A gleeble sample loading tool suitable for samples whose radius is smaller than that of graphite flakes and tantalum flakes

A graphite sheet and radius technology, applied in the field of Gleeble sample loading tools, can solve the problems of contact between the tantalum sheet and the indenter, the sample is not centered, and difficult to use, so as to improve accuracy and facilitate sample loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention is described further as follows:

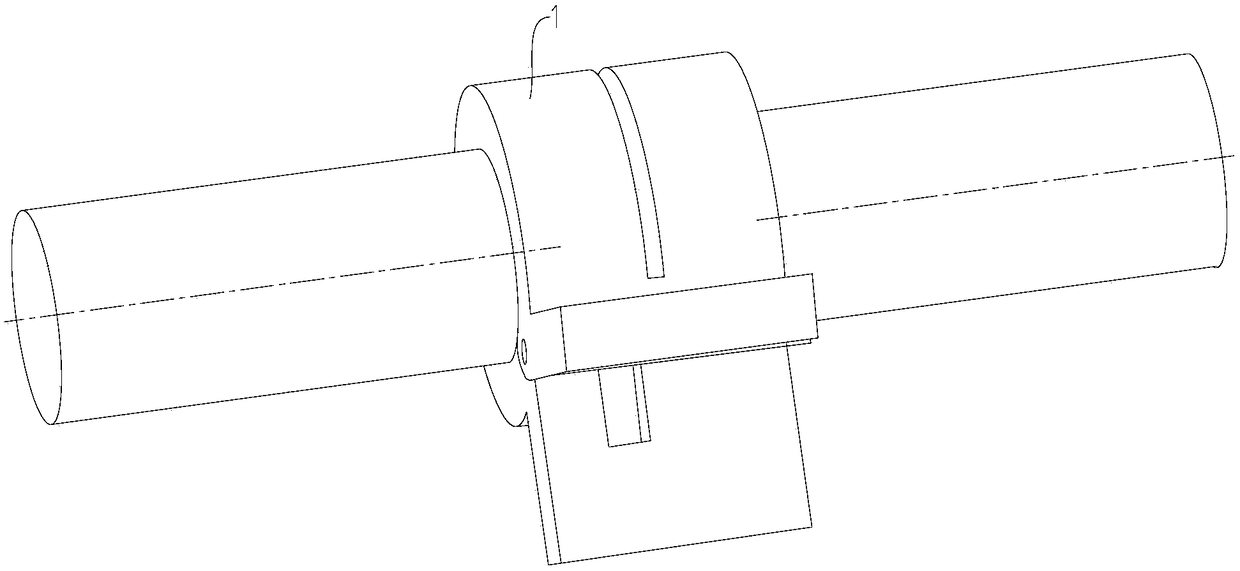

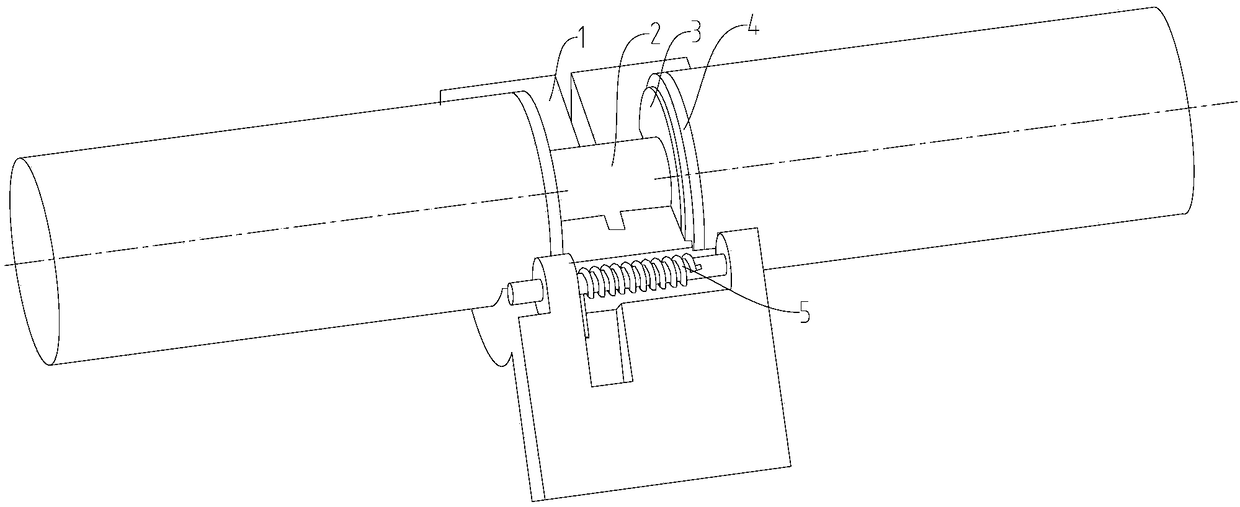

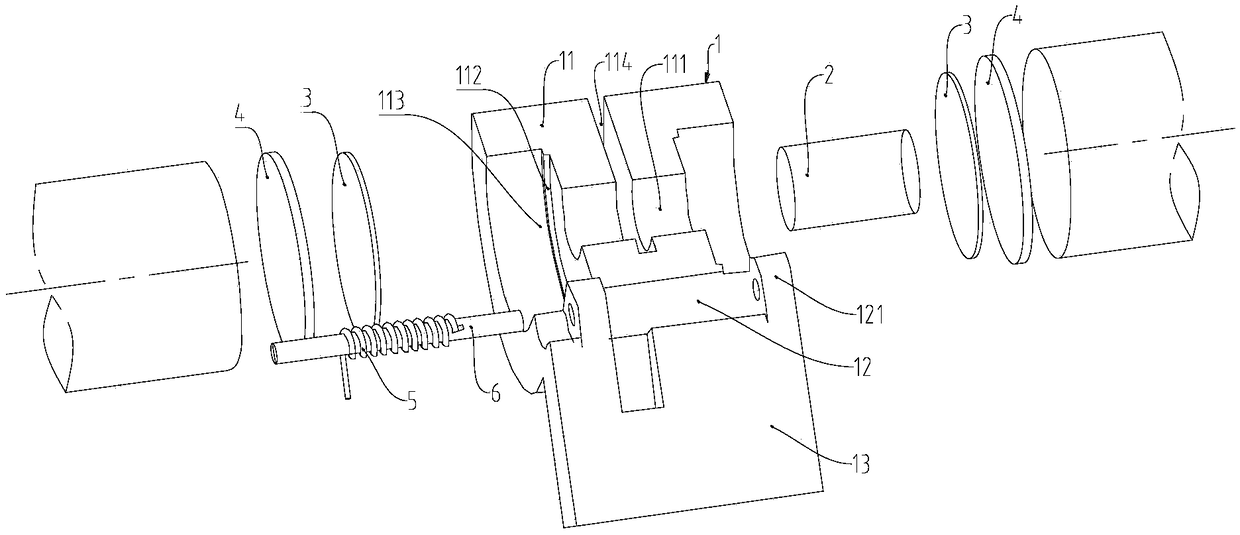

[0018] A Gleeble sample loading tool suitable for samples whose radius is smaller than that of graphite flakes and tantalum flakes, such as figure 1 , figure 2 and image 3 As shown, two grippers 1 are included. The gripper 1 includes a clamping part 11, a connecting part 12 and a handle part 13. One end of the connecting part 12 is connected to the handle part 13, and the other end is connected to the clamping part 11;

[0019] The clamping part 11 is provided with a semicircular through groove 111, and the opening of the semicircular through groove 111 on the connecting part 12 of the two grippers 1 is relatively surrounded to form a sample installation hole; in the clamping part 11 Both ends of the semicircular first stepped groove 112 and the second stepped groove 113 are provided; the first stepped groove 112 and the second stepped groove 113 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com