Chain transmission or steering device and the chain or chain wheel used therein

A steering gear, chain drive technology, applied in the direction of belt/chain/gear, drag chain, hanging chain, etc., to avoid line contact, increase the risk of damage to the chain or sprocket, and the effect of large chain traction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

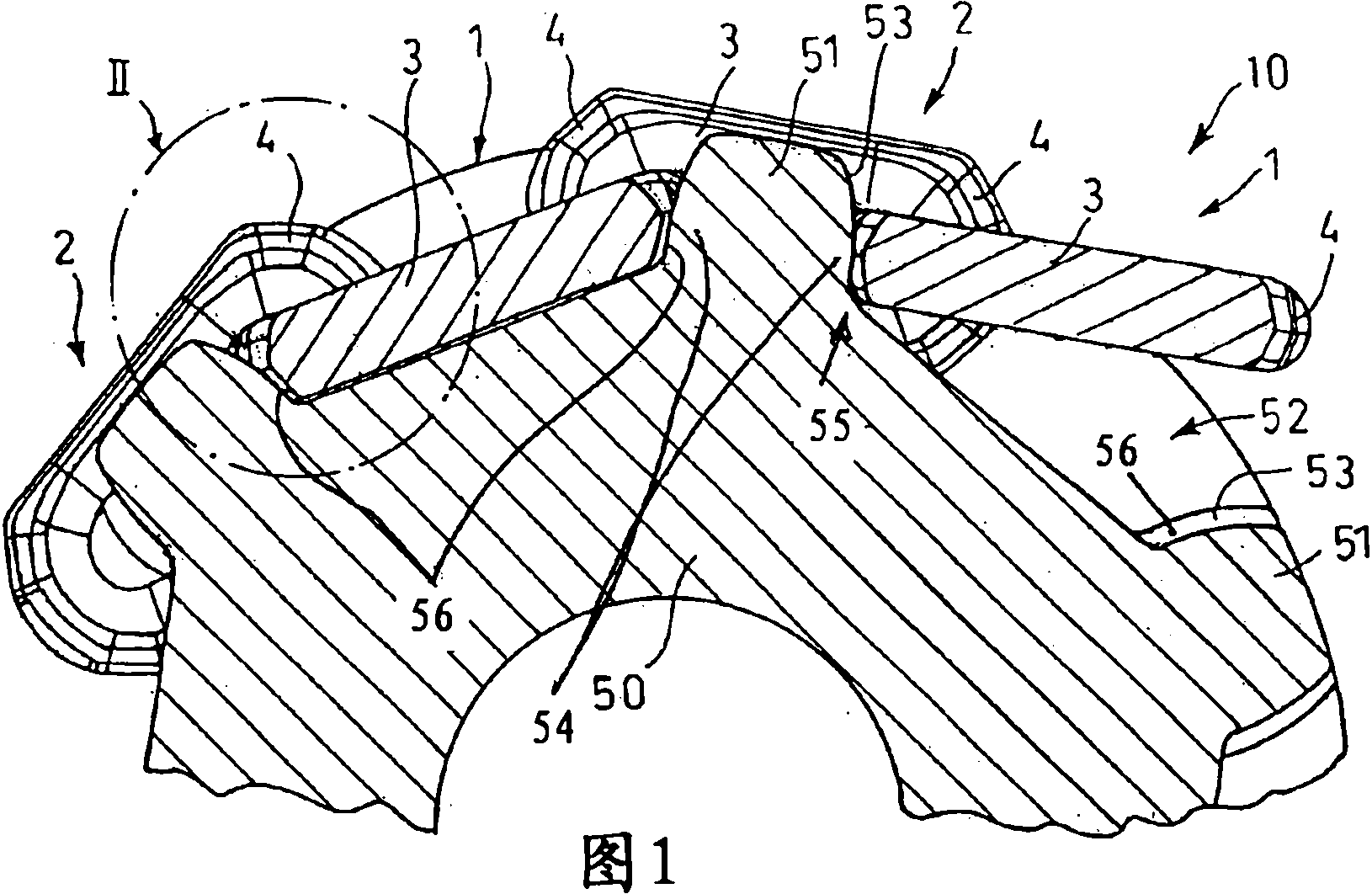

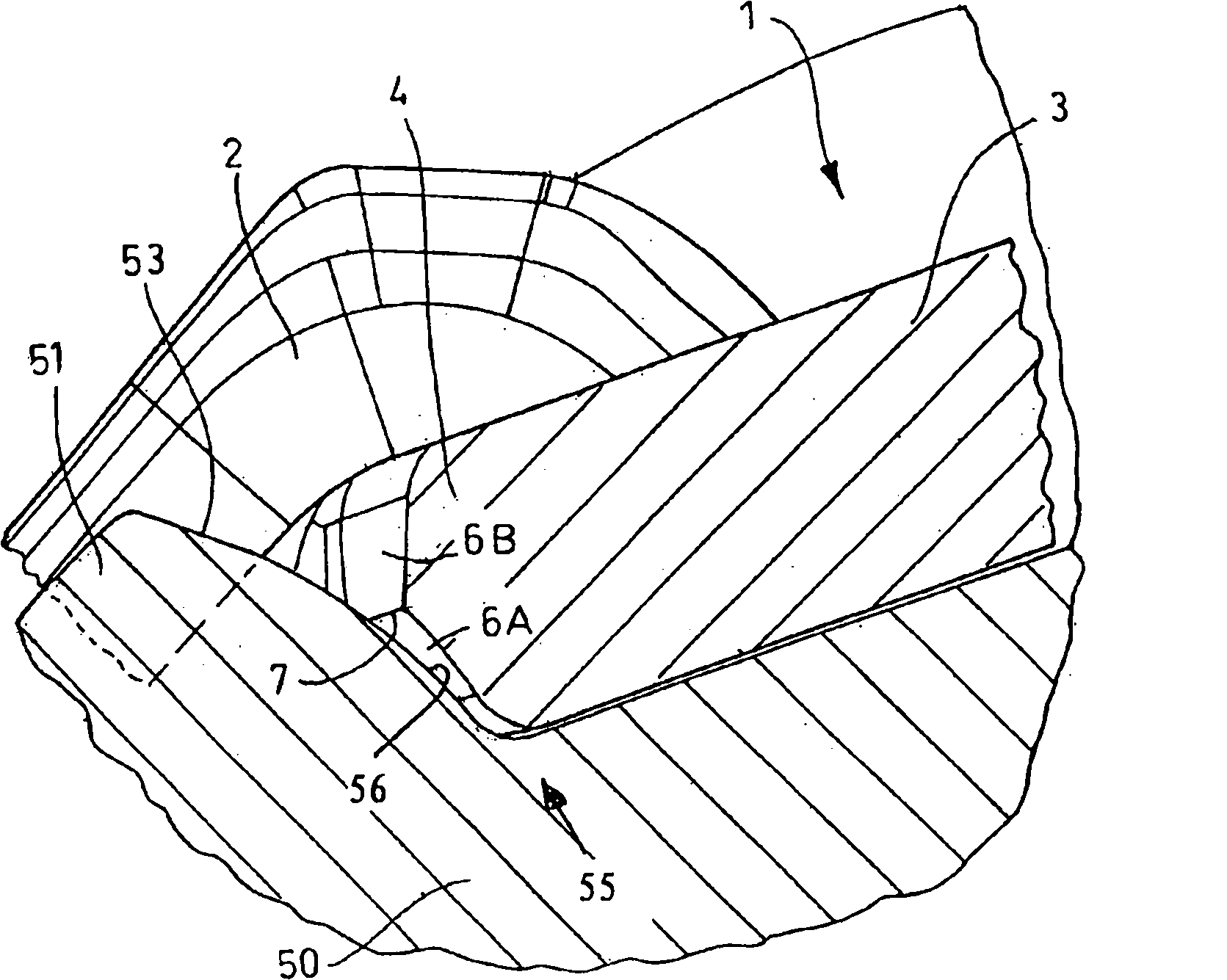

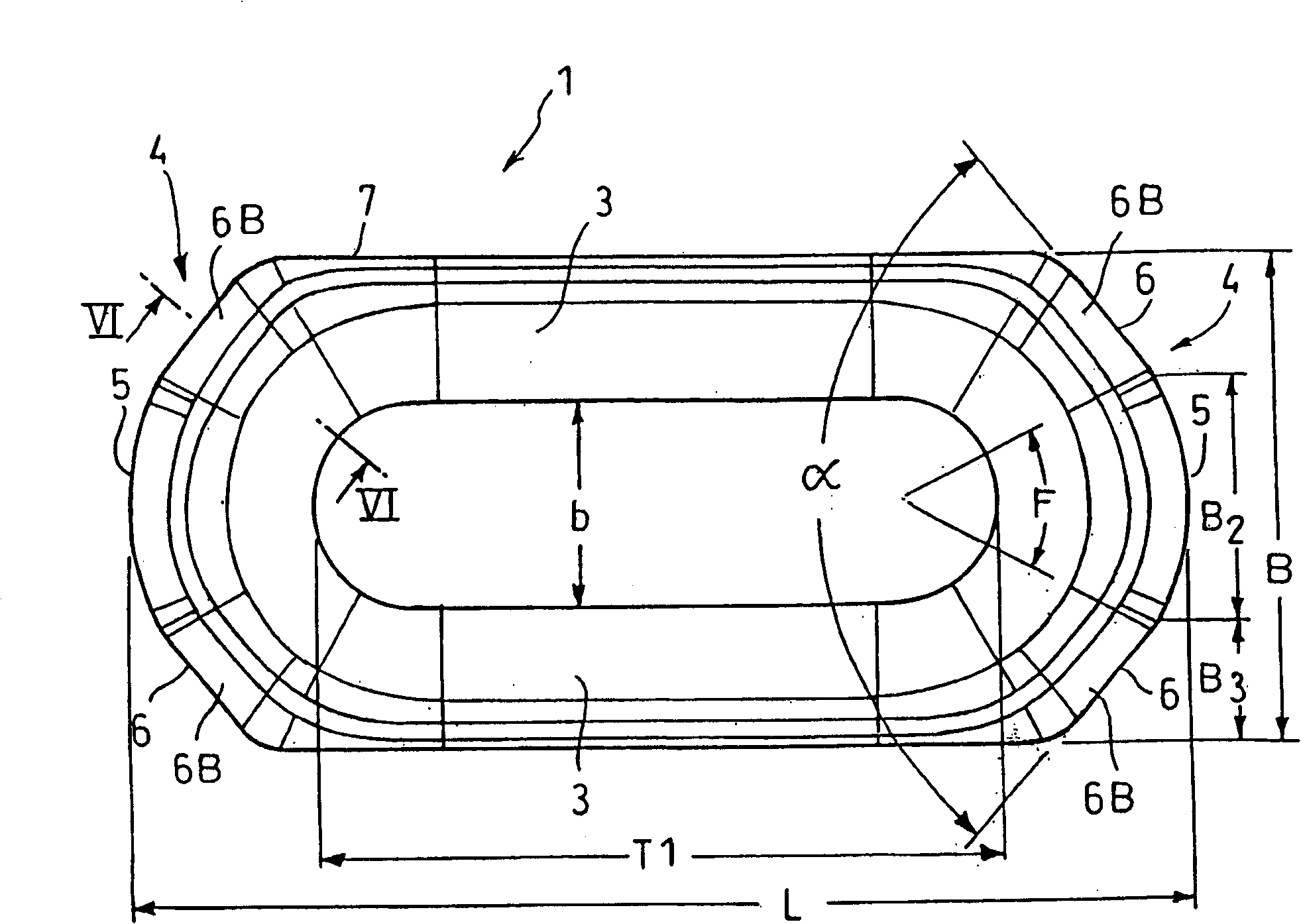

[0025] figure 1Shown are two horizontal links 1 and two vertical links 2 connected to them in a plow chain generally indicated by reference numeral 10, which are designed identically to each other in the illustrated embodiment, And as a die forging, it is composed of two chain link edges 3 parallel to each other and the chain head 4 that connects them and is designed as an arrowhead at the top of the horizontal link 1 and the vertical link 2. exist figure 1 with 2 Shown is the plow chain 10 meshing with the sprocket teeth 51 of a sprocket 50, which is selectively driven in one or the other direction of rotation by means of a drive (not shown further) during operation of the underground plowing plant. The sprocket 50 is provided with chainring pockets 52 between two adjacent sprocket teeth 51 , which are delimited by tooth flanks 53 of the teeth 51 . Here, the device is designed in such a way that the tooth flanks 53 delimiting the chain ring socket 52 are provided with sphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com