Support

A component and body technology, applied in the direction of shock absorber, shock absorber, non-rotational vibration suppression, etc., can solve the problem of preventing abnormal sound, achieve the effect of preventing abnormal sound and improving the effect of preventing abnormal sound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

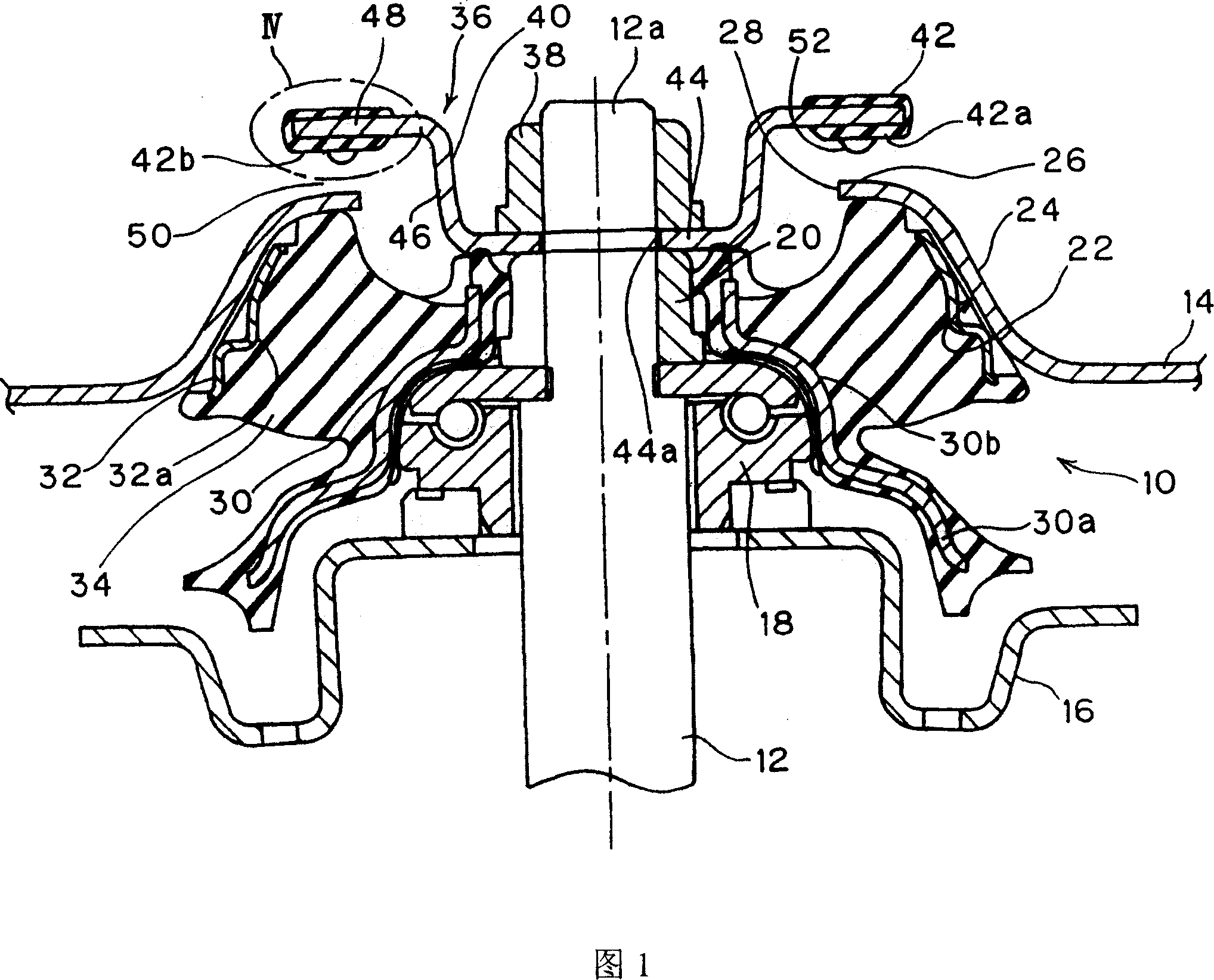

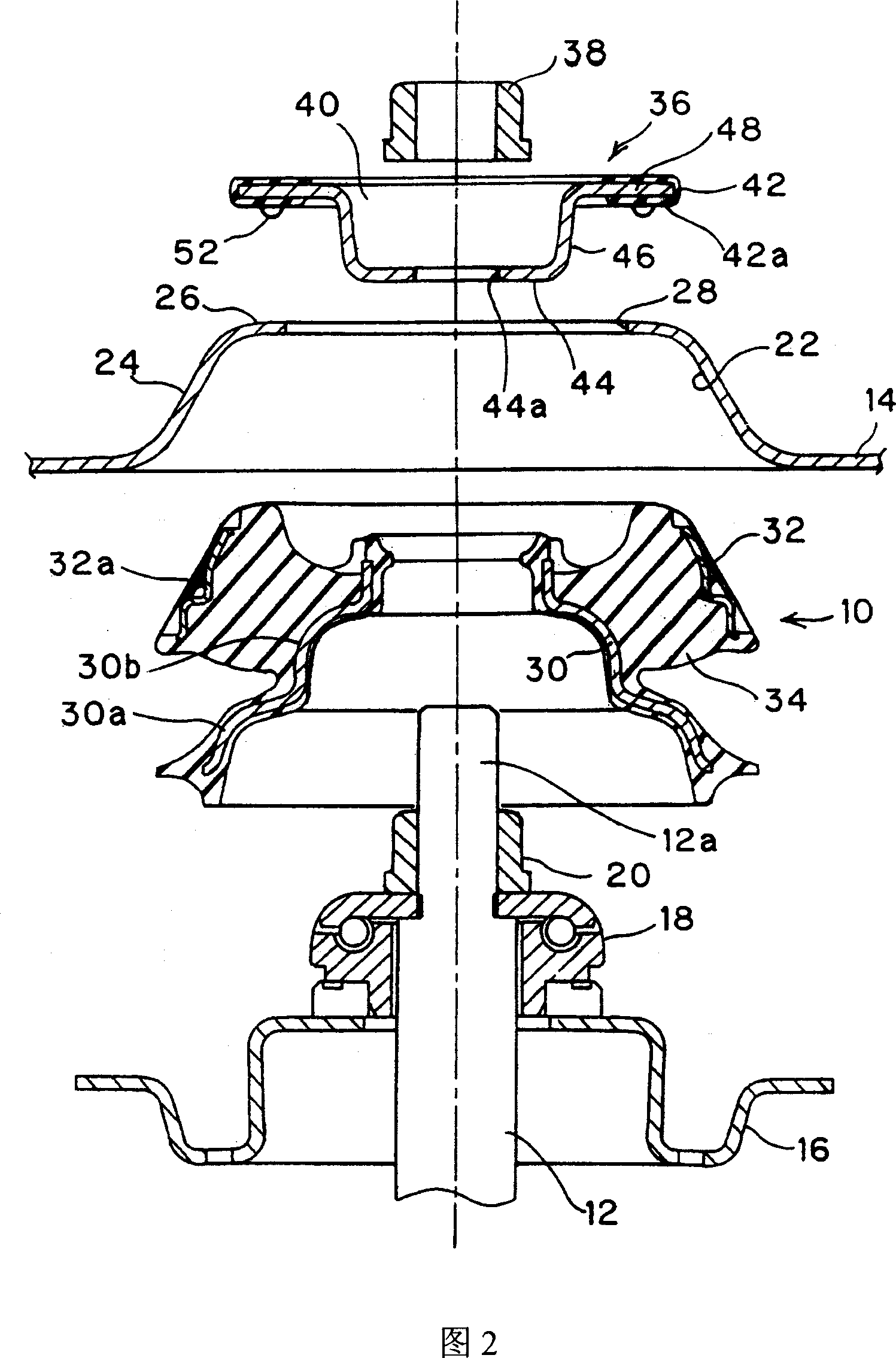

[0055] FIG. 1 is a sectional view showing a state in which a bracket 10 according to a first embodiment of the present invention is mounted on a vehicle, and FIG. 2 is an exploded view thereof.

[0056] In the figure, 12 is a piston rod of a shock absorber, 14 is a vehicle body, 16 is a spring seat supporting the upper end of the coil spring, and 18 is a bearing fixed to the upper end 12a of the piston rod by a nut 20 .

[0057] In the plate-shaped vehicle body 14, there is provided a recess 22 that is recessed upward and opened downward in a convex shape. The side wall portion 24 of the recess 22 is formed in a conical cylindrical shape whose diameter becomes smaller as it goes upward, and a circular opening portion 28 is provided in the upper wall portion 26 . The upper wall portion 26 extends radially inward from the upper end of the side wall portion 24, and is formed in the shape of a ring plate by providing an opening 28 inside, and the upper end portion 12a of the pisto...

no. 2 Embodiment

[0075] Next, a bracket 10A of a second embodiment will be described with reference to FIGS. 6 to 10 . The structure of the stopper rubber part 42 of the second embodiment is different from that of the above-mentioned first embodiment. The structure other than the stopper rubber part is the same as that of the first embodiment, and the same symbols are assigned to the same parts, and the description thereof will be omitted.

