Control apparatus for paper feeding and separating

A separation control and double sheet technology, applied in the direction of pile separation, object separation, object supply, etc., can solve the problems of limiting the application effect and scope of paper processing equipment, unsatisfactory processing of paper with poor surface quality, etc., to achieve double sheet separation. Reliable, widely used effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

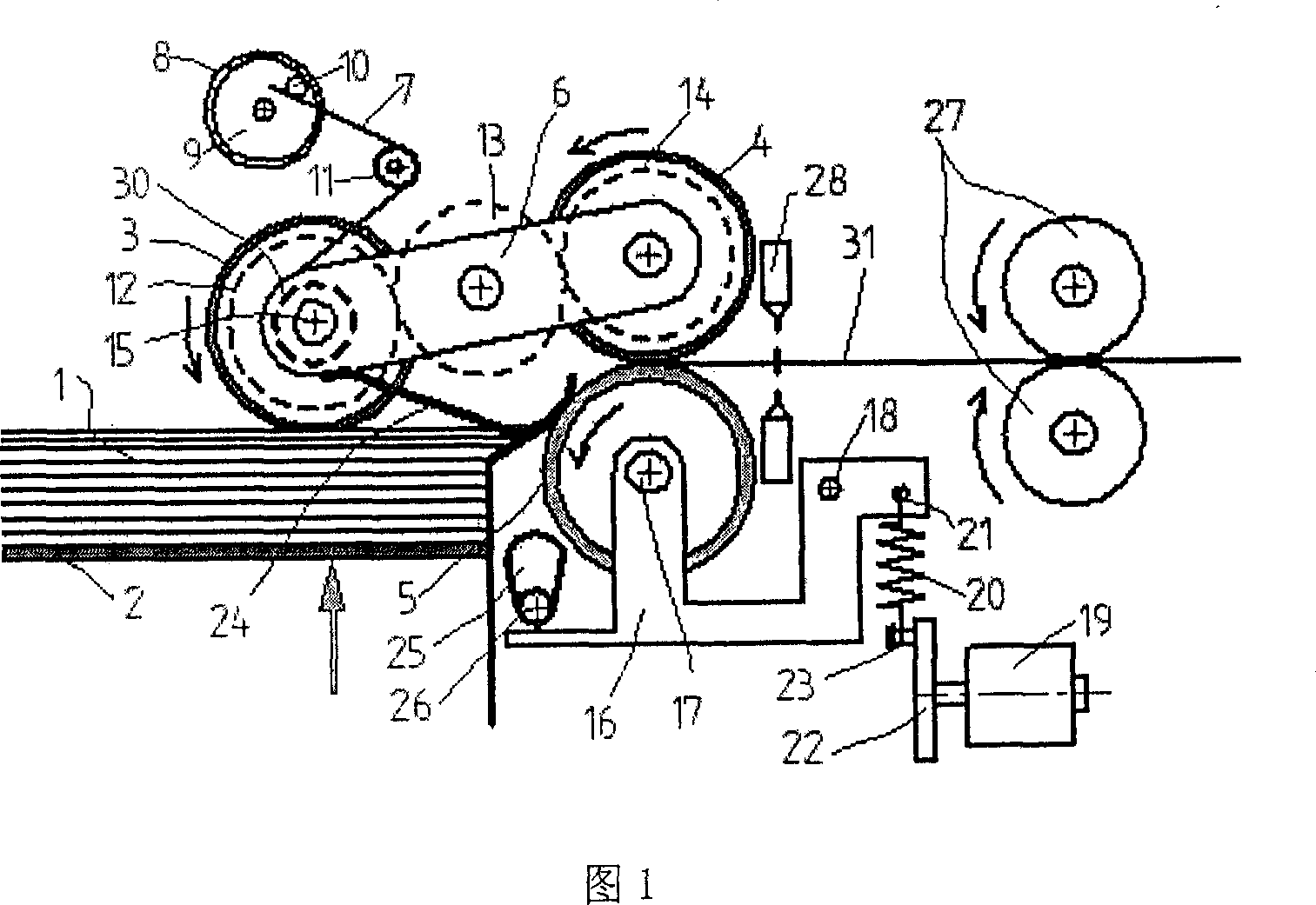

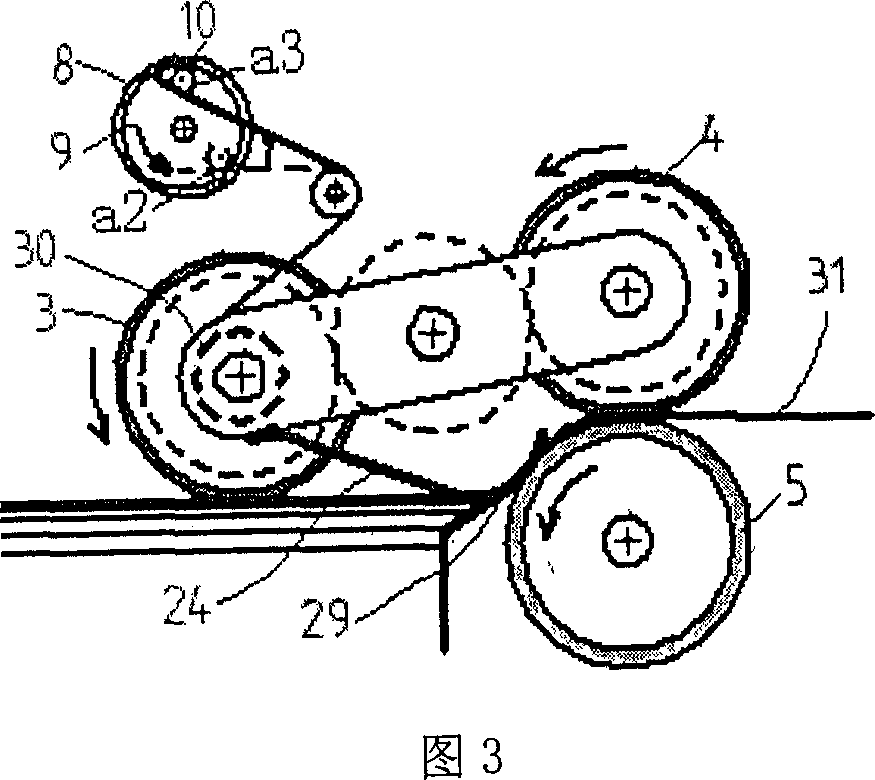

[0030] The structure of the present invention is as shown in Figure 1, including a paper pickup mechanism, a paper pickup pressure adjustment mechanism, a heavy sheet separation control mechanism, and a manual paper feeding adjustment mechanism. base connection.

