Component feeder

A technology for supplying devices and components, applied in the direction of electrical components, electrical components, delivery objects, etc., which can solve the problems of reducing the pasting area, bumps and bumps, and the covering tape cannot be easily discharged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

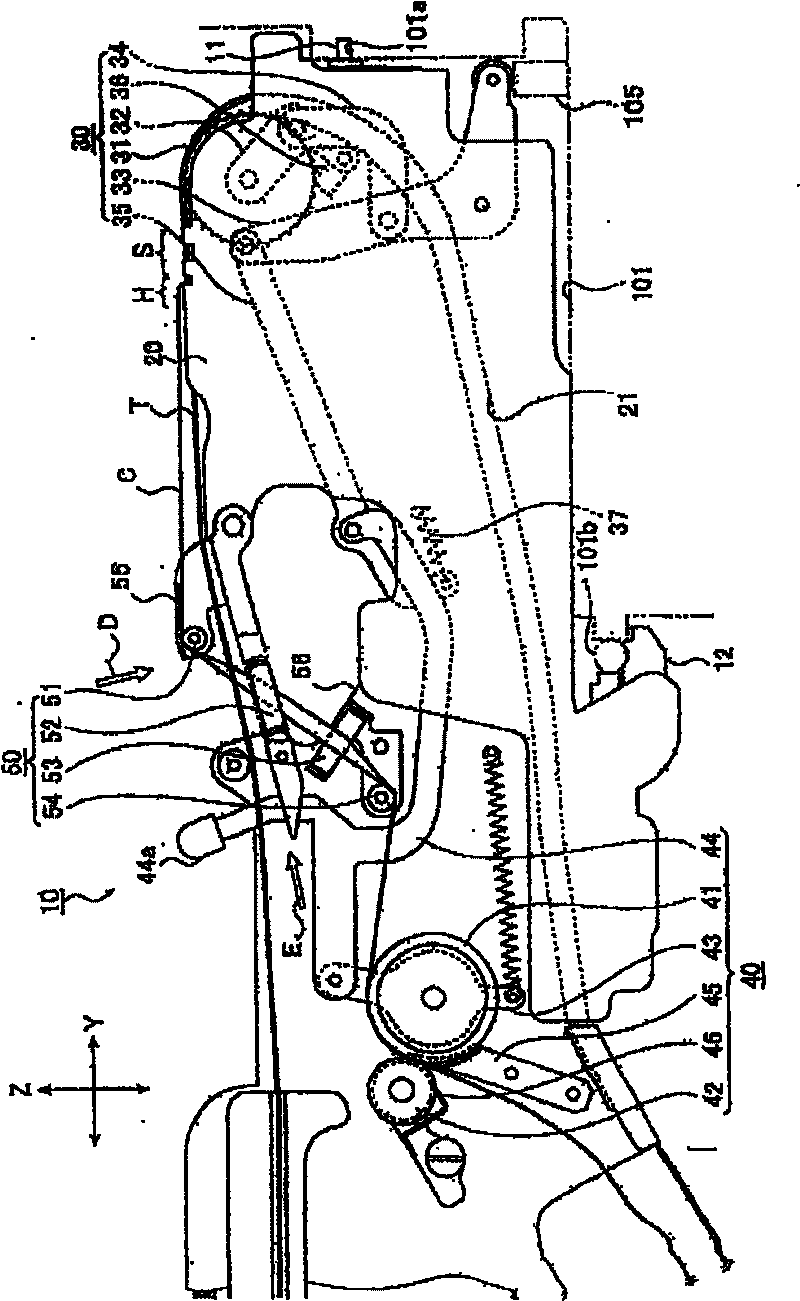

[0026] figure 1 It is a schematic side view showing a part of a parts feeder (parts supplying device) according to one embodiment of the present invention.

[0027] The components feeder 10 of this embodiment is mounted on the above-mentioned feeder magazine by inserting the engaging protrusion 11 into the engaging hole of the feeder magazine provided by the electronic component mounting device (not shown), and is similarly A plurality of parts feeders 10 are installed and used in parallel. figure 1 A part of the front end side of the components feeder 10 mounted on the feeder magazine is shown.

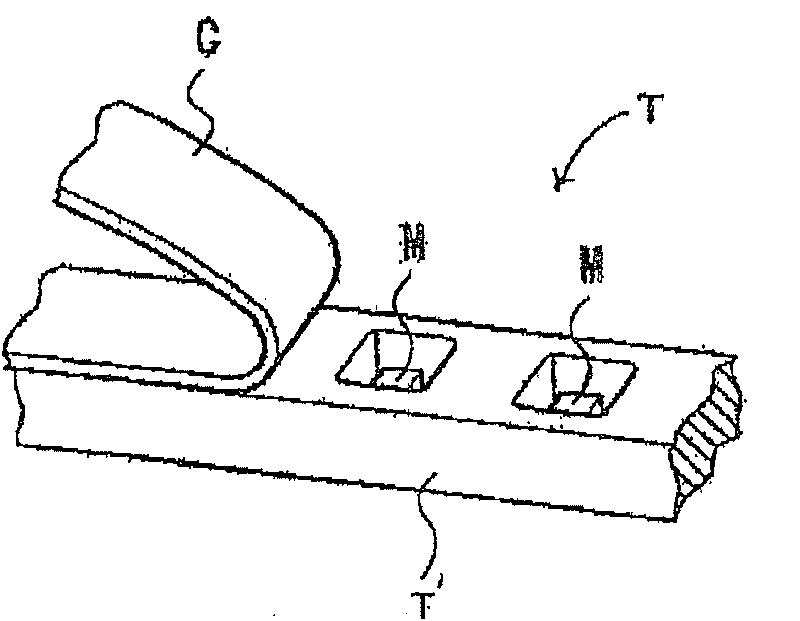

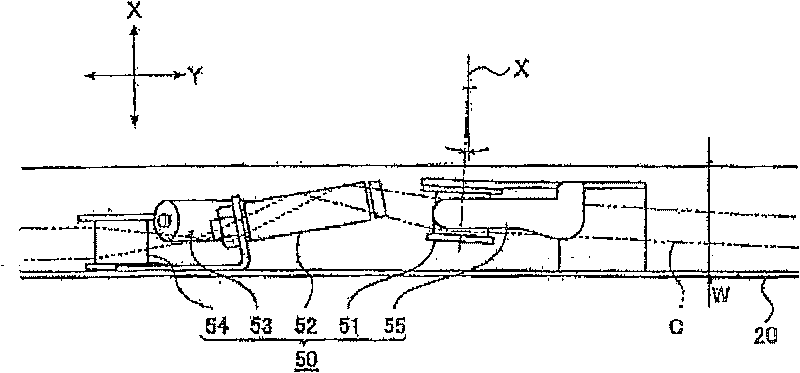

[0028] The parts feeder 10 sequentially feeds out the carrier tape T preliminarily wound on the reel from a reel (not shown) held on the rear end side, and moves toward the front end side along the transport path 21 formed on the frame body 20 . to deliver. Such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com