Wound internal rotor of double mechanical port electric machine

A dual mechanical port, winding type technology, applied in the manufacture of stator/rotor body, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problem of poor heat dissipation effect, easy deformation of rotor winding ends, etc. problem, to achieve the effect of eliminating the problem of phase-to-phase insulation, small deformation, and ensuring symmetry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

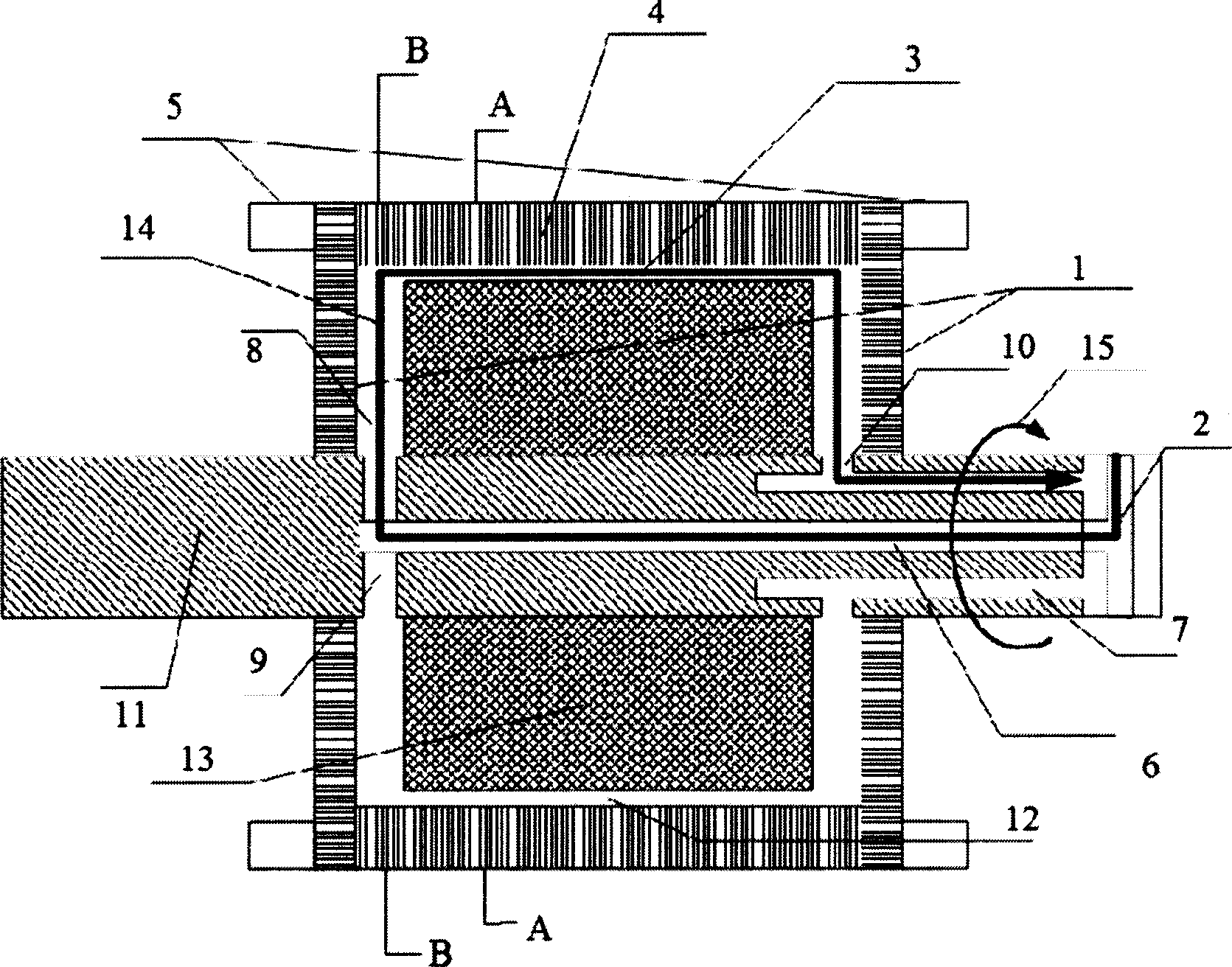

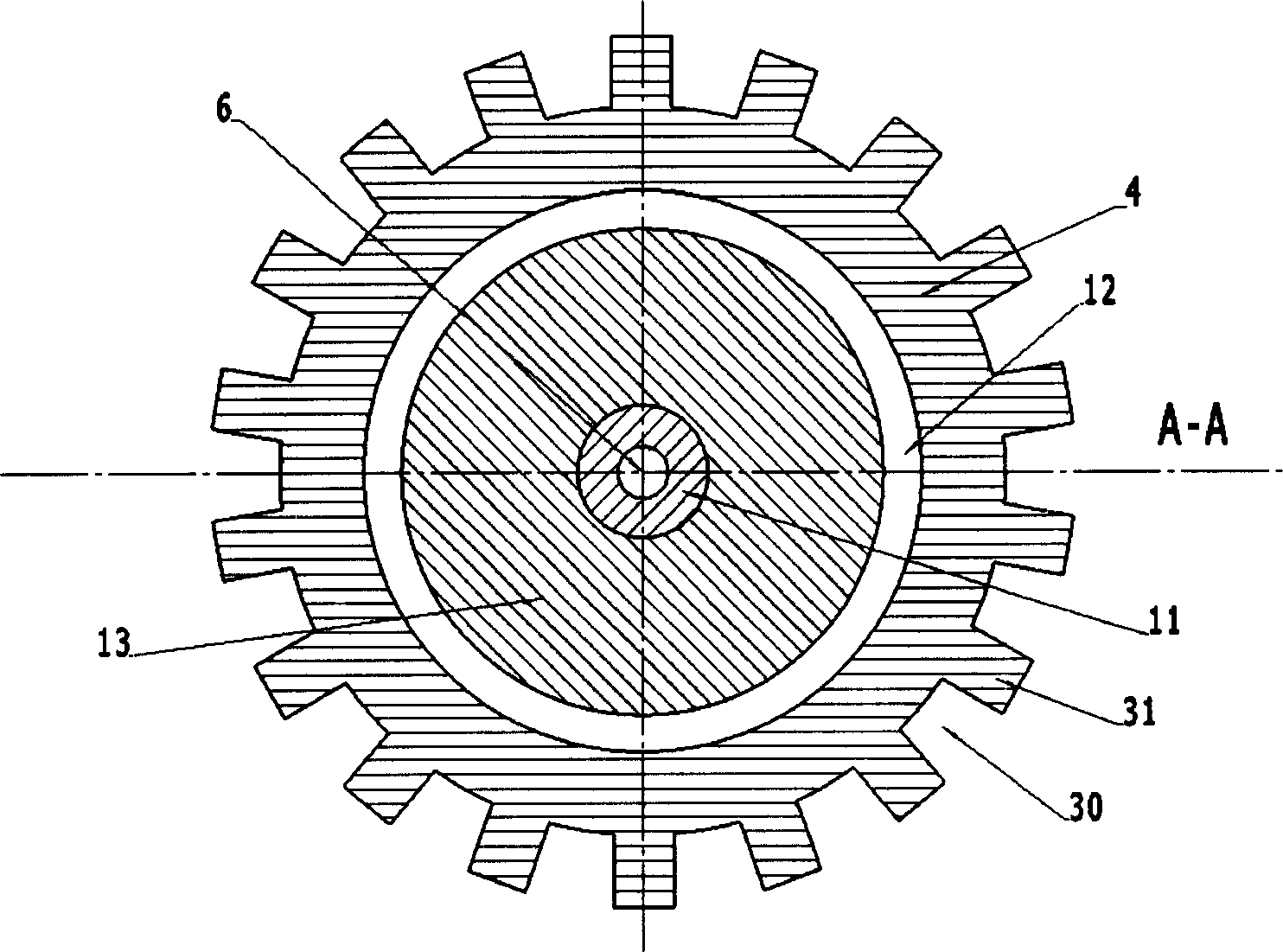