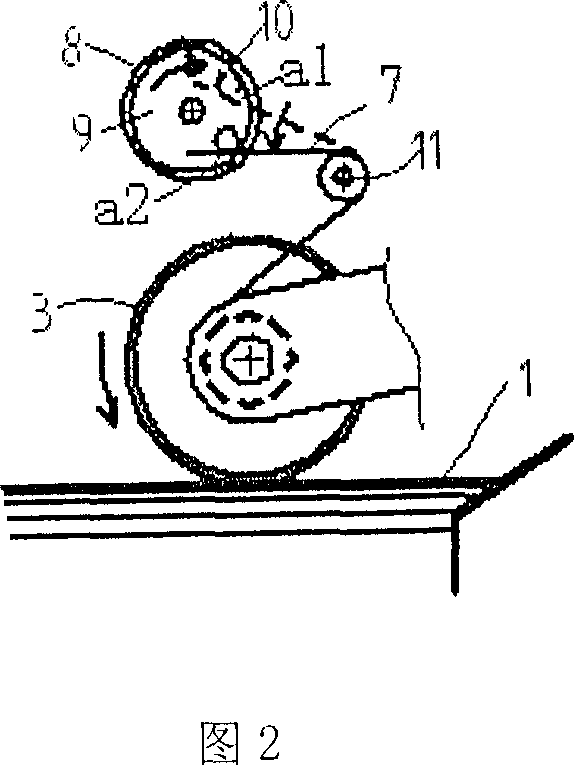

[0031] Described paper pick-up mechanism comprises pick-up wheel (3), clutch (30), pick-up wheel axle (15), gear a (12), gear b (13), gear c (14) and support (6), support (6) The right end is a rotatable support; the pick-up wheel (3) with the built-in clutch (30) is coupled with the bracket (6) through the pick-up wheel shaft (15); the gear b (13) is connected to one end of the pick-up wheel shaft (15) Above; gear c, gear b, gear a are associated with the bracket. When the pickup motor starts, the power is transmitted through gear c, gear b, and gear a. Because the clutch (30) is in the ON state, the clutch (30) drives the pickup wheel (3) to rotate to perform the pickup action; when the pickup action is completed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com