Frame structure for wheel type engineering machine

A technology of construction machinery and frame structure, which is applied in the direction of earth mover/shovel, construction, etc., can solve the problems of stability, low flexibility, large turning radius of the whole machine, poor bending moment bearing capacity, etc., to achieve Increased strength and rigidity, small turning radius, and enhanced bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

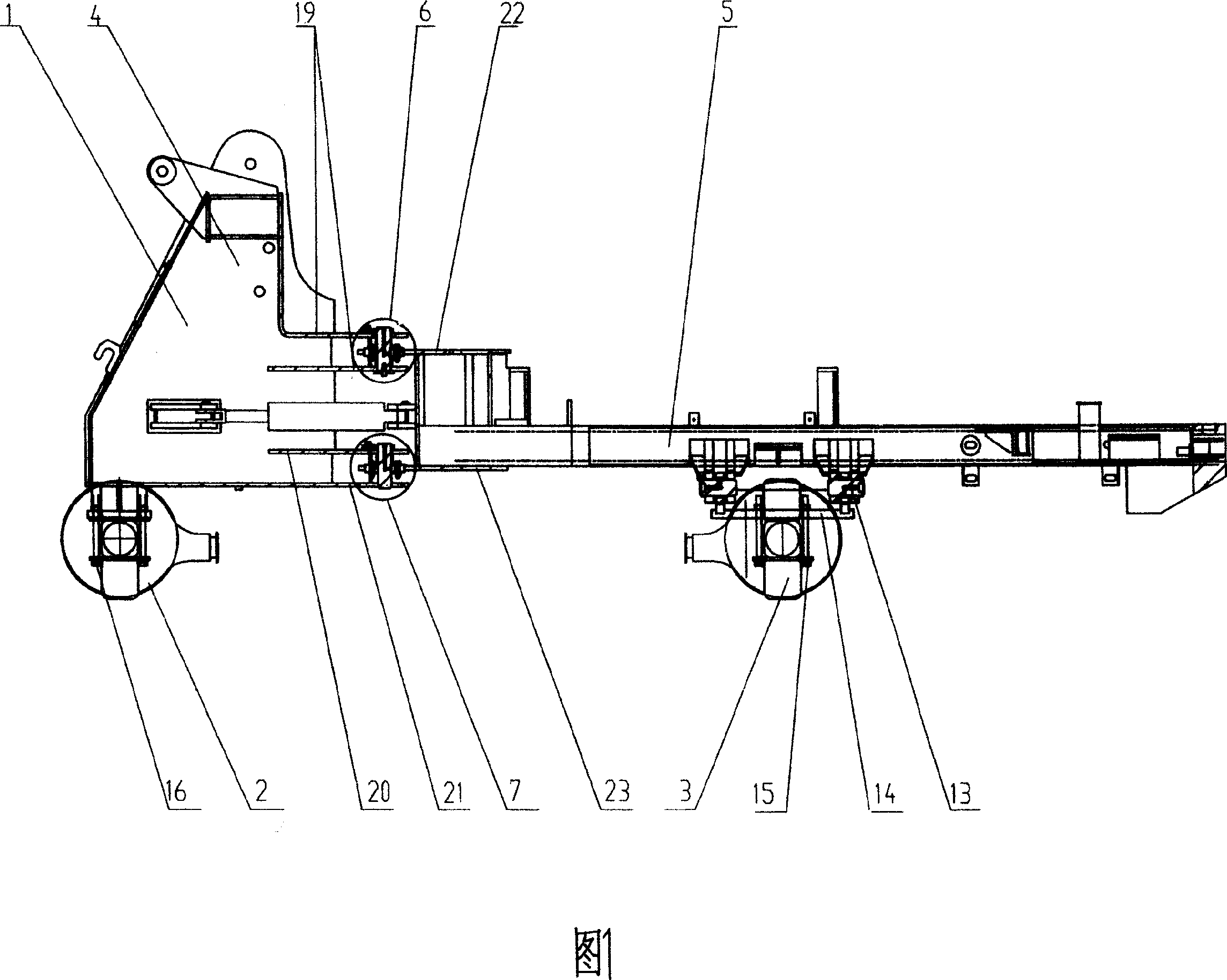

