Method for preparing 2,4-di-tert.-butyl phenol alkylating solution

A technology of di-tert-butylphenol alkane and phenol, which is applied in the field of intermediate manufacture of 2.4-di-tert-butylphenol, can solve the problems of low conversion rate, high production cost, and low content of 2.4-di-tert-butylphenol. achieve the effect of increasing the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Add the specified amount of phenol and catalyst activated clay according to the ratio of phenol: activated clay = 1: 0.02, then pass into isobutylene according to the ratio of phenol: activated clay: isobutene = 1: 0.02: 1.22, and control the reaction temperature at 85 ± 1 °C for the alkylation reaction. After passing through the alkenes, keep the reaction for 0.5 hours, and then remove the catalyst by filtration to obtain 24 alkylated liquid, the content of 2.4-di-tert-butylphenol is 85.92% after analysis.

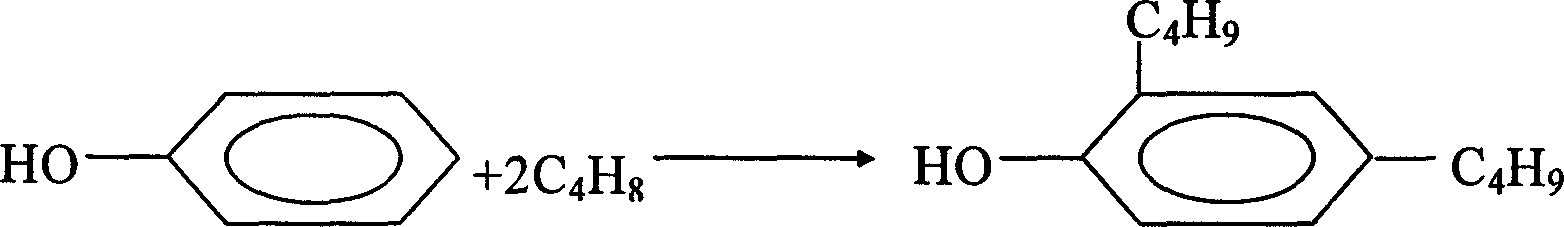

[0015] Described alkylation equation is:

[0016]

Embodiment 2

[0018] Add the specified amount of phenol and catalyst active clay according to the ratio of phenol: activated clay = 1: 0.06, then pass into isobutylene according to the ratio of phenol: activated clay: isobutene = 1: 0.06: 1.15, and control the reaction temperature at 83 ± 1 °C for the alkylation reaction. After passing through the alkenes, keep the reaction for 1.0 hour, and then remove the catalyst by filtration to obtain 24 alkylated liquid, the content of 2.4-di-tert-butylphenol is 86.37% after analysis.

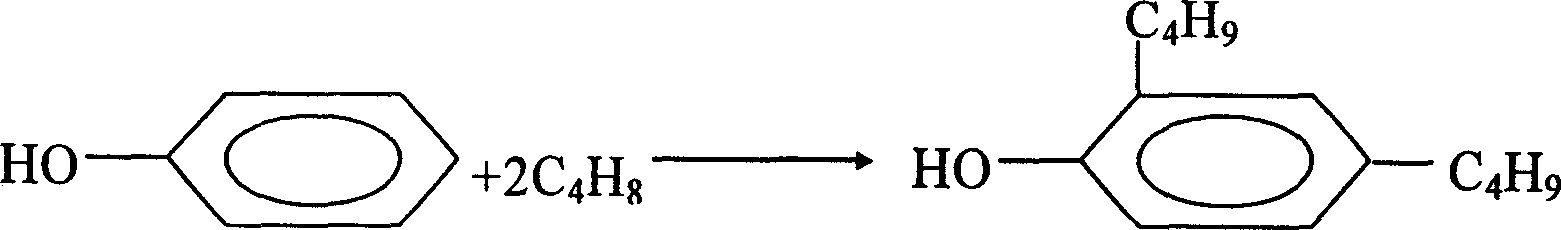

[0019] Described alkylation equation is:

[0020]

Embodiment 3

[0022] Add the specified amount of phenol and catalyst active clay according to the ratio of phenol: activated clay = 1: 0.05, then pass into isobutylene according to the ratio of phenol: activated clay: isobutene = 1: 0.05: 1.19, and control the reaction temperature at 83 ± 1 °C for the alkylation reaction. After passing through the alkenes, keep the reaction for 1.0 hour, and then remove the catalyst by filtration to obtain 24 alkylated liquid, the content of 2.4-di-tert-butylphenol is 87.05% after analysis.

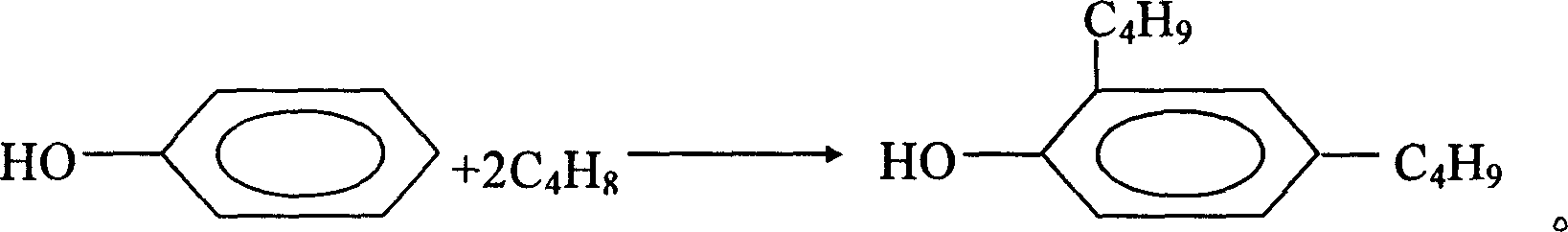

[0023] Described alkylation equation is:

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com