing agent (fine particles) is dispersed, and completed the present invention.

[0077]The LED illumination light source of the present invention includes at least one LED chip mounted on a substrate, a phosphor resin portion cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com