Detergent for water-based print ink

A technology for printing ink and cleaning agent, applied in the field of water-based printing ink cleaning agent, can solve problems such as damage to printing presses and rubber rollers, weak cleaning power of the cleaning agent, etc., and achieve the effects of no environmental pollution and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with embodiment.

[0013] 1. Formula of water-based printing ink cleaning agent

[0014] The water-based printing ink cleaning agent is composed of water, surfactant BEE, polyoxyethylene ether, inorganic base and fatty acid ester with 4-8 carbon atoms, and its typical ratio is shown in Table 1.

[0015] Surfactant BEE

(g)

polyoxyethylene ether

(g)

Inorganic base

(g)

(g)

water

(g)

40

20-30

20-30

10-30

1870-1910

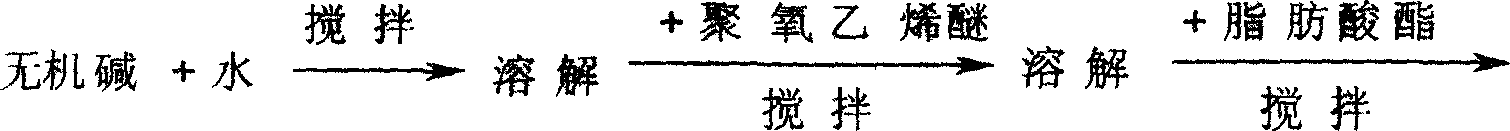

[0016] 2 Preparation process

[0017] The preparation process of water-based printing ink cleaning agent is as follows:

[0018]

[0019]

[0020] The specific process is as follows: add 1600mL water into a 3L beaker, add 20-30g inorganic alkali, start the stirrer, and dissolve into a clear solution. Then add 20-30g of polyoxyethylene ether, stir to dissolve, add 10-30g of fatty ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com