Energy-saving technique for producing high-purity pentane and pentane foaming agent

A technology of high-purity pentane and process, which is applied in the field of production of high-purity pentane and pentane blowing agent, can solve the problems of high production energy consumption, and achieve the effects of cost reduction, high purity and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

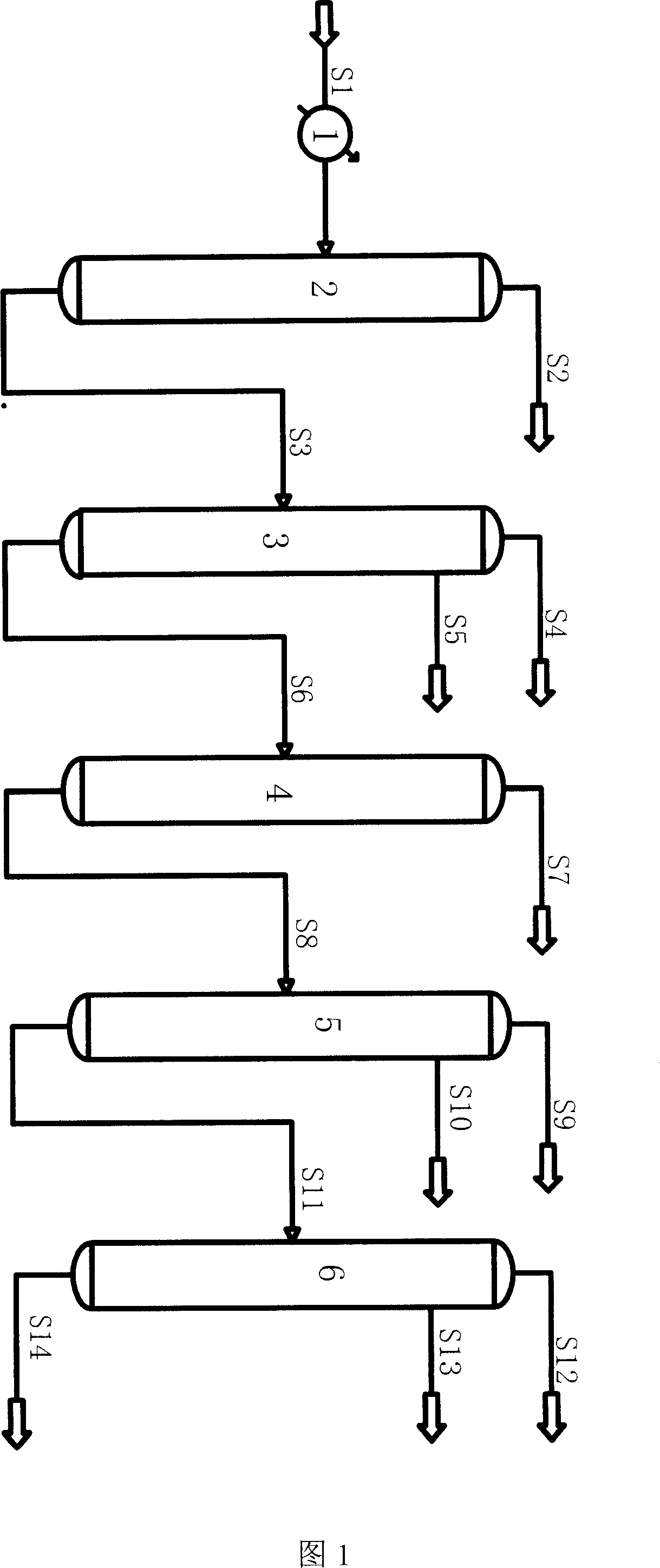

[0025] Example 1:

[0026] Component

[0027] The temperature of the feed S1 is normal temperature, pressurized to 0.55MPa, preheated by preheater 1 to 80.0℃, and then enters the middle of the light removal tower 2, where the C4 component S2 is removed from the top of the tower, and the inside of the light removal tower is plate wave type Structured packing and two-stage trough-type distributor, the operating pressure is 0.55MPa, the temperature at the top of the tower is 55℃, and the temperature at the bottom of the tower is 97℃, the bottom product S3 enters the isopentane tower 3; inside the isopentane tower is Wire mesh type structured packing and secondary trough type distributor, operating pressure is 0.25MPa, tower top temperature is 57℃, tower bottom temperature is 73℃, the top of the tower is equipped with a light component enrichment section, the top of the tower is enriched The light component S4 is returned to the raw material tank, the isopentane product S5 w...

Example Embodiment

[0028] Example 2:

[0029]The raw materials are the same as in Example 1. The temperature of feed S1 is normal temperature, pressurized to 1.0MPa, preheated to 100℃ by preheater 1, and then enters the middle of light removal tower 2, where C4 component S2 is removed from the top of the tower, light removal tower Inside is a plate wave type structured packing and a secondary trough type distributor, the operating pressure is 0.85MPa, the top temperature is 77℃, the bottom temperature is 118℃, the bottom product S3 enters the isopentane tower 3; The alkane tower is equipped with wire mesh structured packing and a secondary trough type distributor. The operating pressure is 0.45MPa, the top temperature is 79℃, and the bottom temperature is 94℃. The top of the tower is equipped with a light component enrichment section. , The light component S4 enriched at the top of the tower is returned to the raw material tank, the isopentane product S5 with a purity of ≥99.0% (w / w, the same below)...

Example Embodiment

[0030] Example 3:

[0031] Component

[0032] The temperature of raw material S1 is normal temperature, pressurized to 0.55MPa, preheated to 98.0℃ by preheater 1, and then enters the middle of light removal tower 2, where C4 component S2 is removed from the top of the tower, and the light removal tower is filled with plate corrugated structured packing And the secondary trough type distributor, the operating pressure is 0.6MPa, the top temperature is 61.3℃, and the bottom temperature is 104.4℃, the bottom product S3 enters the isopentane tower 3; the inside of the isopentane tower is a wire mesh Type structured packing and secondary trough type distributor, operating pressure is 0.25MPa, tower top temperature is 56.2℃, tower bottom temperature is 73.8℃, the top of the tower is equipped with a light component enrichment section, and the light component is enriched at the top of the tower. The component S4 is returned to the raw material tank, and the isopentane S5 product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com