Method and equipment for recycling heat of returned air in mineral well

A technology for mine return air and heat recovery, which is applied in the ventilation, heating method and application of mines/tunnels. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

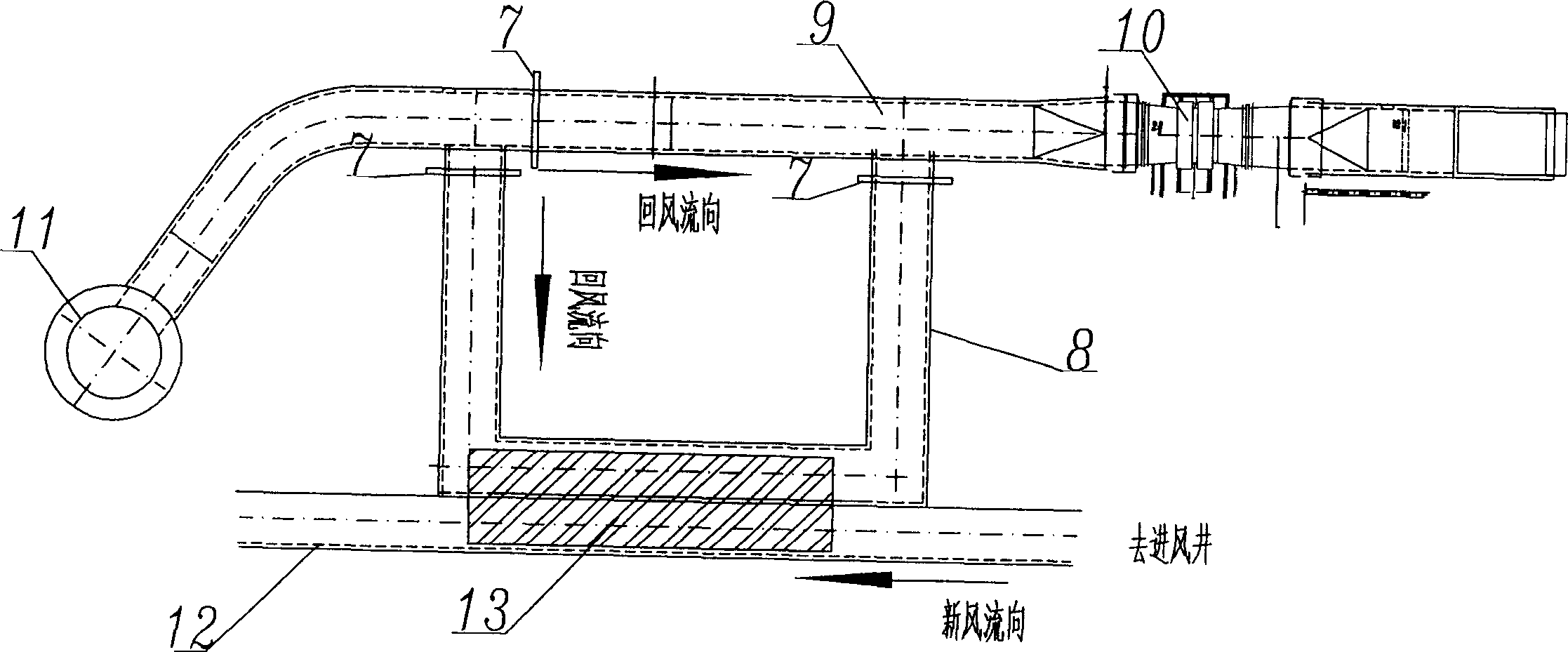

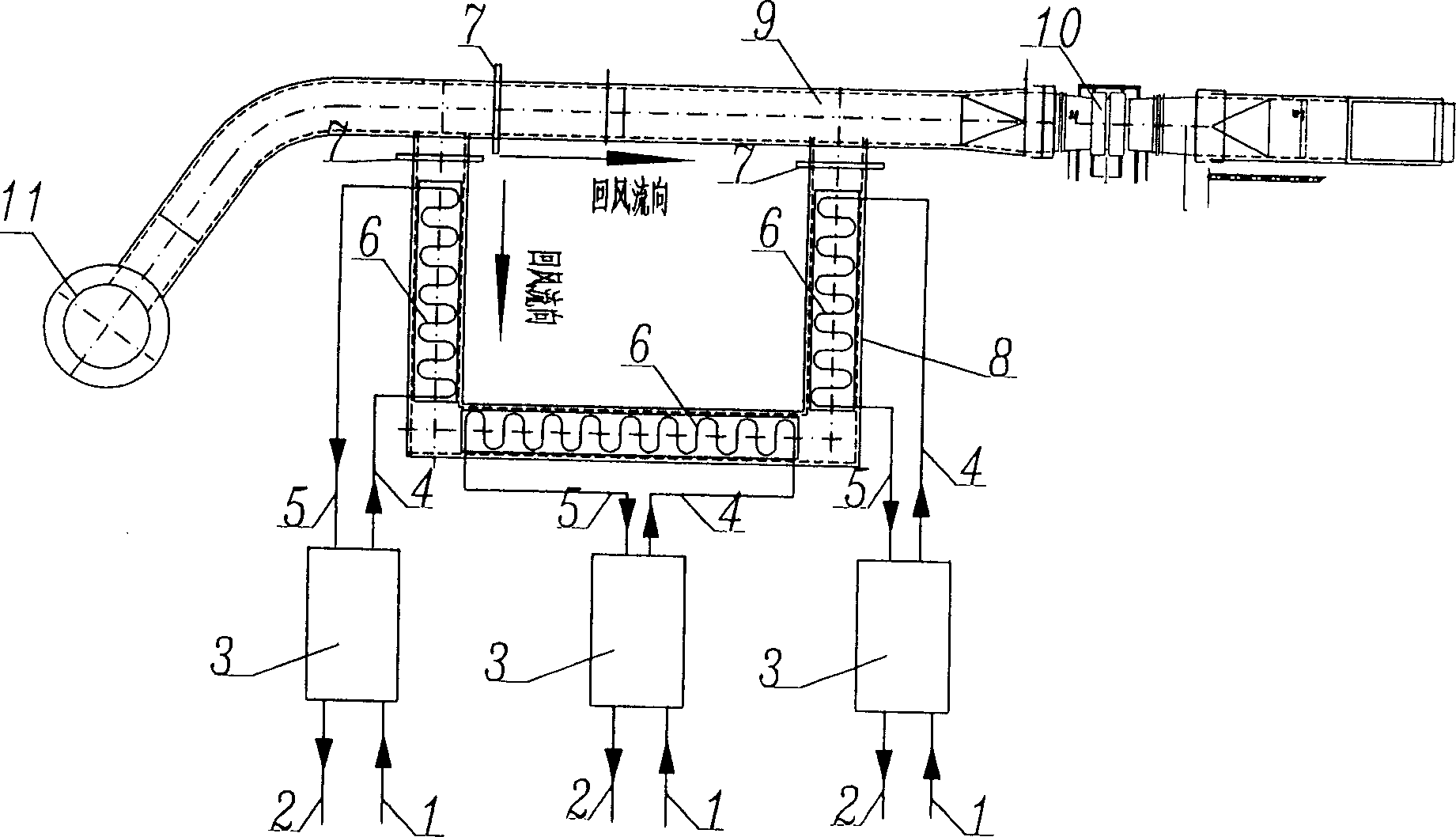

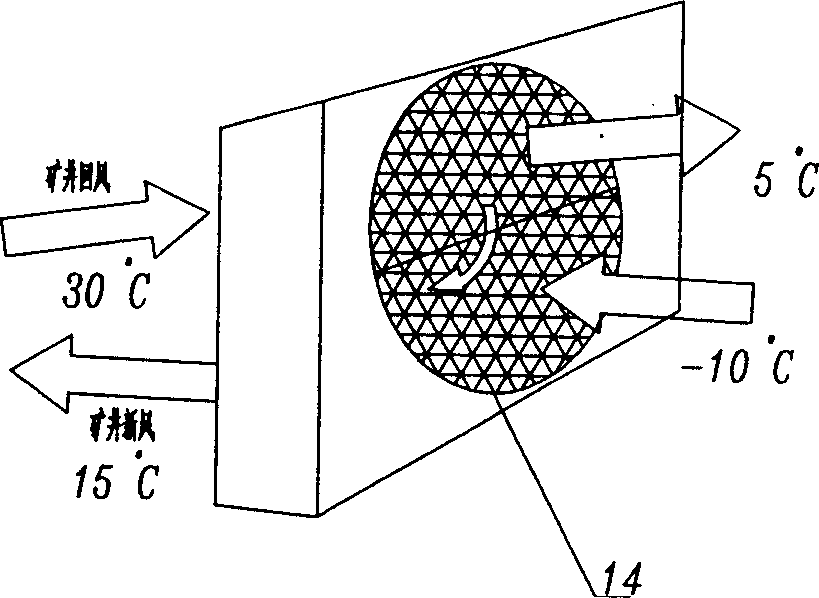

[0024] like figure 1 and figure 2 As shown, the mine return air heat recovery method of the present invention is provided with a bypass air duct in the air duct at the outlet of the return air shaft or in addition, and a heat exchanger is provided in the outlet air duct or the bypass air duct.

[0025] The heat recovery of the mine return air is used for the antifreeze of the shaft or the production or life of the mine. Mine return air heat recovery and utilization device, the heat exchanger method directly recovers mine return air heat. like figure 1 The implementation device shown mainly includes a regulating valve 7, a bypass air duct 8, a return air duct 9, a mine ventilator 10, a return air shaft 11, an air intake duct 12, and a double air duct type heat exchanger (heat exchanger) 13. On the air duct 9 at the outlet of the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com