Sealing device for machines for thermal treatment of yarns

A technology of sealing head and fiber, applied in the field of textile industry, can solve the problem of no longer use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

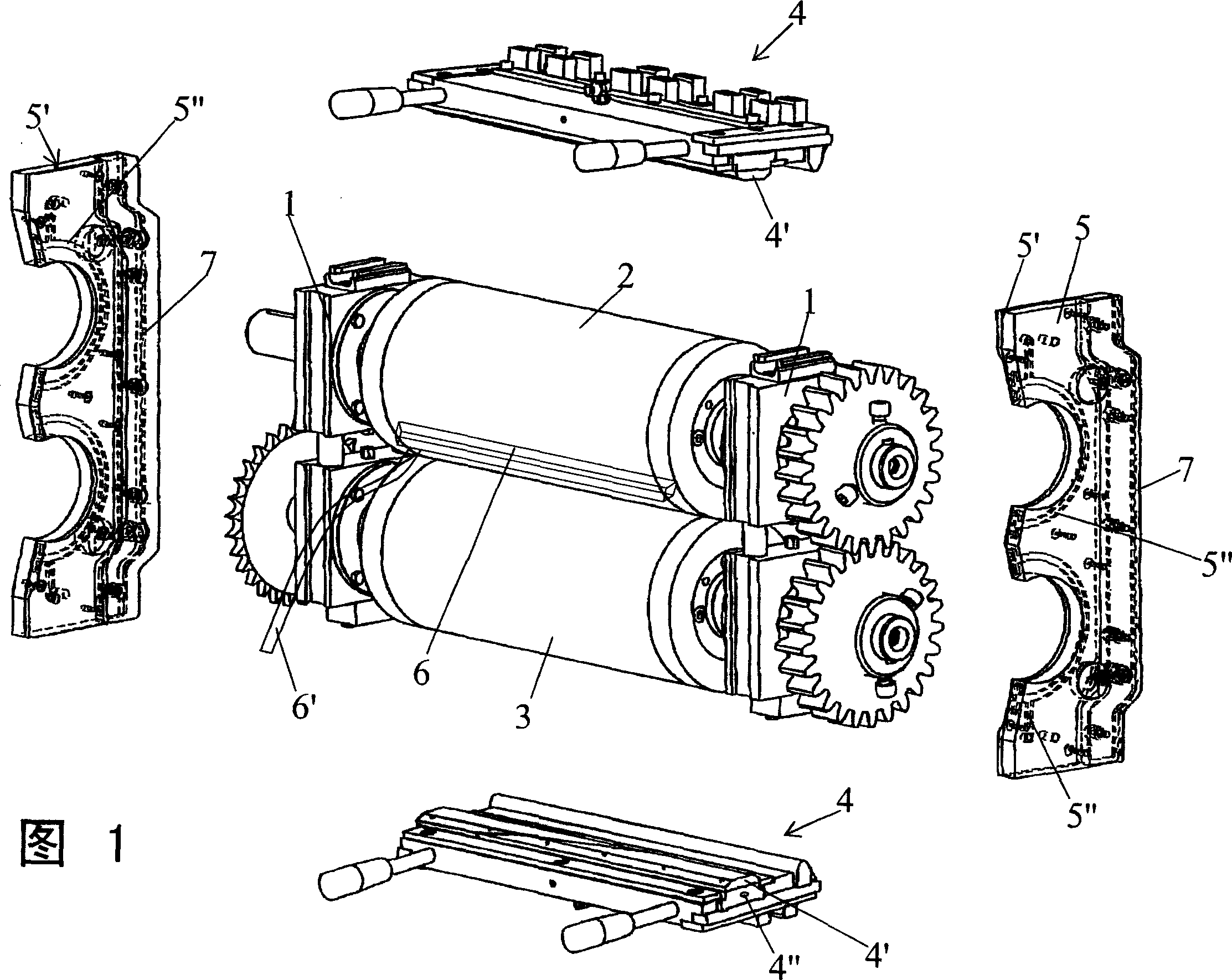

[0016] Figure 1 shows by way of example a sealing head for a fiber heat treatment machine, which mainly includes: a frame 1, which is fixed to a pressurized chamber (not shown) traversed by a conveyor belt (not shown); a pair of upper and lower Superposed horizontal rollers 2 and 3, which push against the opposite surfaces of the conveyor belt; sealing means 4 and 5, which form a sealed closed cavity between the rollers 2, 3 and the frame 1 . At least one horizontal roller 2 and the sealing means 4 and 5 are connected to actuators (not shown in detail) for corresponding movements. The frame 1 , which does not form part of the invention, is only represented by two transverse uprights, which serve to receive the rollers 2 and 3 .

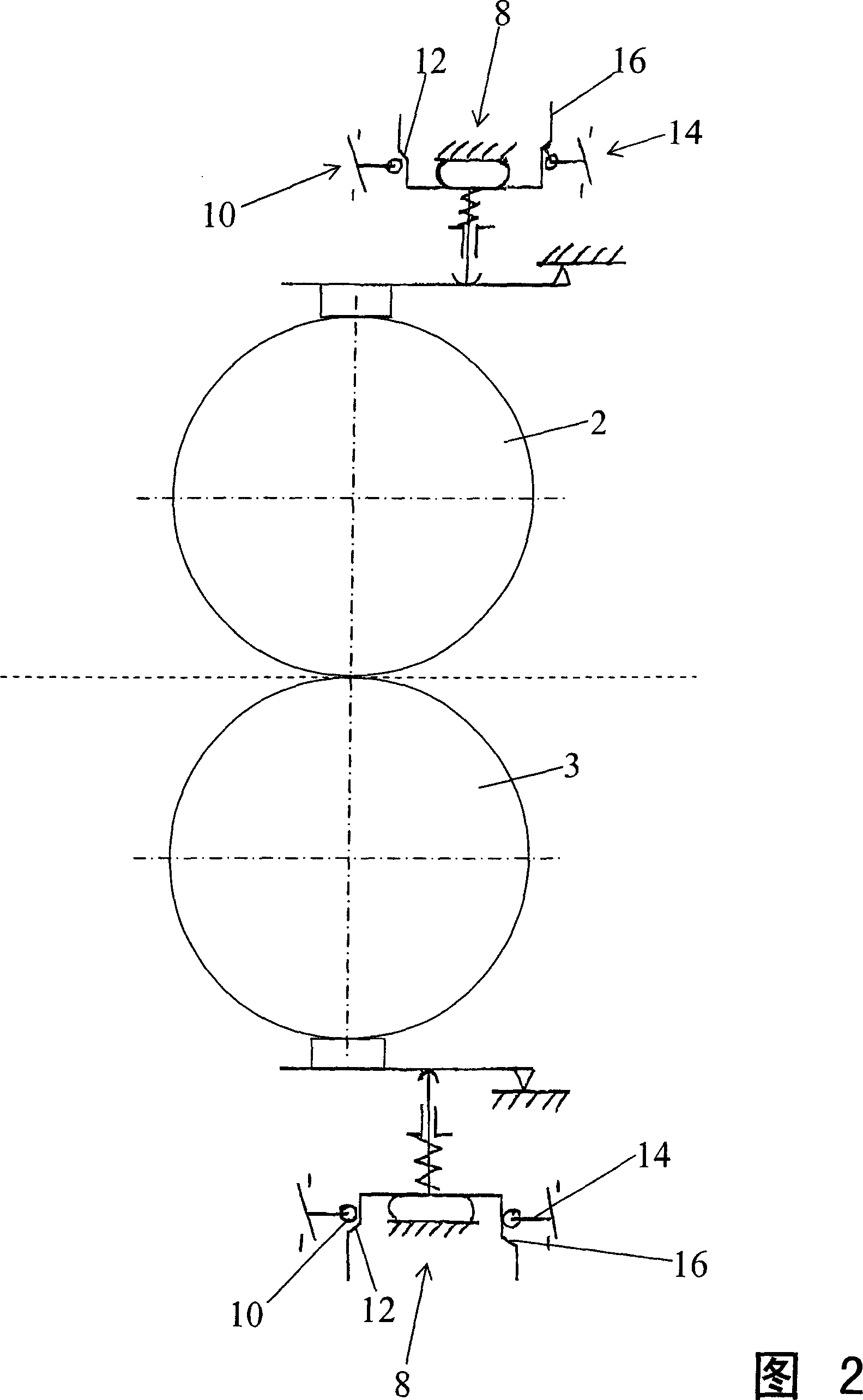

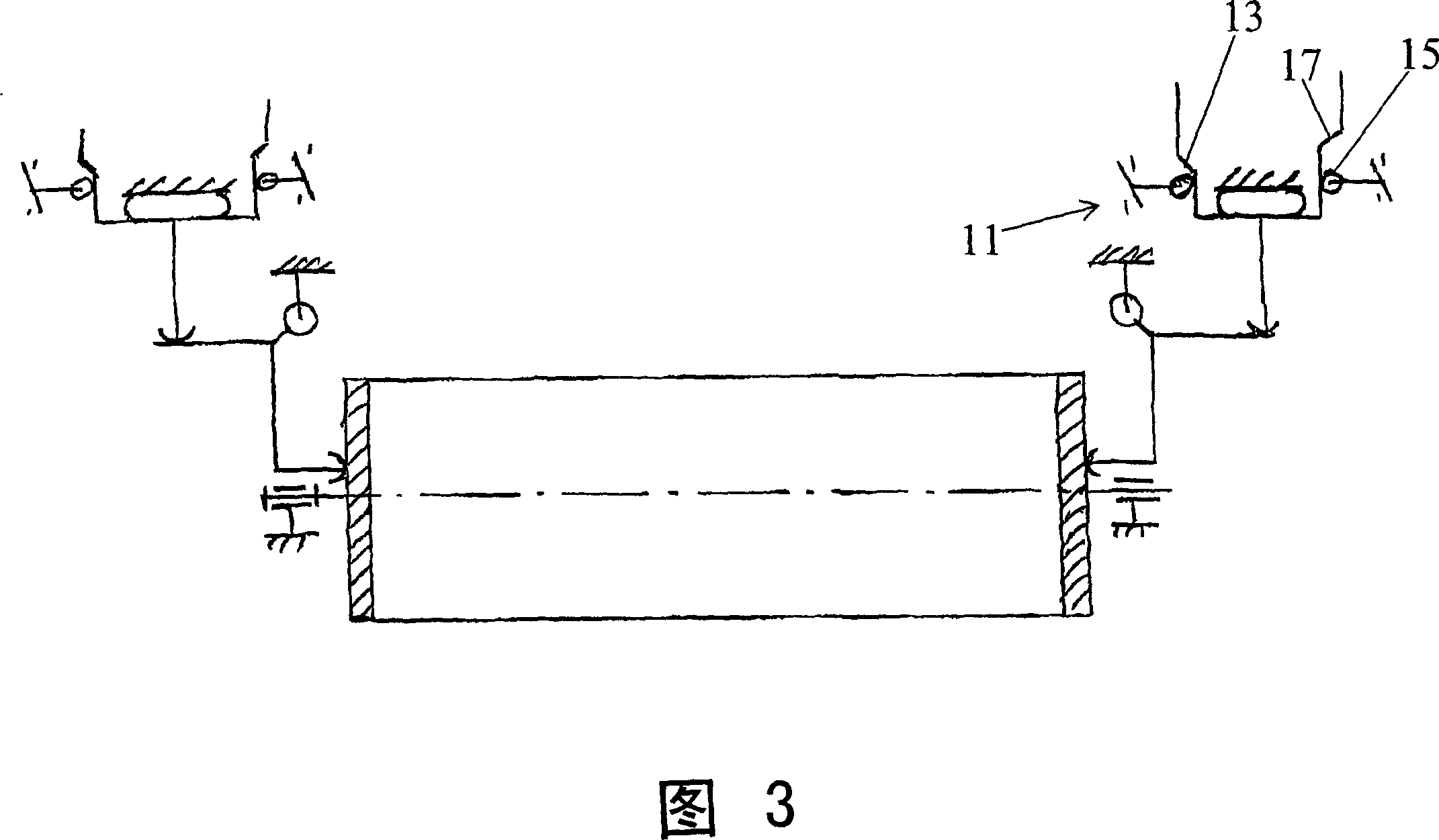

[0017] Furthermore, as shown in FIGS. 2 and 3 , the sealing means 4 and 5 are applied under pressure on the respective surfaces of the rollers 2 and 3 by means of actuators 8 and 9 comprising cylinders. Said cylinders act on the one hand on the seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com