Vacuum switchgear

A technology of vacuum switch and vacuum container, which is applied in electrical switches, high-voltage/high-current switches, high-voltage air circuit breakers, etc., can solve problems such as increasing costs and complex detection circuits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

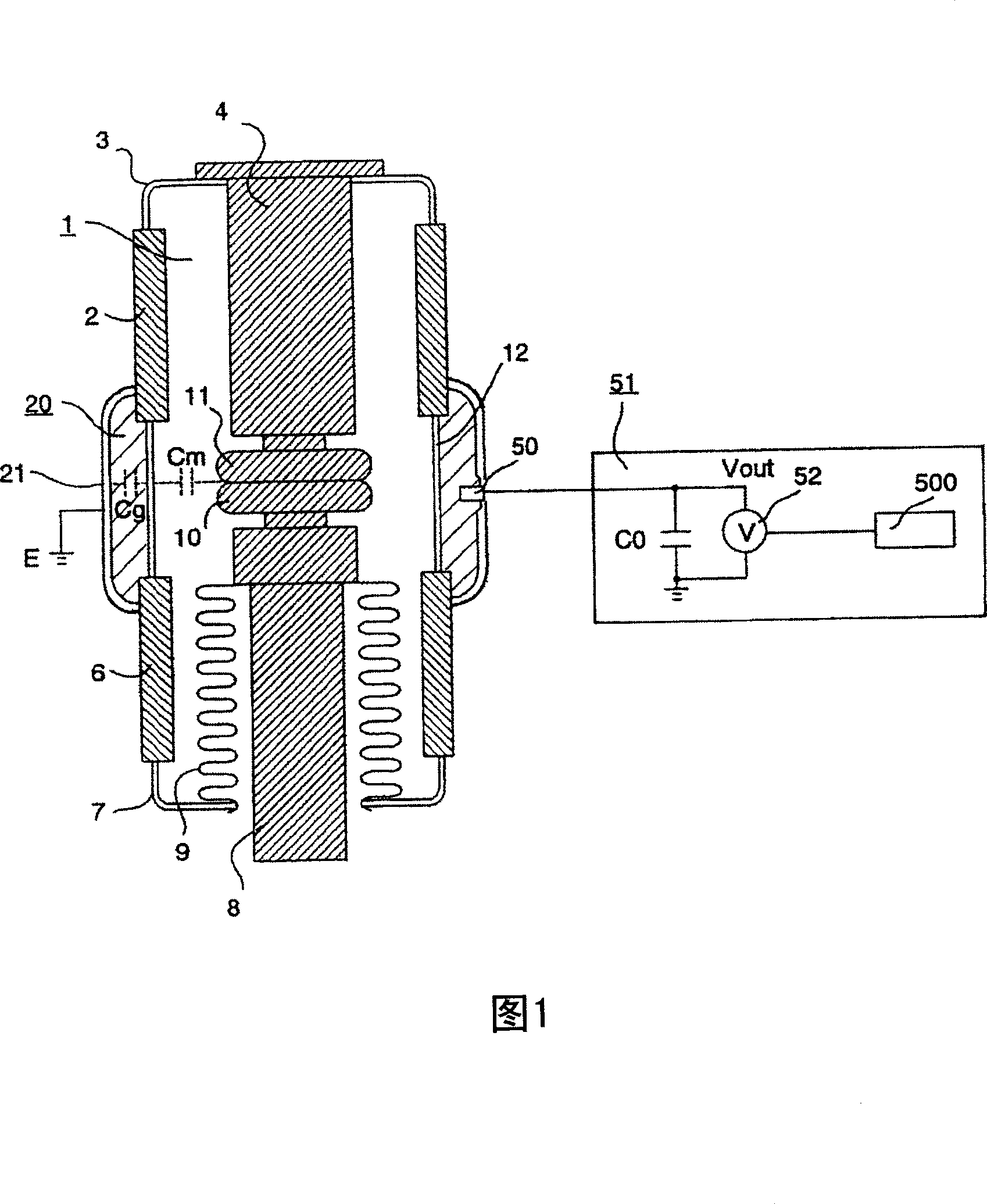

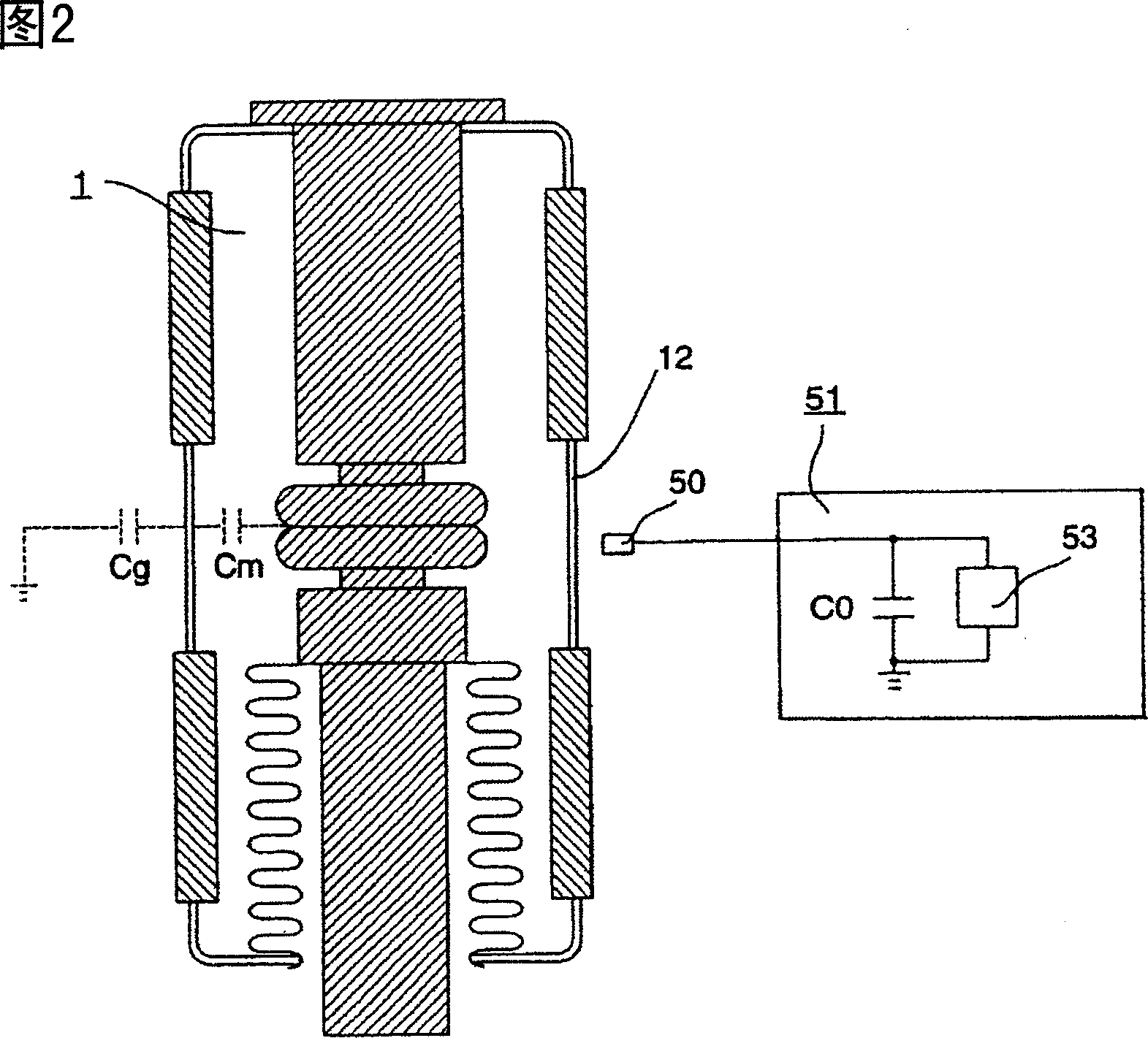

Embodiment 1

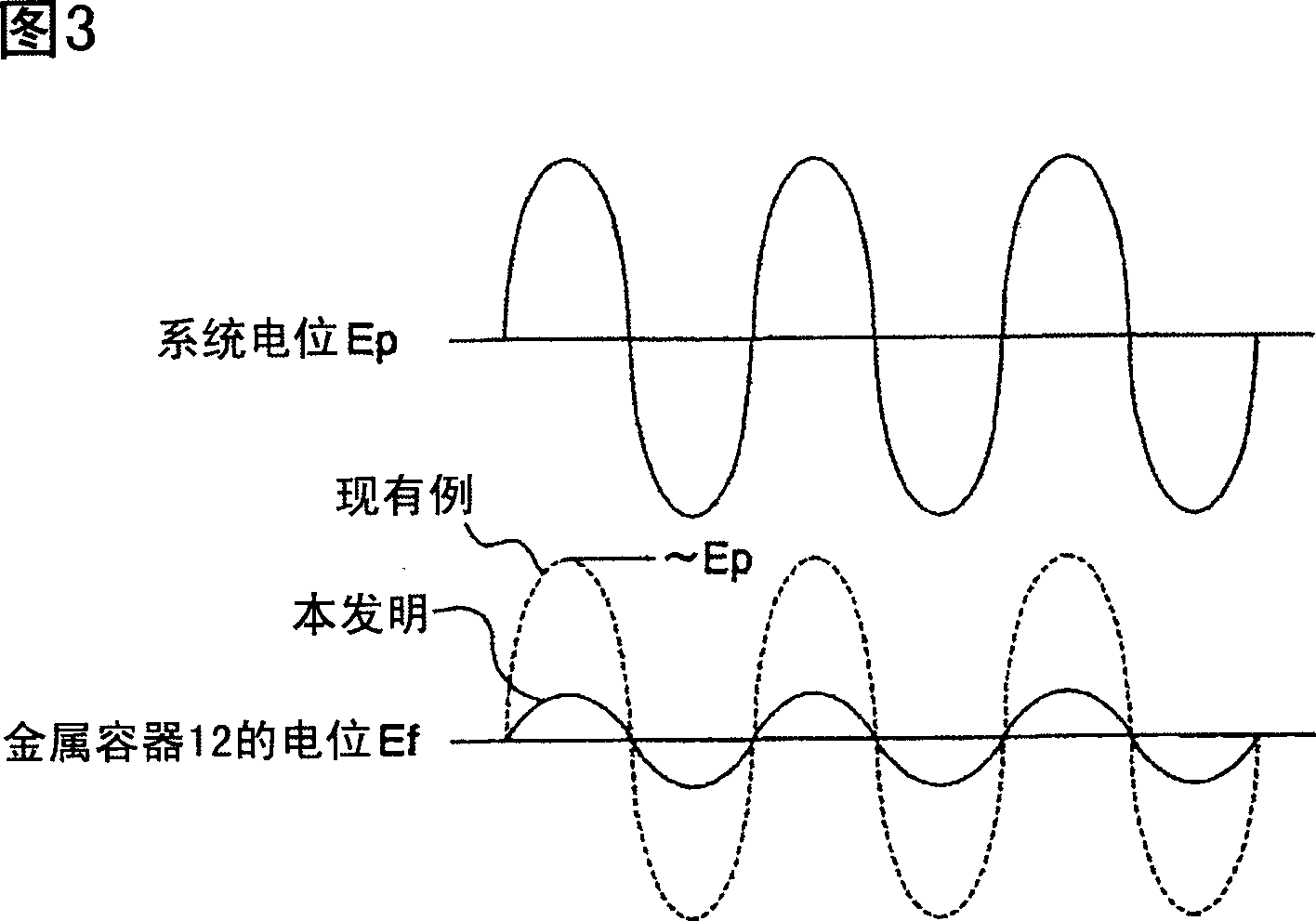

[0036] Embodiment 1 and Embodiment 2 have one thing in common, that is, the arc generated between the electrodes may touch the metal container 12 during the switching on and off operations, and the potential Ef of the metal container 12 at this time is equal to the system potential Ep. The occurrence of this phenomenon has nothing to do with the tightness of the vacuum pressure, so the diagnostic results when the action command is issued should be excluded.

[0037] Next, a third embodiment of the present invention will be described with reference to FIG. 10 .

[0038] The vacuum switchgear 100 has a vacuum tube 101 having cut-off and disconnection functions, and a vacuum tube 102 for grounding switching, both of which are cast by an insulator 20 having a grounded conductive coating 21 around it. Since the vacuum tube 101 has a disconnection function, it is desirable to exhibit a vacuum pressure diagnosis function while ensuring the safety of maintenance and repair personnel. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com