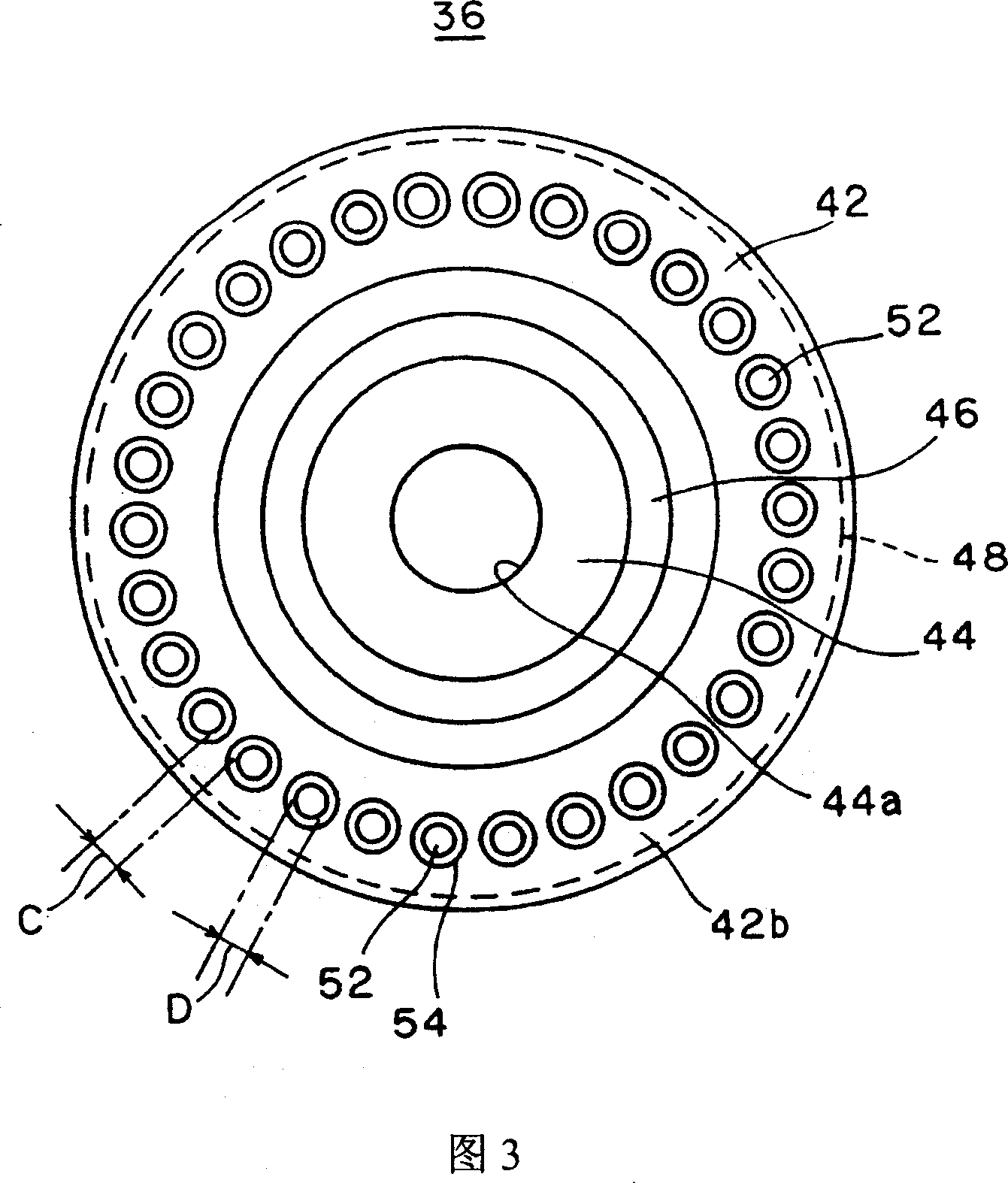

[0076] As shown in Figures 6 to 8, in this embodiment, on the lower surface 42b of the stopper rubber part 42, the plurality of spherical crown protrusions 52 are arranged at equal intervals along the entire circumference of the lower surface 42b to form a double inner and outer structure. ring. Further, the spherical crown protrusions 52 are arranged in an inner circular annular row 56 and an outer circular annular row 58 which are different from each other in the circumferential direction. That is, in the inner annular row 56 and the outer annular row ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com