Renminbi double-side offset printing, on-line detecting, automatically separating and collecting process

An automatic separation, double-sided tape technology, applied in printing, printing presses, stack receiving devices, etc., to achieve the effect of solving stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

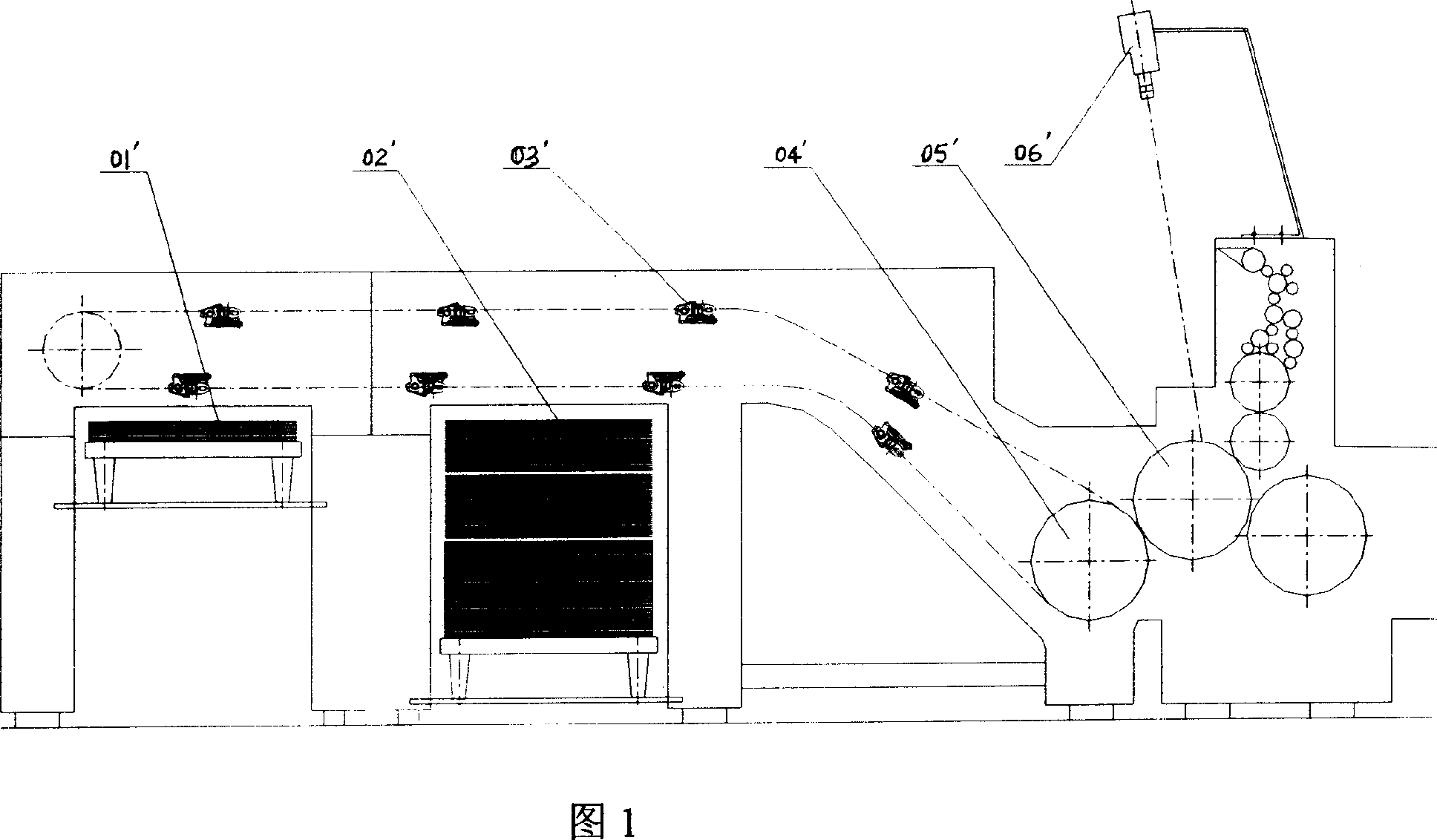

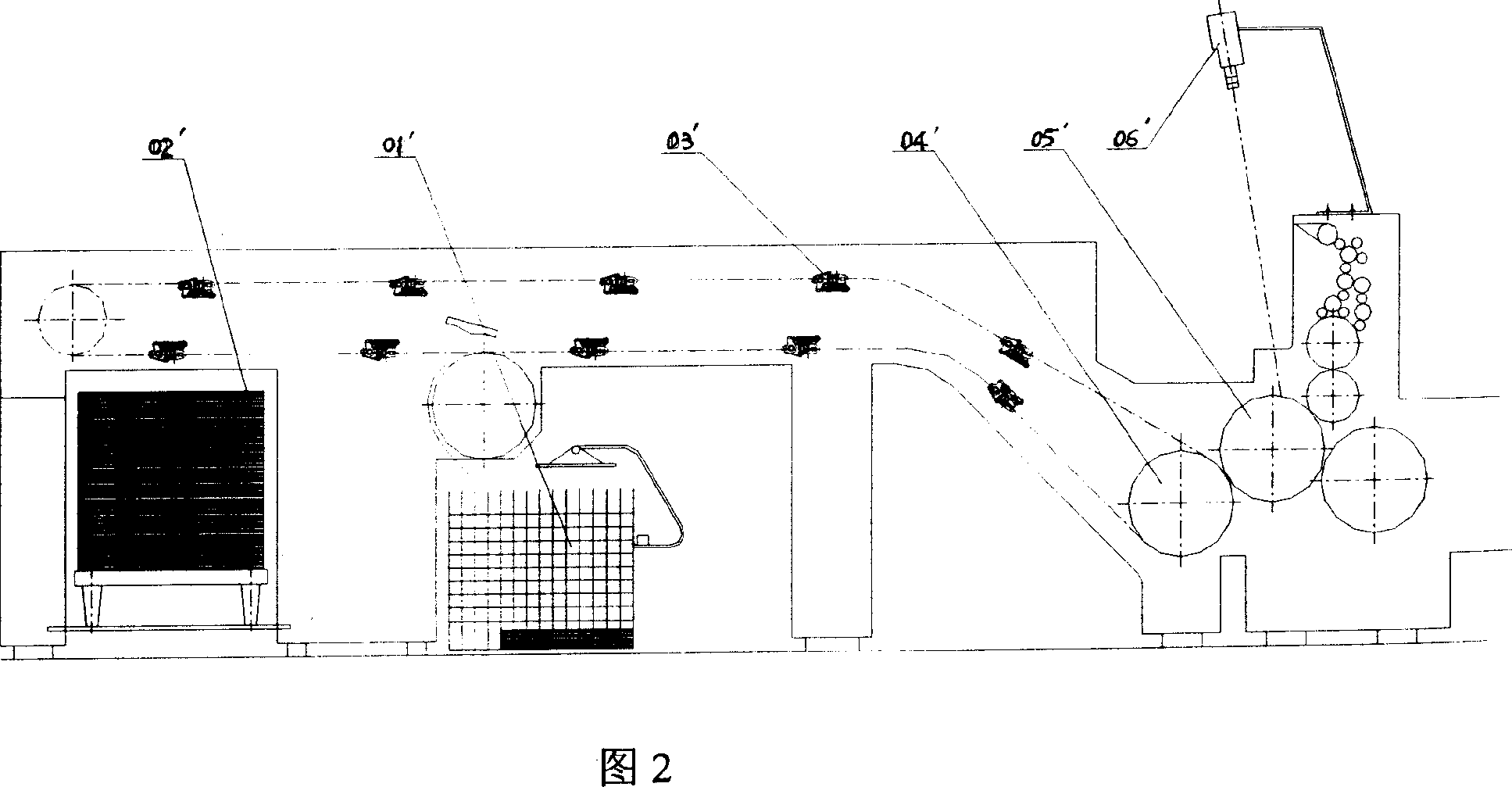

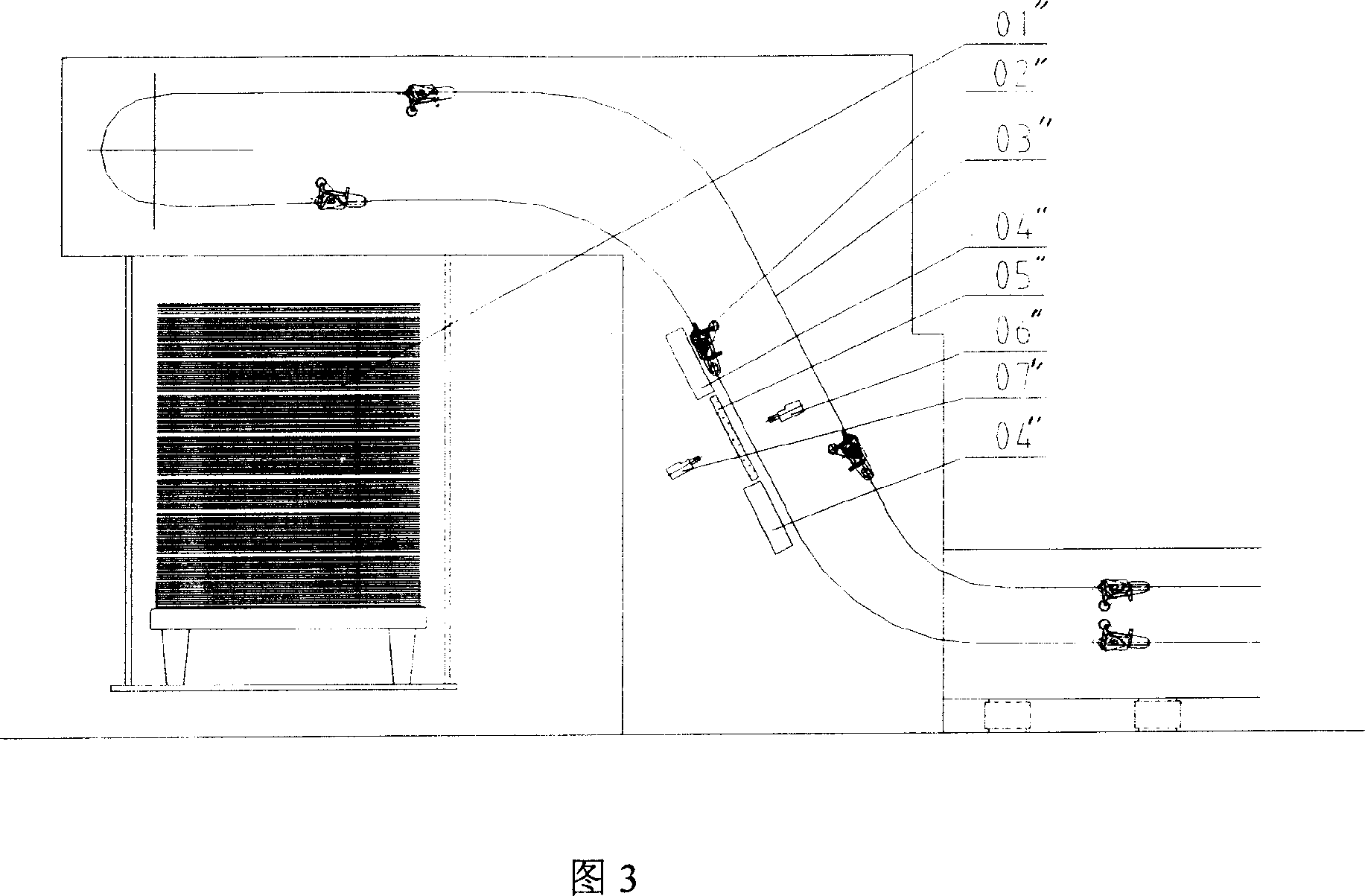

[0034] The present invention is a RMB double-sided offset printing on-line detection good second printed product automatic separation and delivery device, as shown in Figure 4 the improved online detection schematic diagram of the banknote printing offset printing machine of the present invention, a small machine side 01 is installed in the original paper delivery machine side 03 And the detection rollers 09, 10, delivery roller 07 and delivery sprockets 05, 06, 12 on the small machine side 01, etc., complete the installation of the online detection system, and set the blowing pressure paper on the surface of the detection roller close to the detection point device to ensure that the printed matter is close to the surface of the cylinder and improve the accuracy of detection.

[0035] On the premise of keeping the total length of the banknote printing offset printing machine unchanged, an online detection roller and a second delivery bin are added to the original banknote print...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap