Electrical connector having ground planes

A technology for electrical connectors and grounding plates, which is applied in the direction of connection, two-part connection device, and parts of the connection device. Smooth insertion and removal, full contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described below with reference to FIGS. 1 to 5 of the drawings.

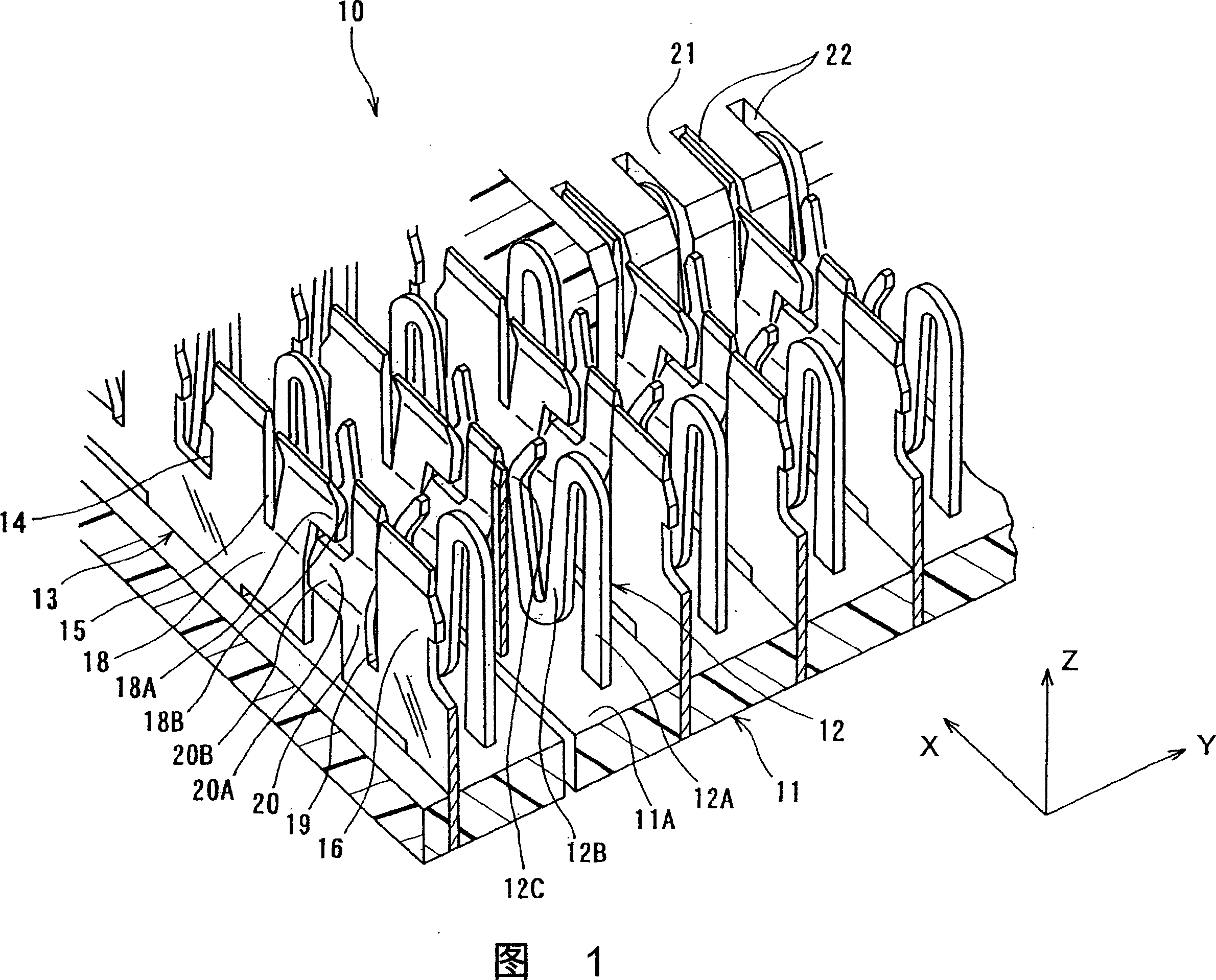

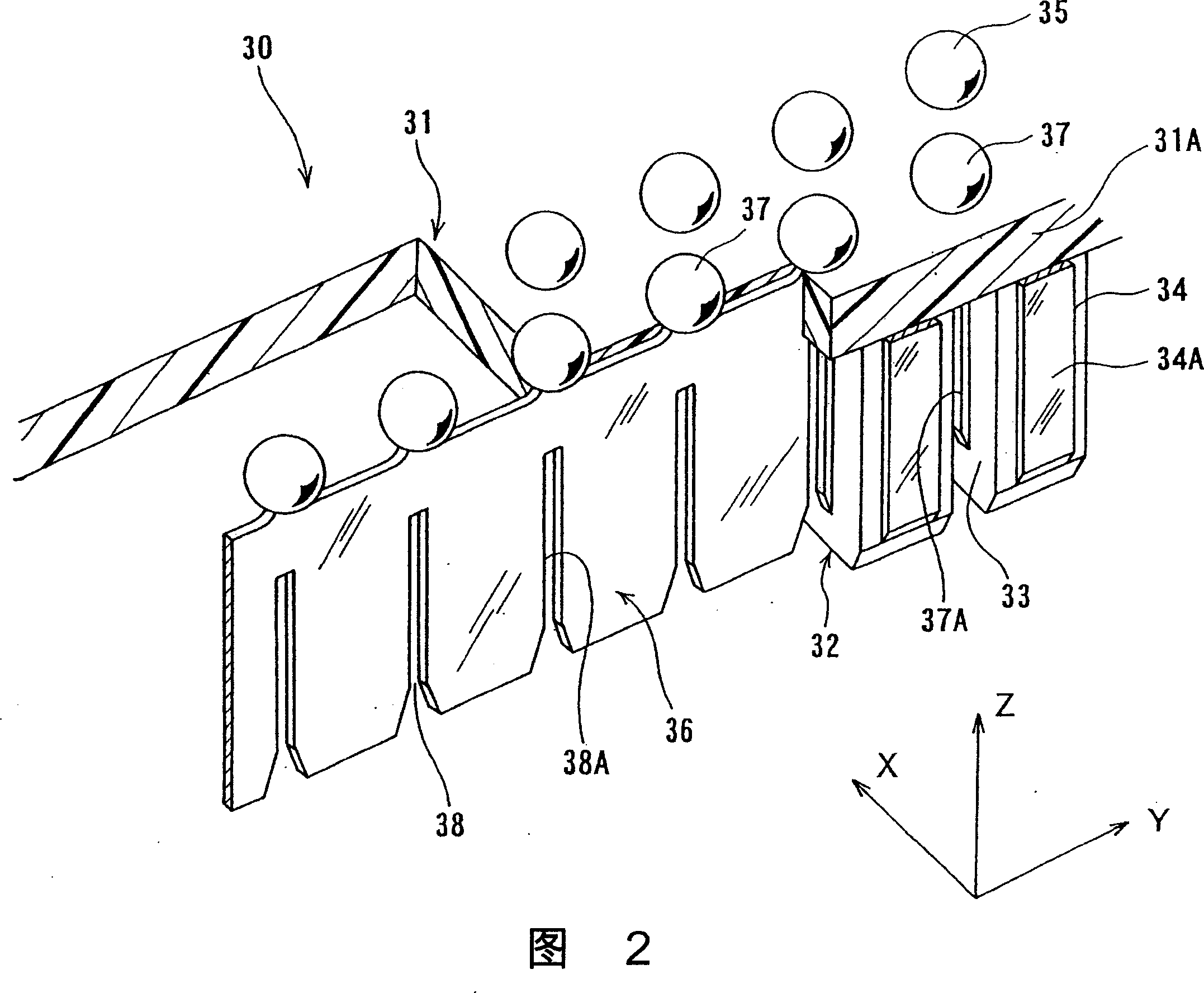

