Underwater intelligent purification robot for large-scale condensing plant

A technology for condensing equipment and intelligent cleaning, which is applied to the online cleaning of large condensers and the field of intelligent underwater cleaning robots for large condensing equipment. High, wide applicability, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

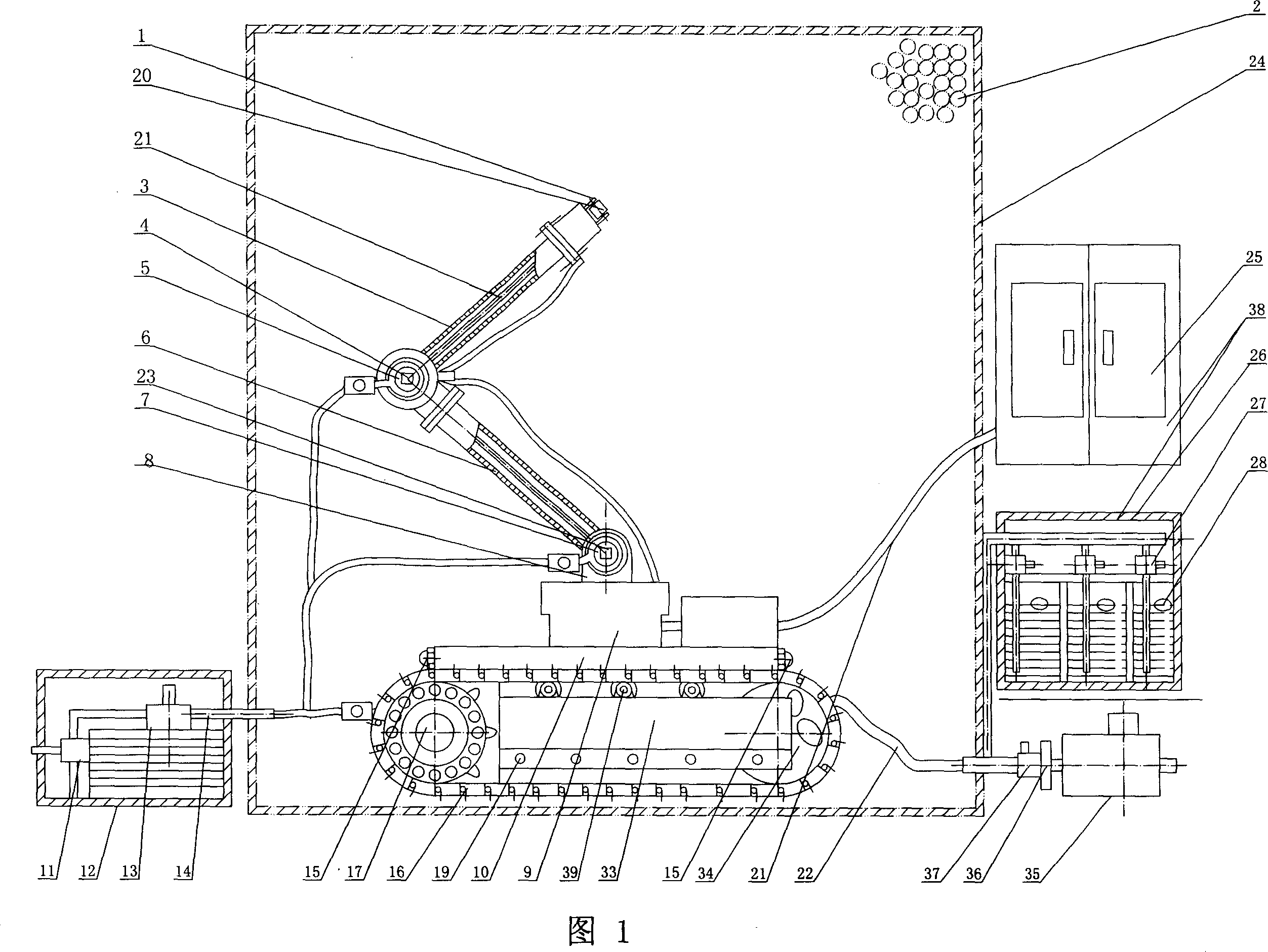

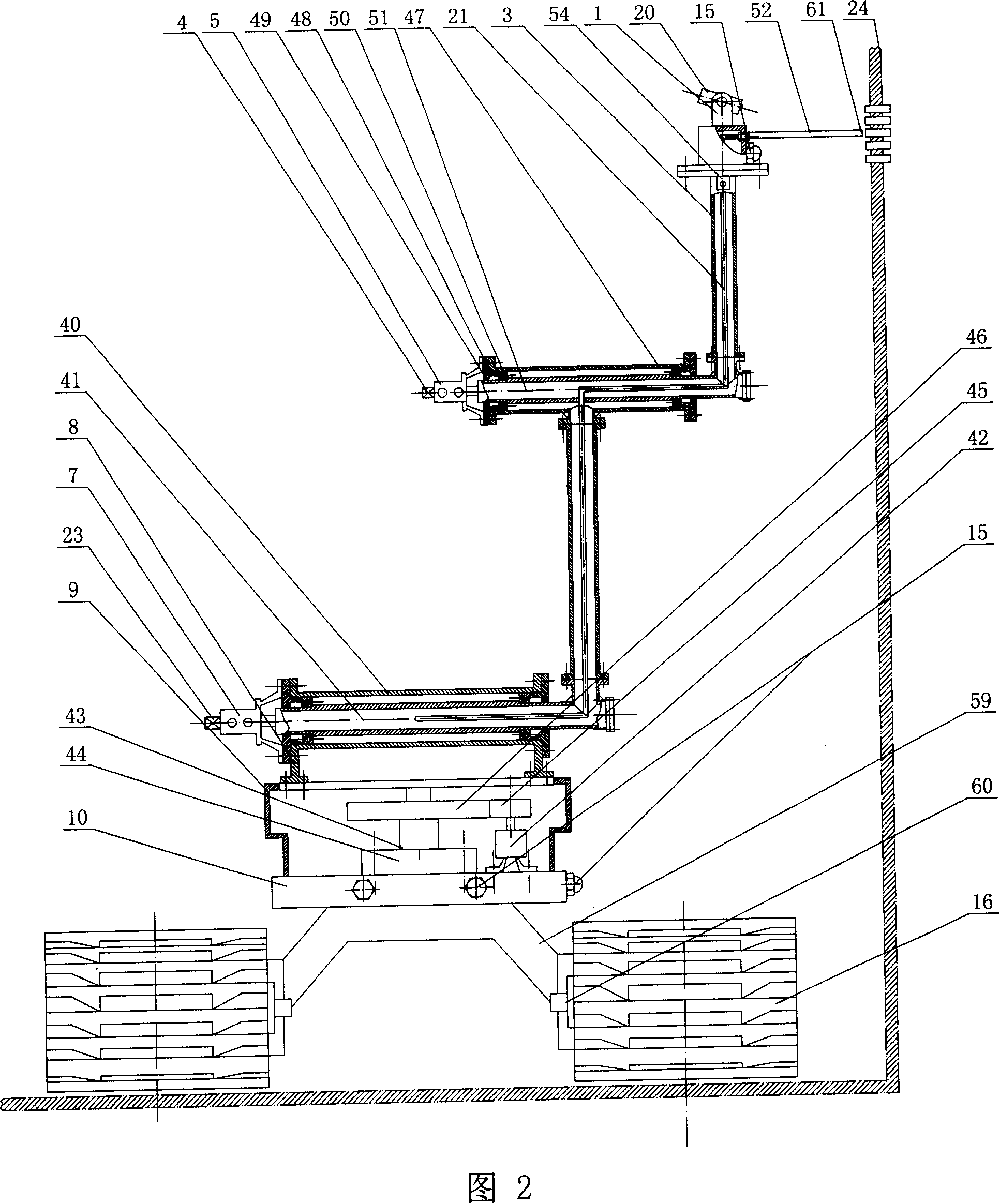

[0024] Further details will be described below in conjunction with the accompanying drawings and specific embodiments.

