Forage grass maize production process

A production method and technology of forage corn, applied in botany equipment and methods, plant genetic improvement, horticulture, etc., can solve problems such as low seed setting rate and difficulty in direct hybridization, and achieve strong stress resistance and cold resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

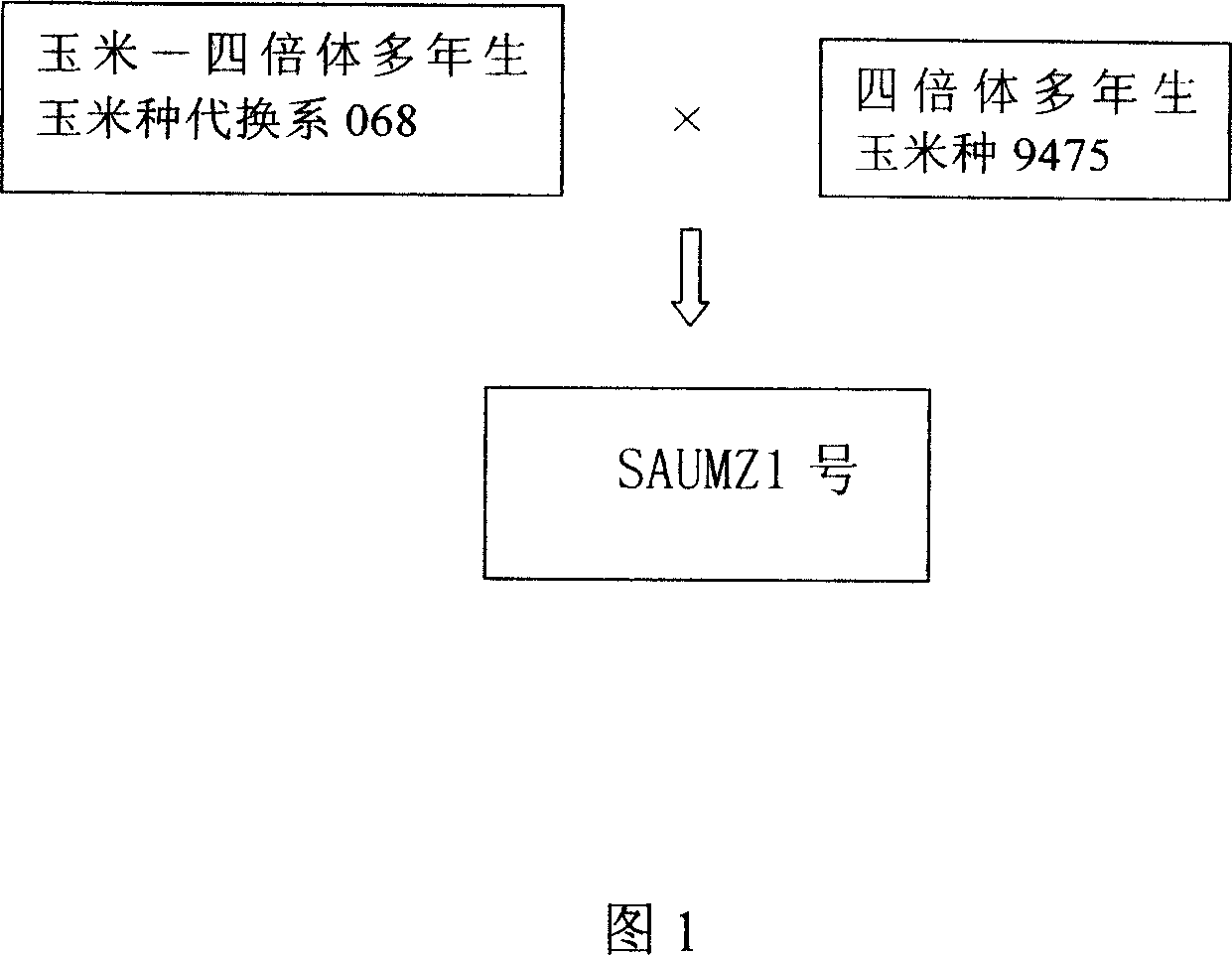

Embodiment 1

[0025] In the autumn of 2004 in Yunnan 6667m 2 Seeds of forage corn SAUMZ1 are produced on the land in the land, and the seed production area adopts spatial isolation, and the space isolation distance is 500 meters, that is, no corn is planted at a distance of 500 meters around the seed production area; because the male parent tetraploid perennial maize species 9475 The flowering period is about one month, so the female parent corn-tetraploid perennial corn variety substitution line 068 was sown in stages from early September, and a batch was sown every 5-7 days. The planting density of the female parent was 2780 plants / 666.7m 2 , planted in wide and narrow rows, the wide row spacing is 120cm, the narrow row spacing is 80cm, and the plant spacing is 30cm; manual emasculation is used, and all the tassels of the female parent 068 are removed during the tasseling stage; the male parents are planted together, and the plant row spacing is 80×80cm. The paternal tetraploid perennia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com