Underwater glider floatage control device

An underwater glider and control device technology, which is applied to underwater ships, underwater operation equipment, motor vehicles, etc., can solve problems such as difficulty in deep-sea development, and achieve the effect of convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

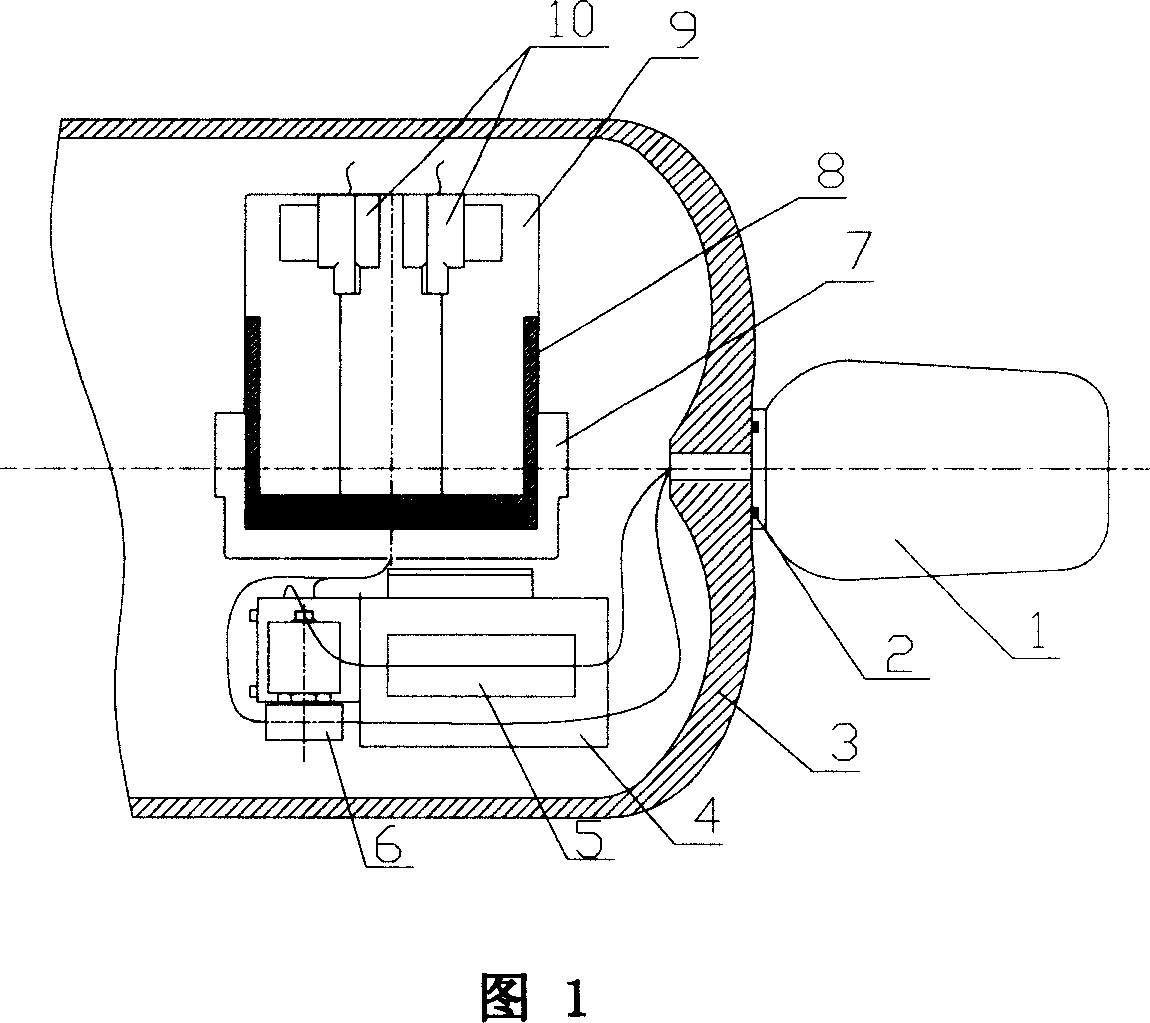

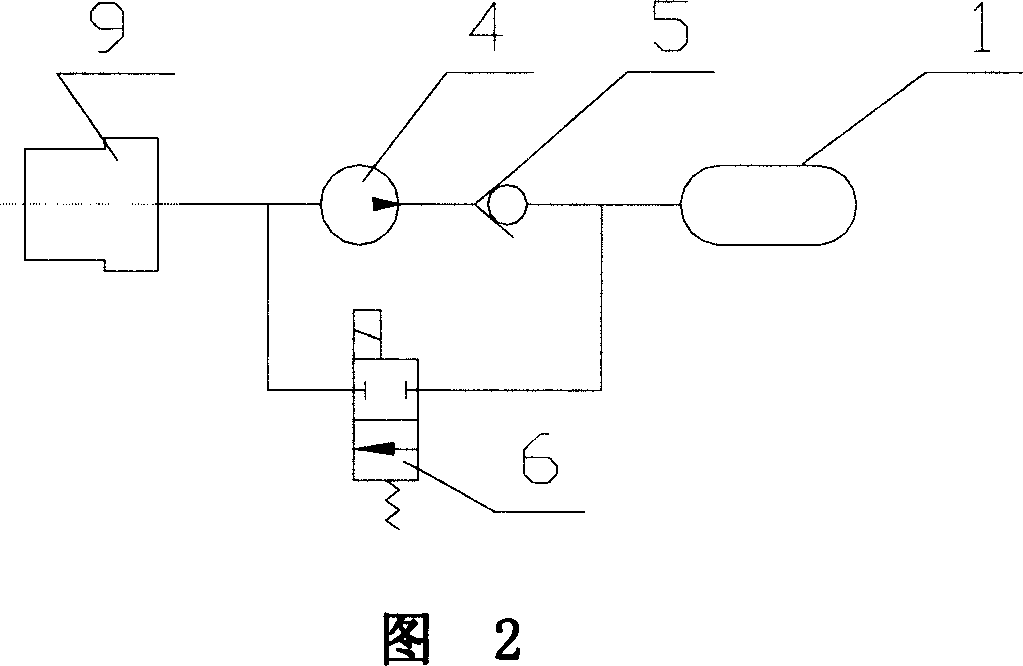

[0008] As shown in FIGS. 1 and 2 , the buoyancy control device of the underwater glider includes a small high-pressure pump 4 , a small solenoid valve 6 , a small one-way valve 5 , an oil chamber 9 and an oil bag 1 . Small high-pressure pump 4, small solenoid valve 6, small one-way valve 5 and oil cavity 9 are arranged inside pressure-bearing shell 3; oil bag 9 is arranged outside pressure-bearing casing 3, and the surface is in direct contact with seawater. The connection between the oil bag 1 and the pressure housing 3 is sealed with an o-ring 2 . The oil chamber 9 is composed of a chamber body 7 , a piston 8 and two linear potentiometers 10 . The oil chamber 9 and the oil bag form a circuit through a small high-pressure pump 4 and a small one-way valve 5, and are communicated through a small electromagnetic valve 6 at the same time. The function of the small one-way valve 5 is to prevent the oil in the circuit from flowing back to the oil chamber 9 through the small high-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com