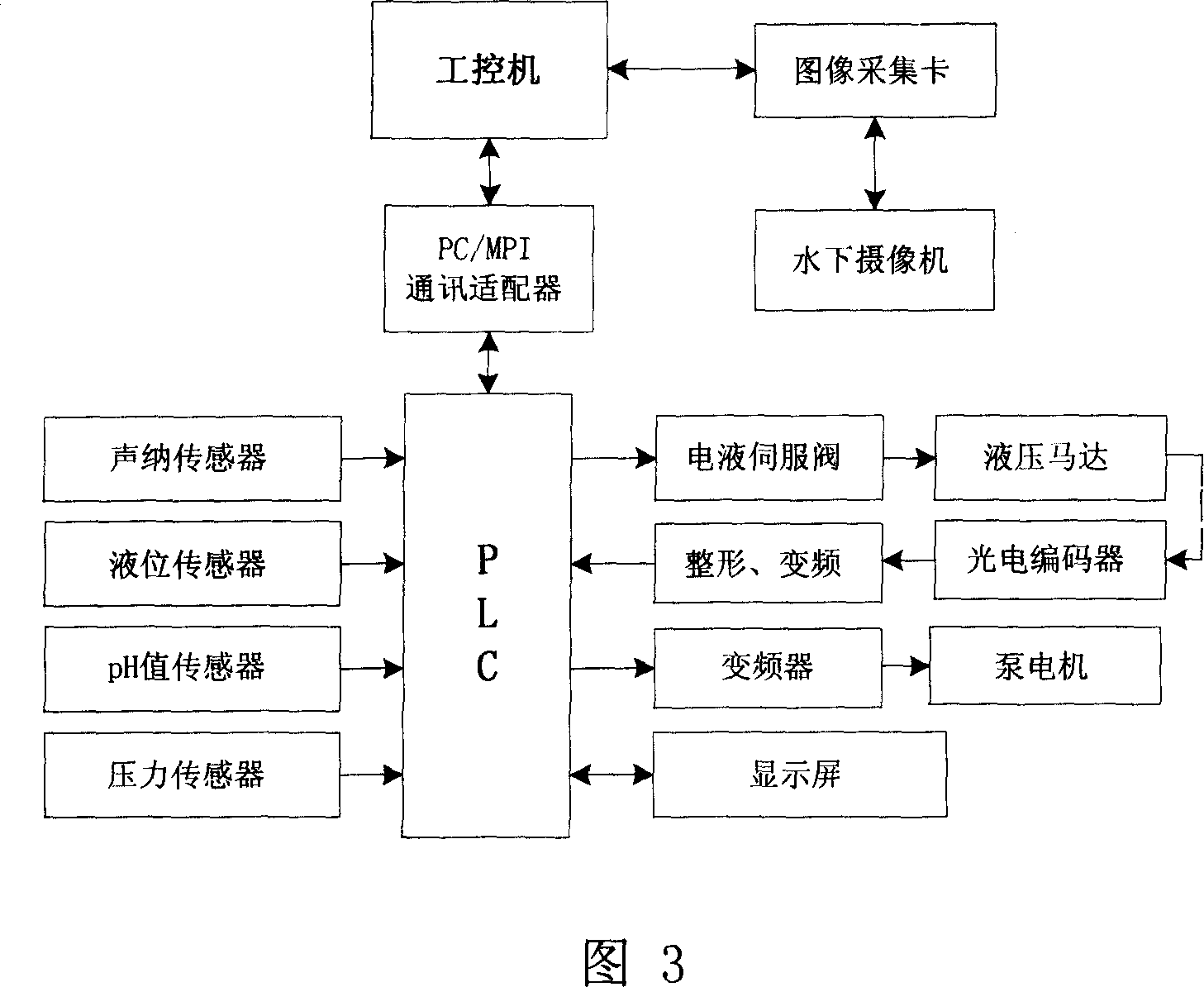

[0025] As shown in Fig. 1 and Fig. 2, the underwater intelligent cleaning robot for large-scale condensing equipment of the present invention includes a control mechanism and a cleaning mechanism connected to the control mechanism. The bottom end of the cleaning mechanism is provided with a walking mechanism, and the cleaning mechanism includes a spray gun body 52 , image acquisition device 20, small arm assembly, large arm assembly, slewing mechanism assembly, connecting pipe 22 and cleaning medium source 38, described small arm assembly includes small arm 3, small arm drive device 5 and small arm drive Shaft 51, one end of forearm 3 is installed on the forearm drive shaft 5, and the other end of forearm 3 is equipped with spray gun body 52 and image acquisition device 20, and spray gun body 52 links to each other with cleaning medium source 38 by communicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com