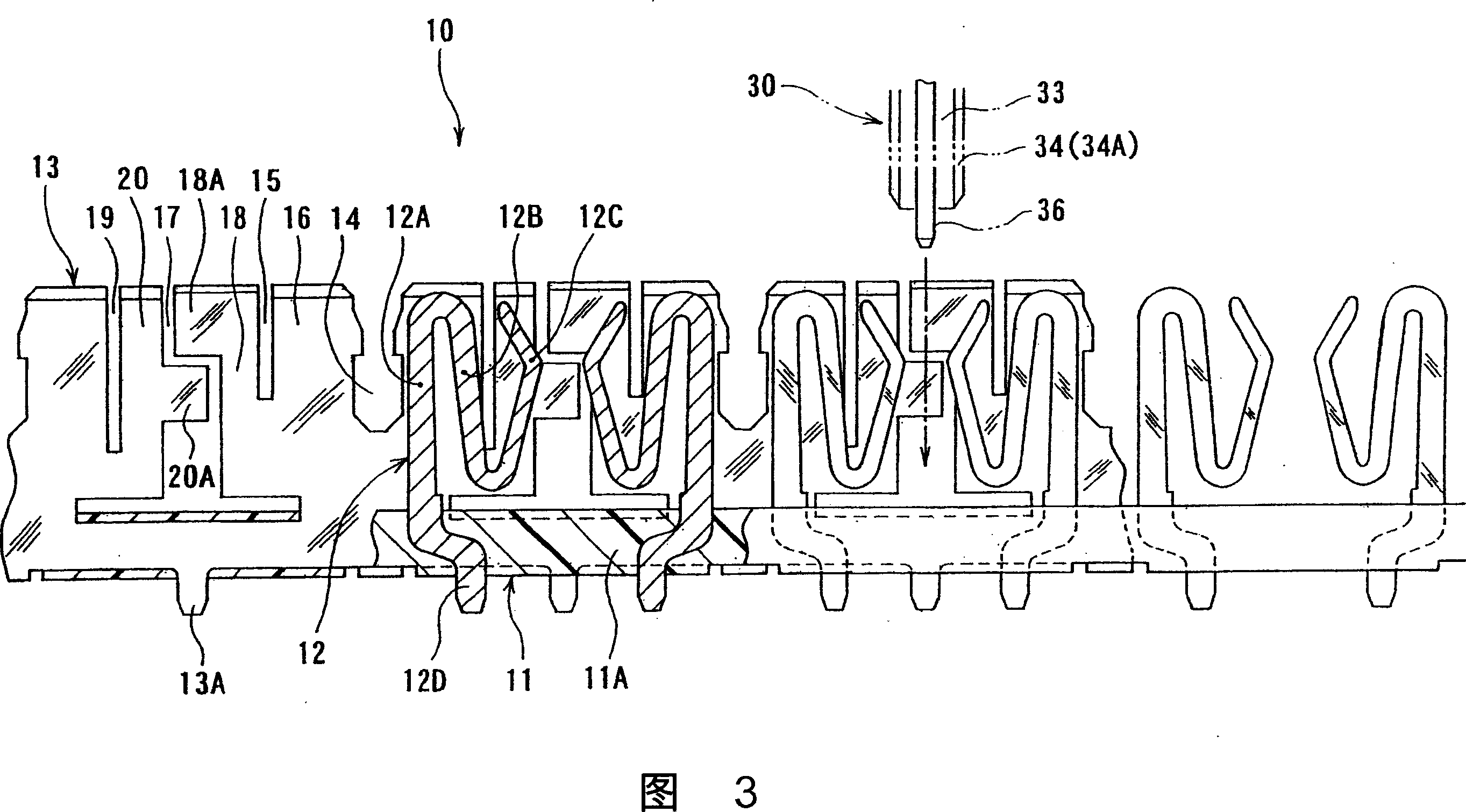

[0028] FIG. 1 shows the connector of the present embodiment, and FIG. 2 shows a mating connector which is fitted and connected to the connector. Both figures are perspective views showing the part of the fitted connection.

[0029] In the connector 10 of the present embodiment shown in FIG. 1 , the signal terminals 12 and the ground plate 13 are supported by a housing 11 made of an electrically insulating material. In the figure, the signal terminals 12 and the ground plates 13 have surfaces substantially parallel to the XZ plane of the three-dimensional space coordinates XYZ, and are alternately arranged at regular intervals in the Y direction.

[0030] As shown in FIGS. 1 and 3 , a plurality of signal terminals 12 located on one XZ plane are formed by applying contour processing to the surface of a metal plate while maintaining a flat surface, and the plate s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com