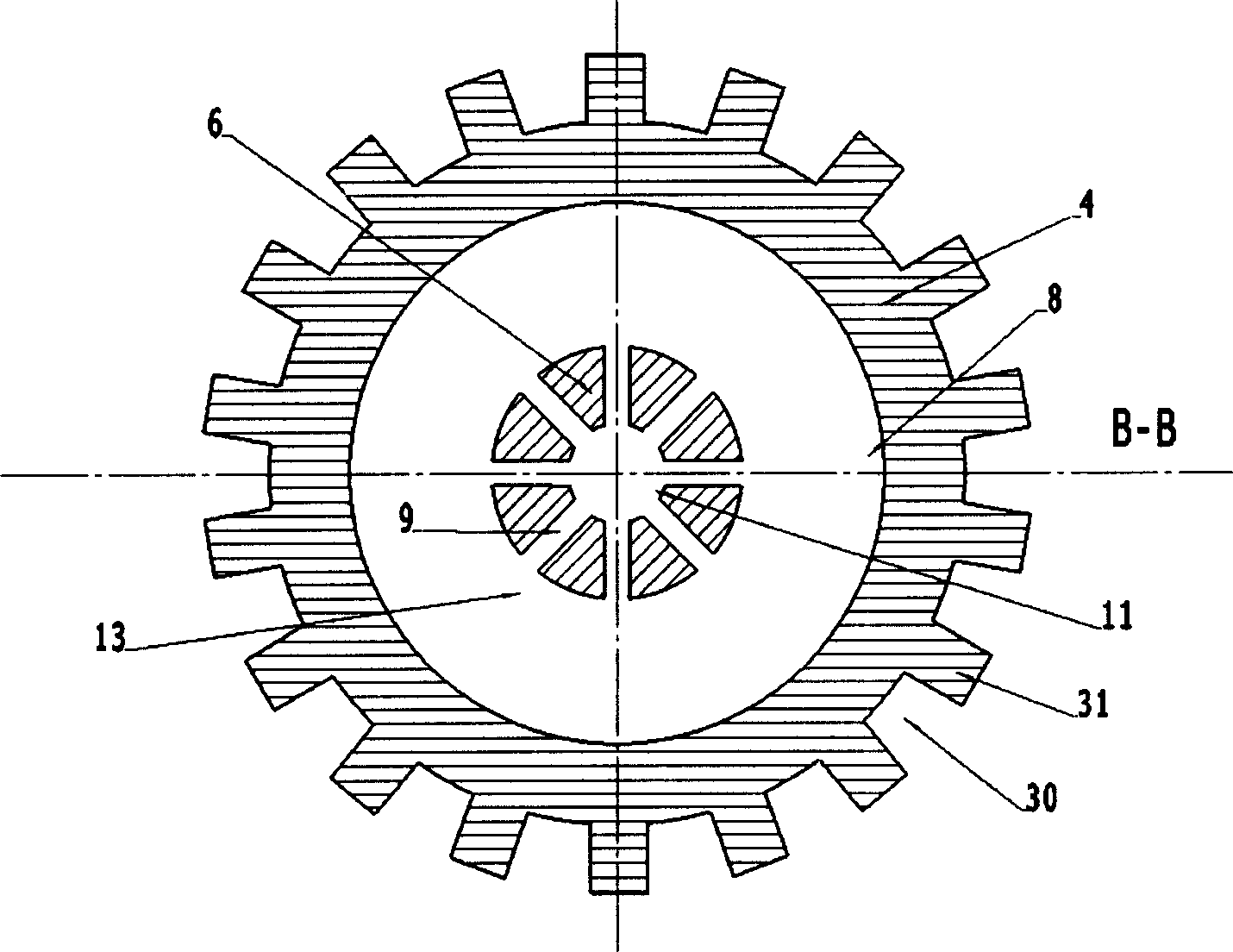

[0022] Inner rotor structure of the present invention such as figure 1 shown. The 2nd, dynamic sealing device, this dynamic sealing device has the rubber sealing ring that prevents coolant from overflowing, is the key component that guarantees cooling fluid to pass to rotating part effectively from static part, 11, rotor double-layer hollow shaft. In the double-layer hollow shaft 11, there is a long blind hole concentric with the double-layer hollow shaft 11—the inner shaft hole 6, which is driven into the end of the shaft to form an inner hollow structure. This layer of hollow structure is the input axial passage of the coolant, and its main function is to pass the coolant from the outside into the inside of the rotor. Because it is far away from the heat source, that is, the radial distance of the winding, it is not the main part for heat exchange and rotor heat dissipation. At the position near the blind end of the inner shaft hole 6, several radial through holes 9 are di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com