Knife holding net box for thin knift paper separator

A technology of clamping knives and cages, applied in the direction of machining/deformation, etc., can solve the problems of difficulty in discharging paper scraps, inconvenient maintenance, asynchronous and other problems, and achieve the effect of avoiding the phenomenon of knife collision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and the prior art.

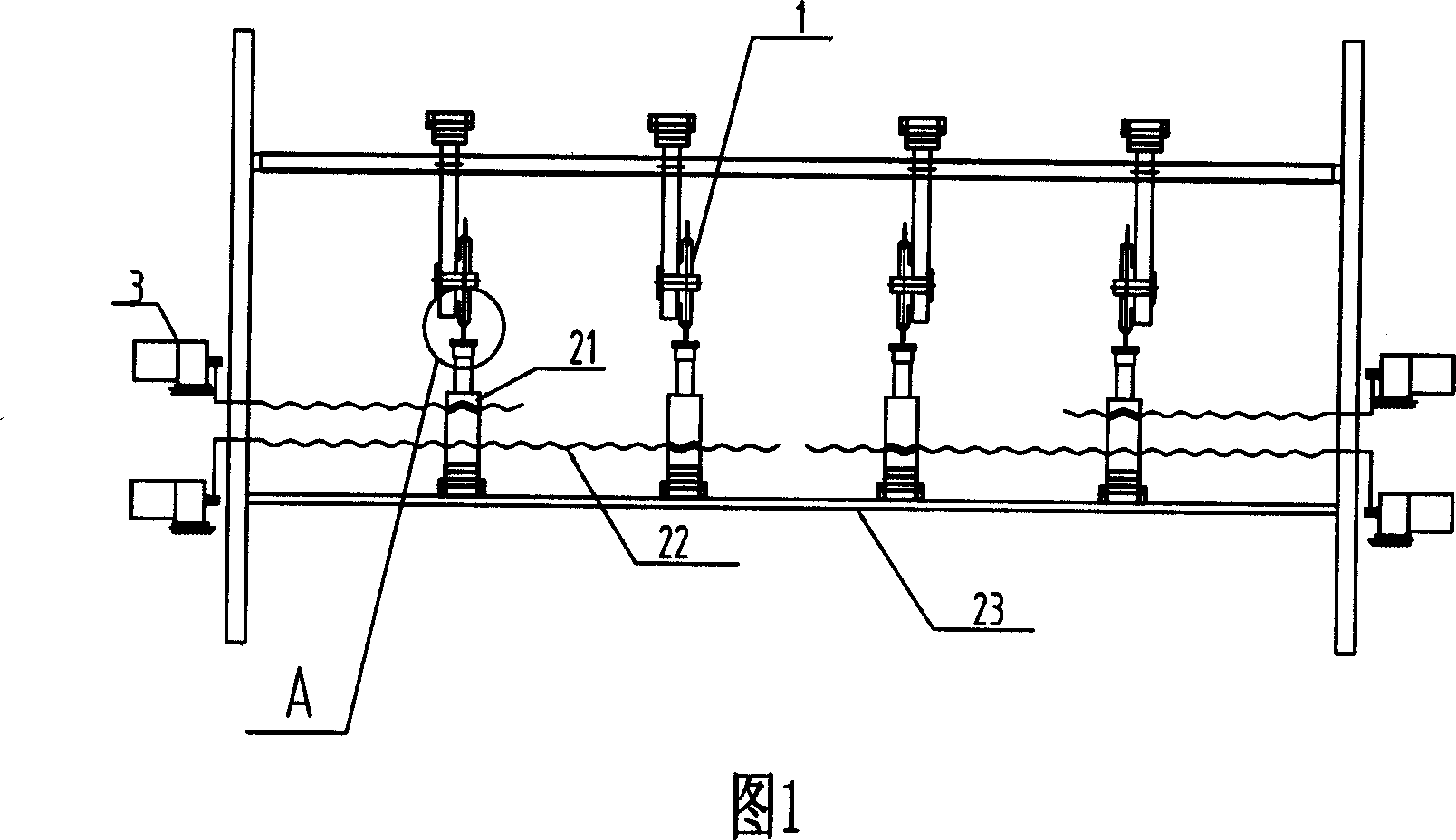

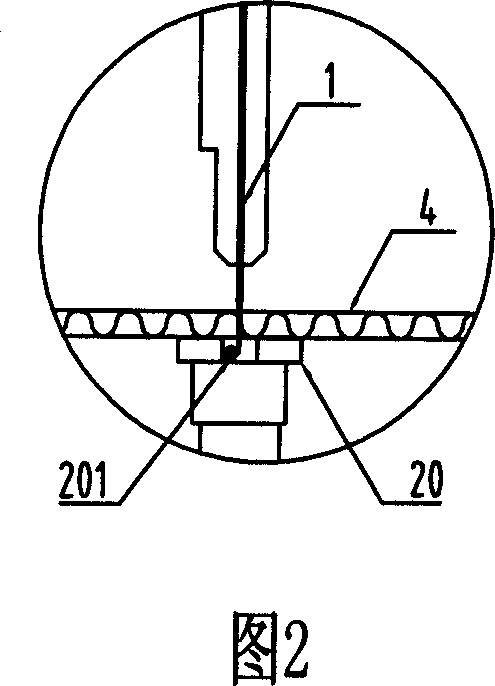

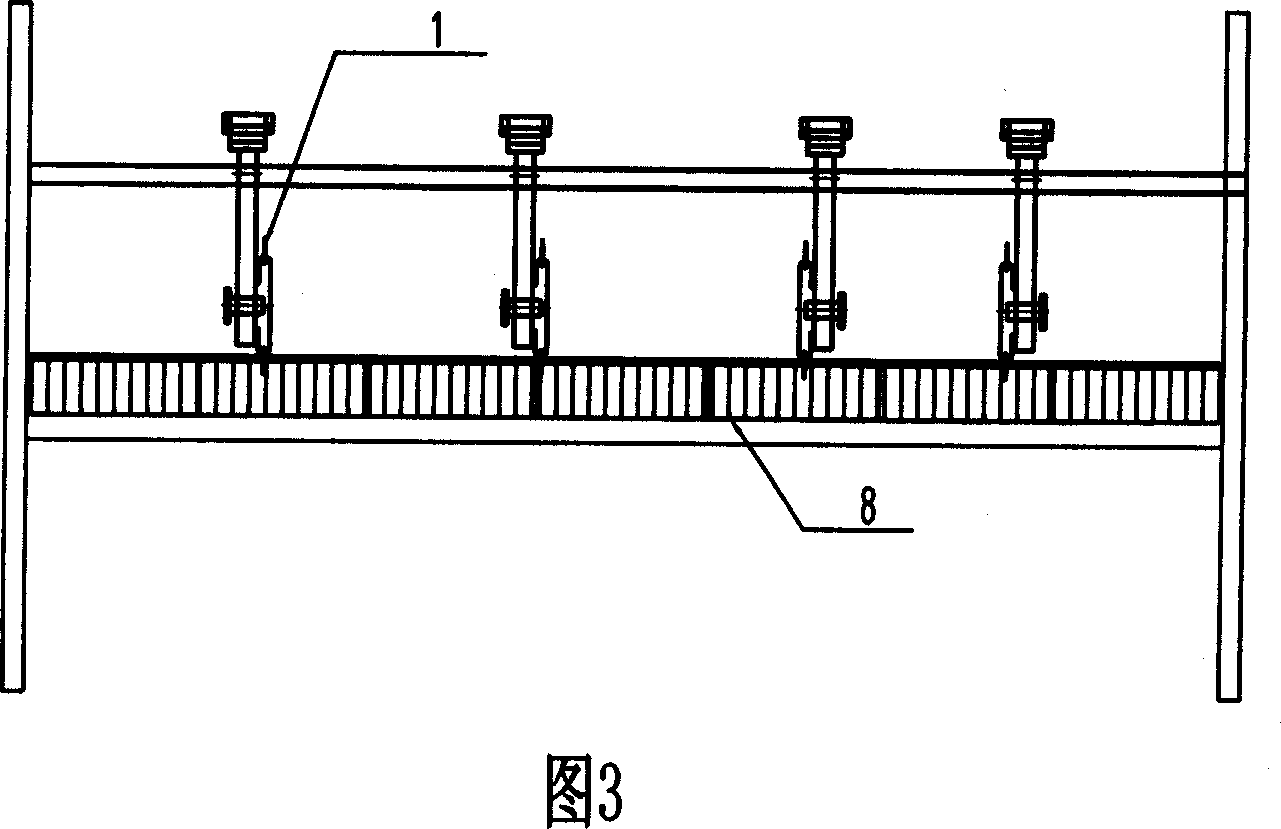

[0026] Fig. 1 shows the thin-knife paper separator of the prior art, and the bottom of each group of cutters 1 is simultaneously provided with a clamping plate 20, and the clamping plate 20 is connected on the lower knife seat 21, and the lower knife seat 21 is controlled by a screw rod 22. driven, and then controlled by the motor 3 to move left and right on the linear guide rail 23 and keep in sync with the cutter 1. Figure 2 is a partial enlarged structural diagram of the paper separator when separating paper, which is located on the clamping plate 20 directly below the cutter 1 There is a 3mm slot 201. When separating the paper, the cutter 1 falls into the slot 201 after separating the cardboard 4, which is a normal working state. However, because the size of the paper needs to be changed frequently, the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com