Rod member and method for producing the same

A technology for rods and reinforcements, applied in building components, building reinforcements, pipes/pipe joints/pipes, etc., can solve the problems of difficult transfer, easy corrosion of rods, and heavy reinforced concrete.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

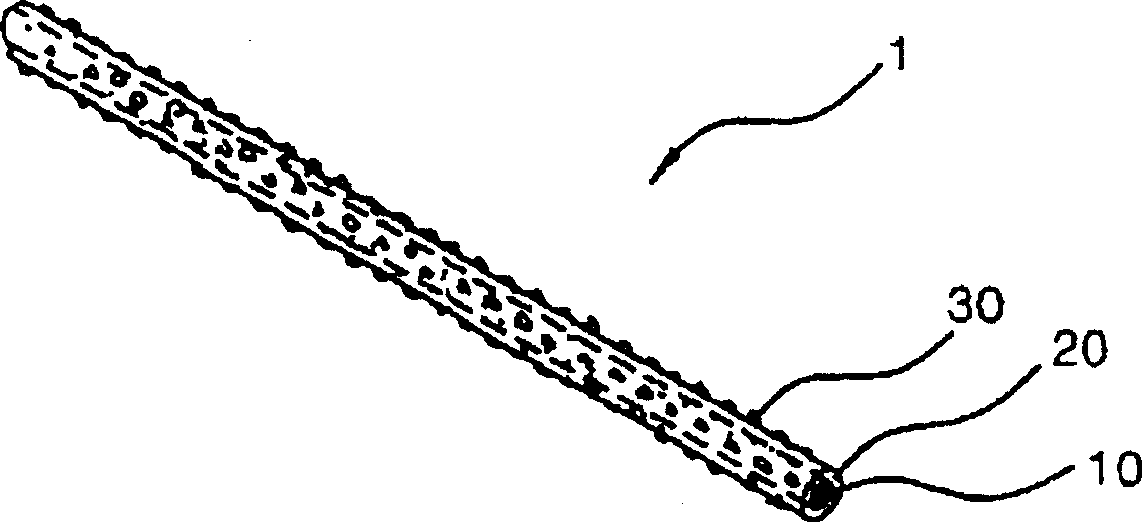

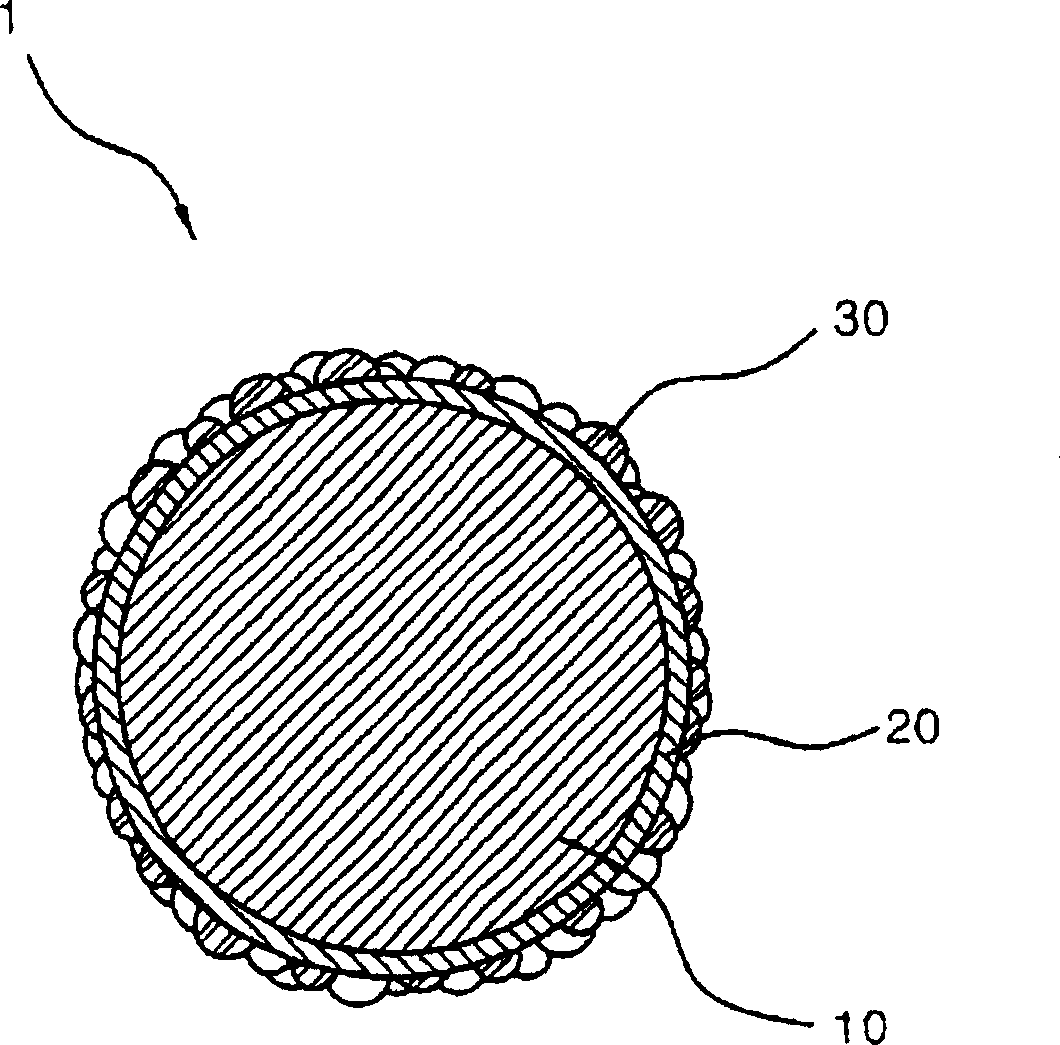

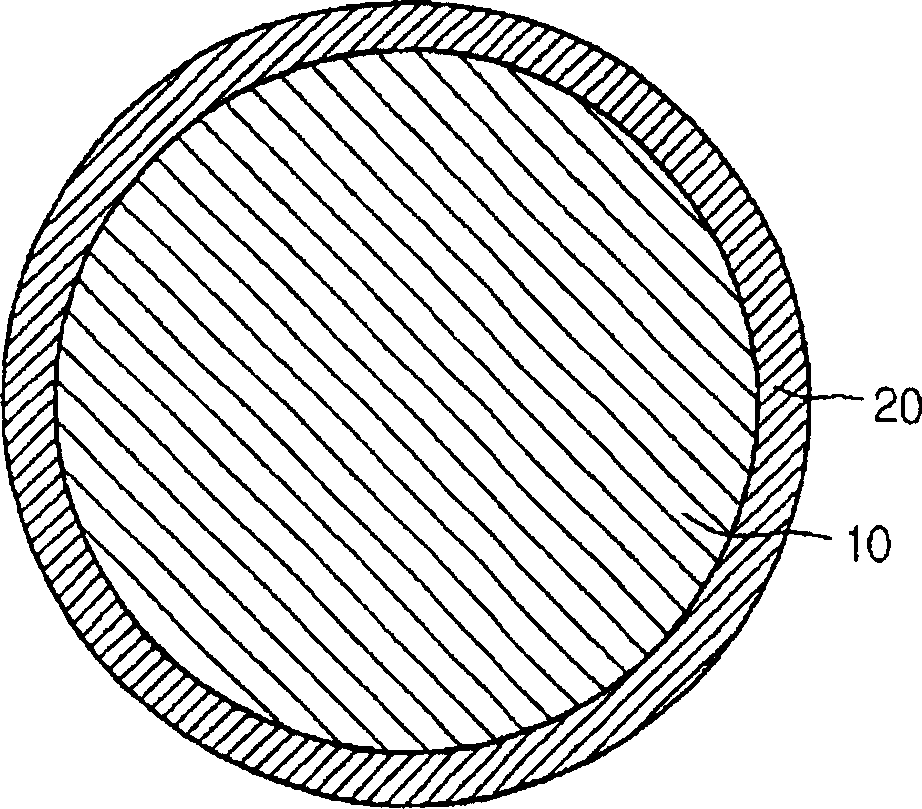

[0057] Rod-shaped aramid fibers are first prepared. A polyvinyl ester resin is formed on the outer periphery of the aramid fiber, thereby defining the rod. Here, the aramid fiber is 70 wt % with respect to the total weight of the rod, and the polyvinyl ester resin is 30 wt % with respect to the total weight of the rod.

[0058] The diameter of the rod made of aramid fiber and polyvinyl ester resin is about 9 mm.

[0059] Garnets each having a size of 300-800 μm were sprayed through the first and second spraying processes in a state where the polyvinyl ester resin was kept at a temperature of 60-80°C. The amount of garnet sprayed during the first spraying process was about 15 g / m, and the amount of garnet sprayed during the second spraying process was about 25 g / m.

[0060] Here, the pressure of the first injection process is about 1.02 N / mm 2 , while the pressure of the second injection process is about 1.02-5N / mm 2 .

[0061] Figure 4 The state of use of the rod accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com