Construction method for tunnel contact passage in shield section of underground railway

A communication channel and interval tunnel technology, which is applied in the construction field of the subway shield interval tunnel communication channel, can solve the problems of high construction cost, large frost heaving and thawing, and adverse effects of the surrounding environment, so as to reduce the construction cost and shorten the construction period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

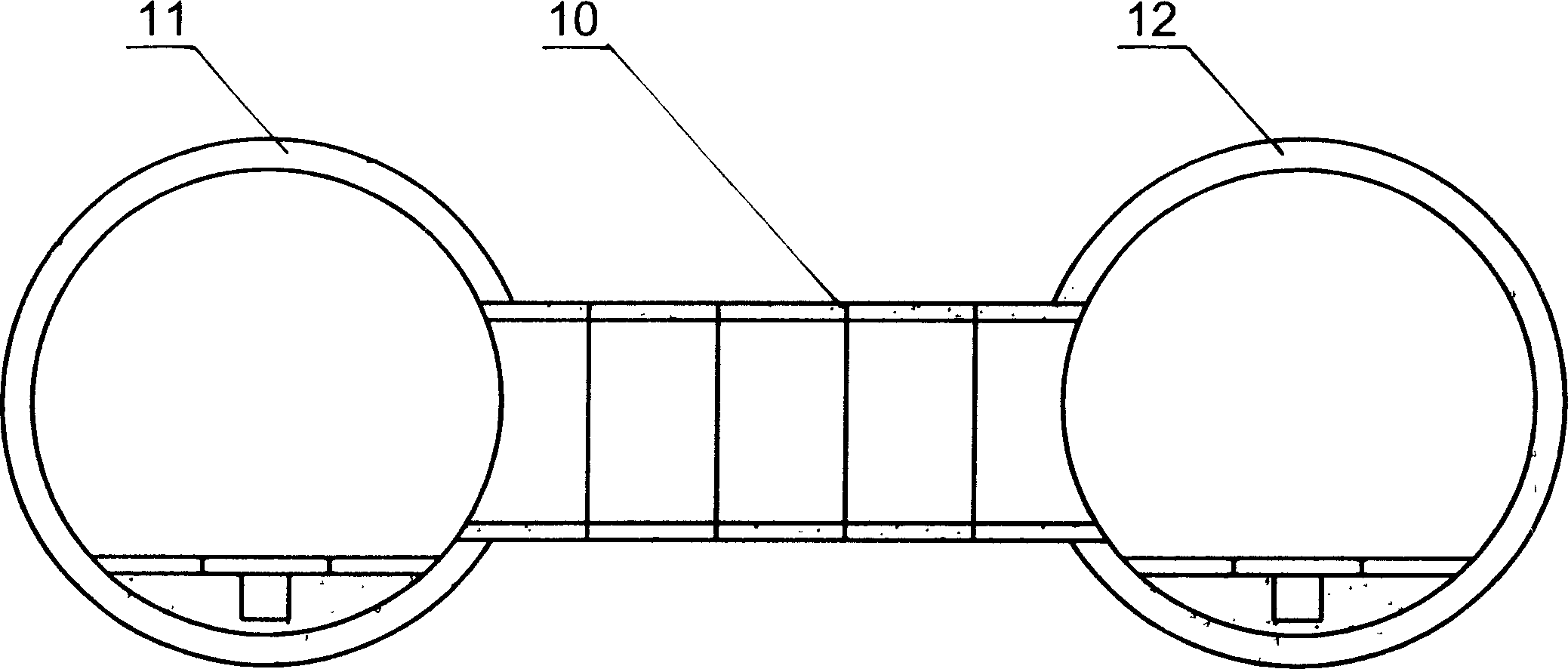

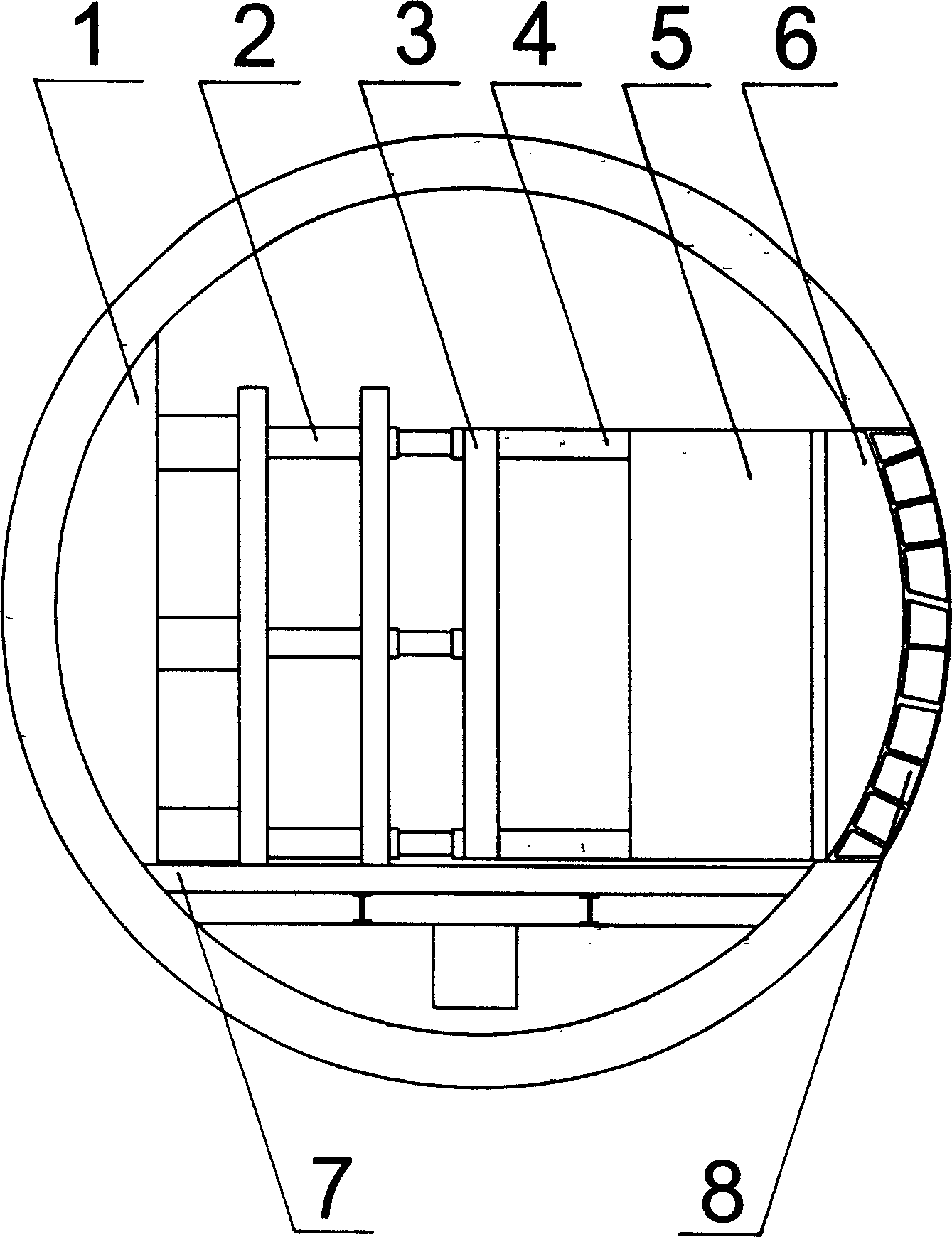

[0061] see figure 1 , taking the construction of a communication channel in a subway tunnel project as an example, a communication channel 10 needs to be built between the uplink tunnel 12 and the downlink tunnel 11 of the subway. 0.11m. The soil layers through which the communication channel 10 is jacked are ④ silty clay and ⑤ 1 clay.

[0062] The specific construction of the project is carried out according to the following steps:

[0063] 1. Soil reinforcement in the access and exit areas

[0064] Carry out foundation grouting reinforcement to the soil outside the concrete segment near the area of the concrete segment near the split rings [KR1] and [KL1] of the steel pipe segment 12 and 11 where the pipe jacking machine enters and exits the upper and lower tunnels 12 and 11, and the reinforced soil should have Very good self-suppor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Unconfined compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com