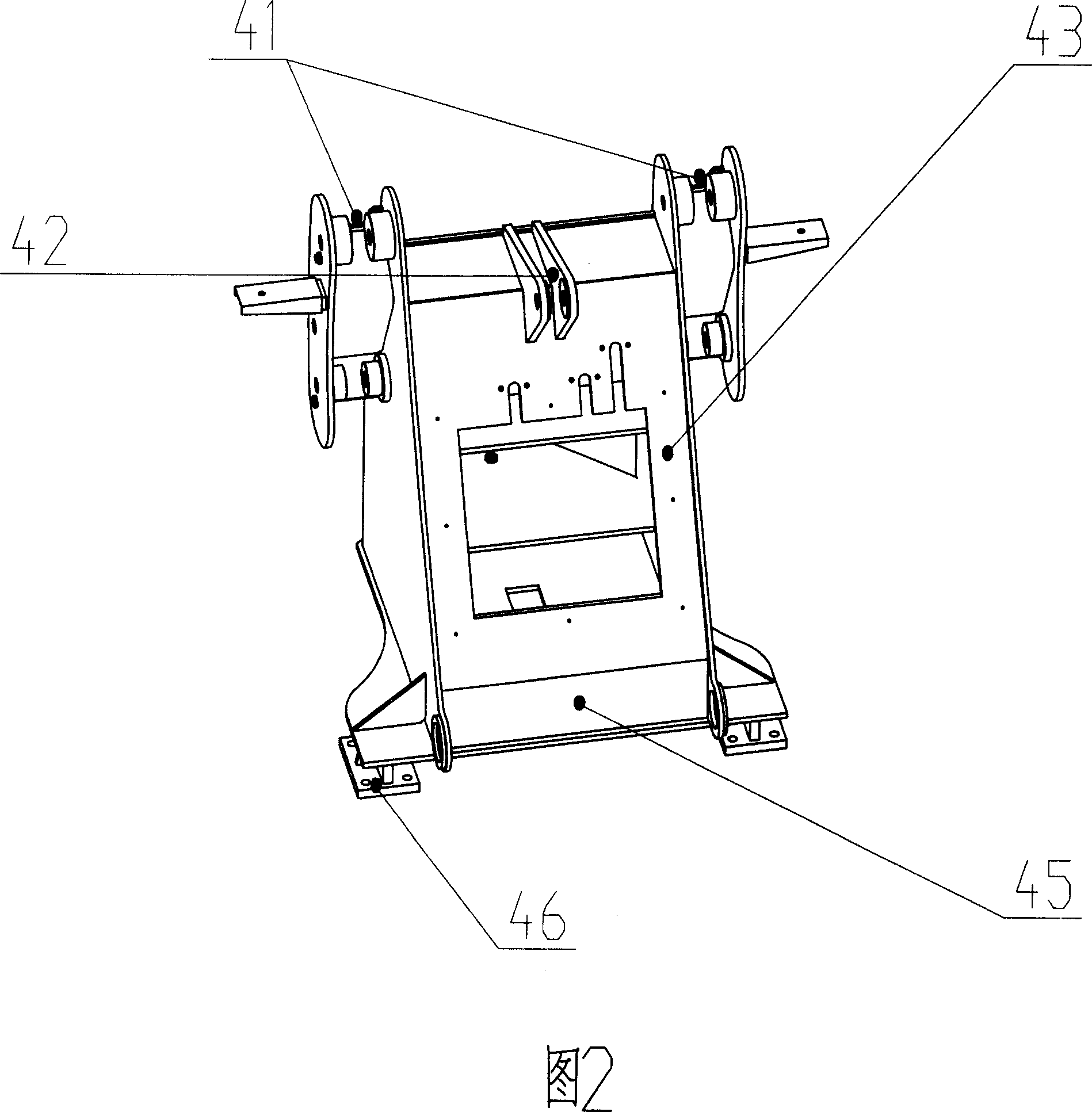

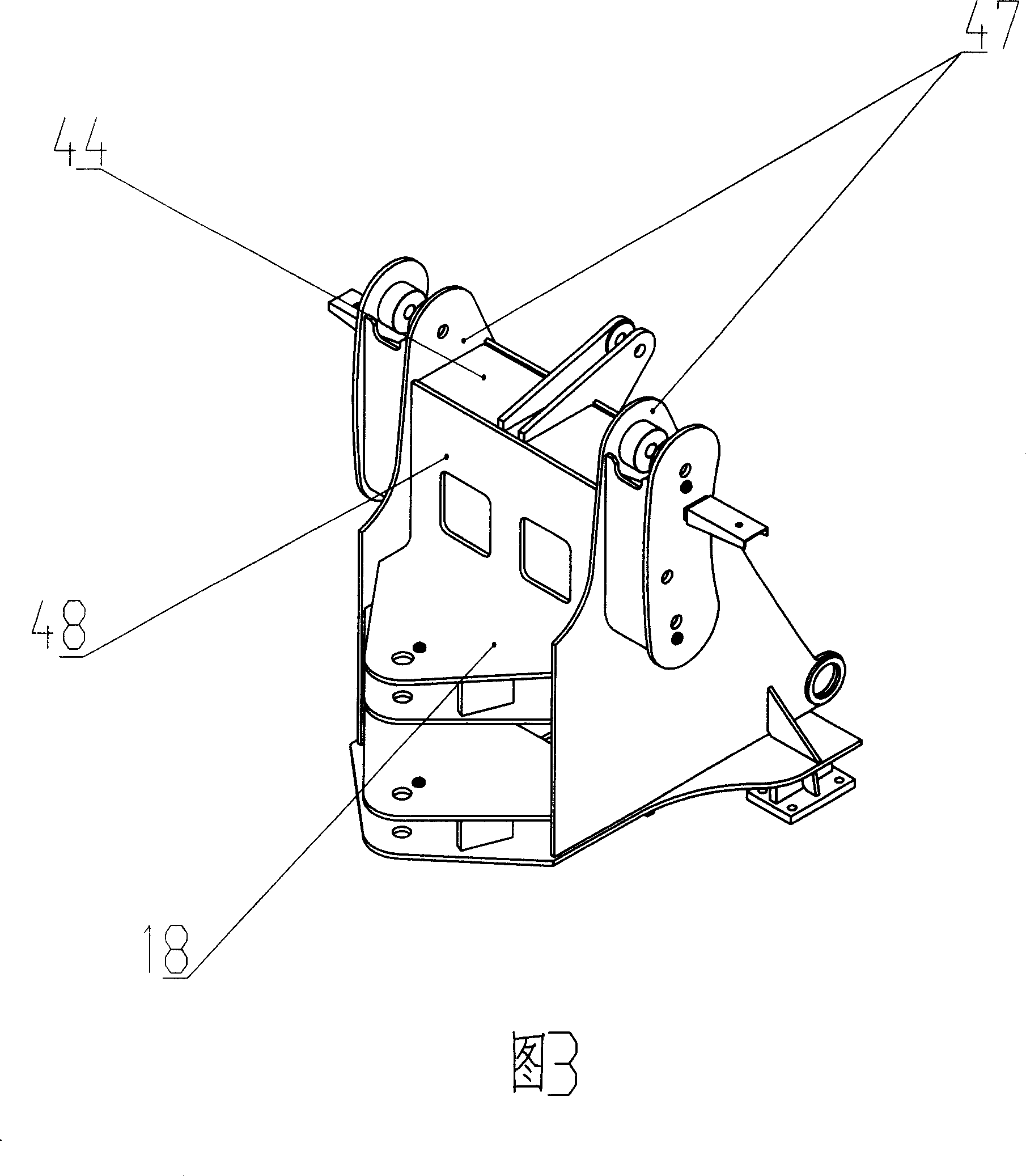

[0015] See Fig. 1, the frame structure of wheeled engineering machinery, including front frame 4, rear frame 5, front drive axle 2, rear drive axle 3, front frame 4 is a box structure, see Fig. 2, Fig. 3, it It is welded by the upper beam 44, the lower beam 45, the front panel 43, the rear panel 48, and the wing boxes 47 on both sides. The hinged frame 18 is arranged below the rear panel 48 , and the bridge mounting plate 46 is arranged at both ends of the lower beam 45 . The comprehensive mechanical properties of the box structure are greatly improved, prolonging its service life. As shown in Fig. 1, the front frame 4 and the rear frame 5 are connected by a slewing pair, which is located at the center of the wheelbase of the front and rear drive axles. The setting of this position can reduce the turning radius and improve the passability. This rotary pair is made ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com