Electrostatic atomizing device

An electrostatic atomization and electrode technology, which is applied in the direction of electrostatic spraying device, spraying device, liquid spraying equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

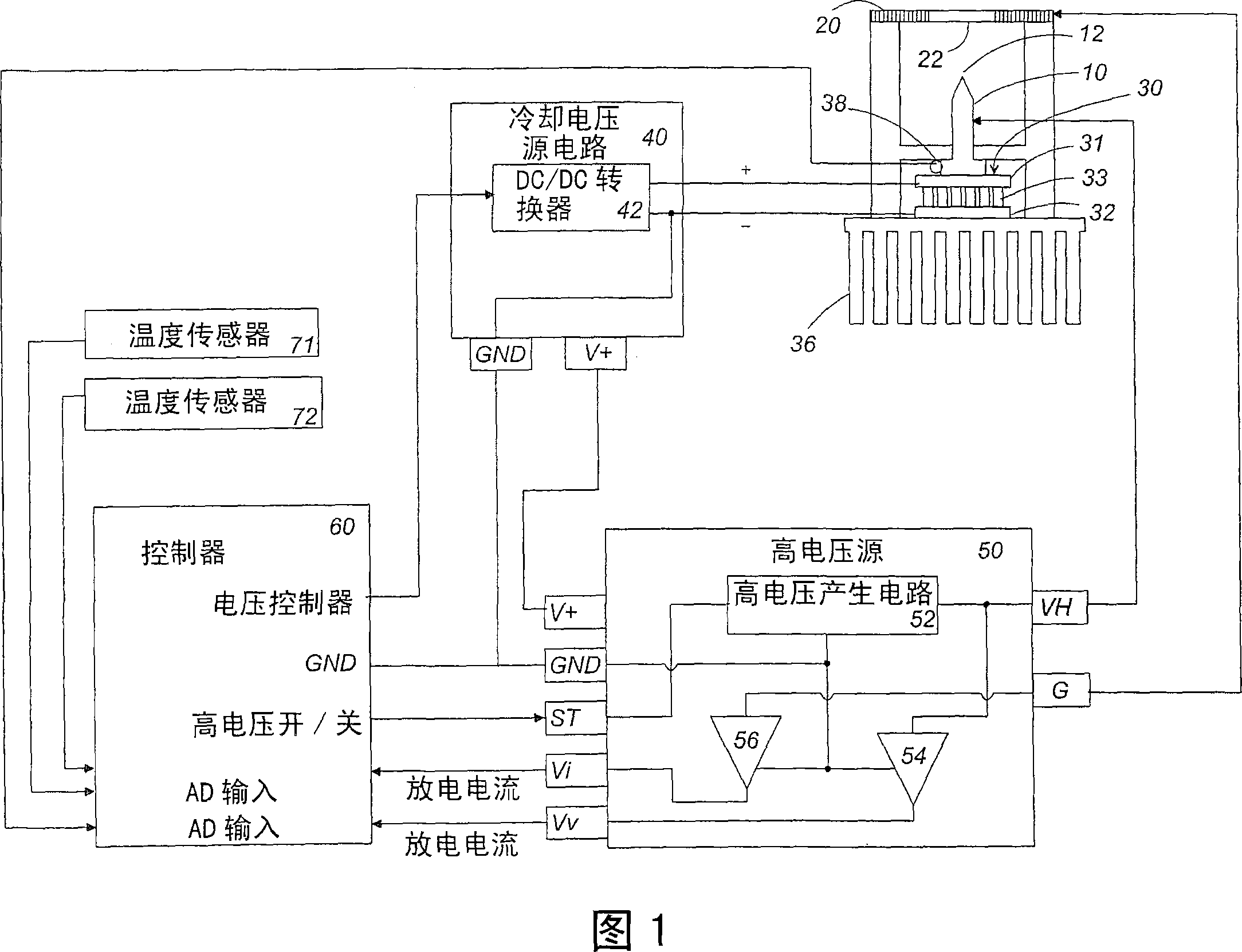

Method used

Image

Examples

no. 2 example

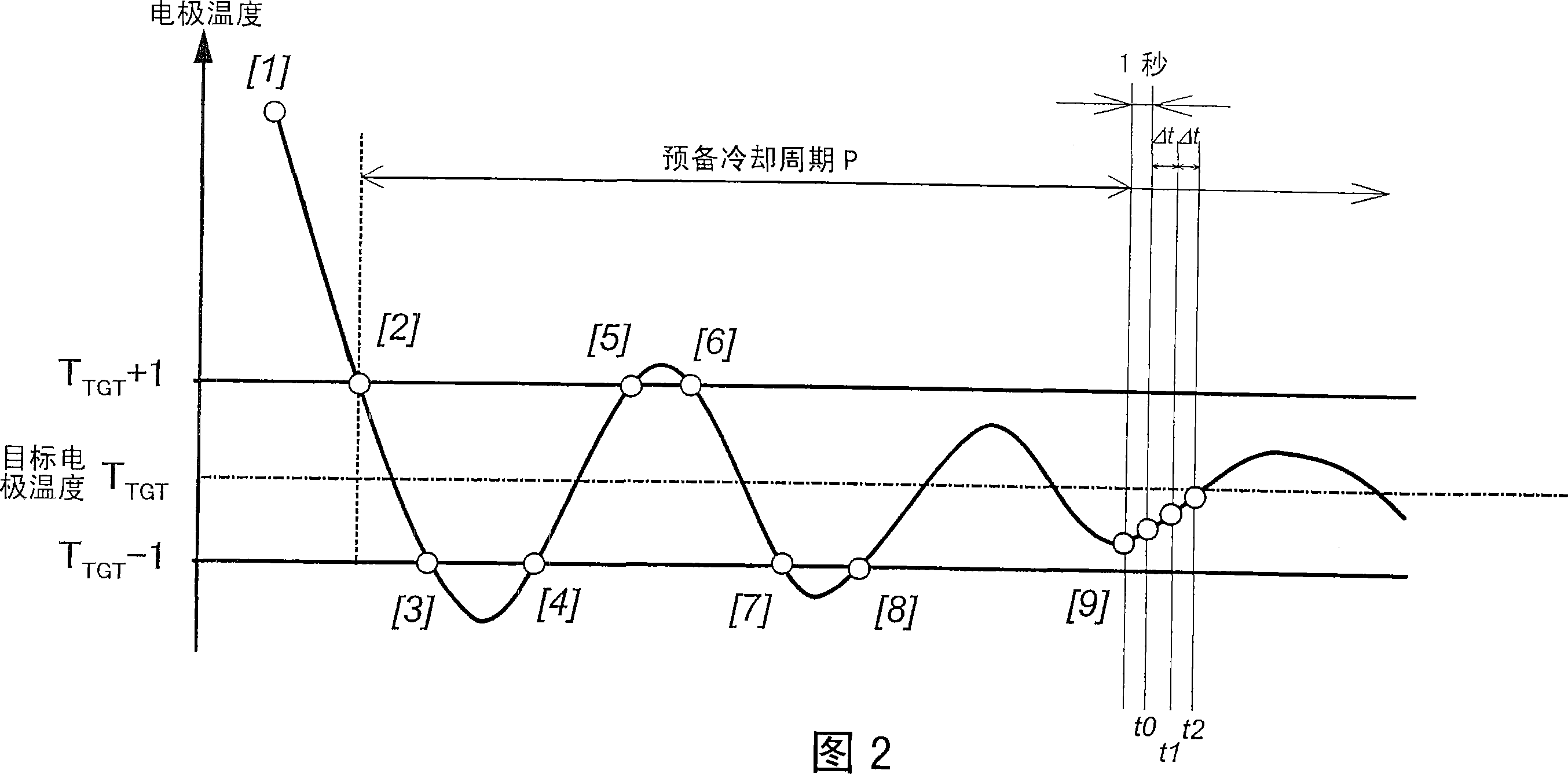

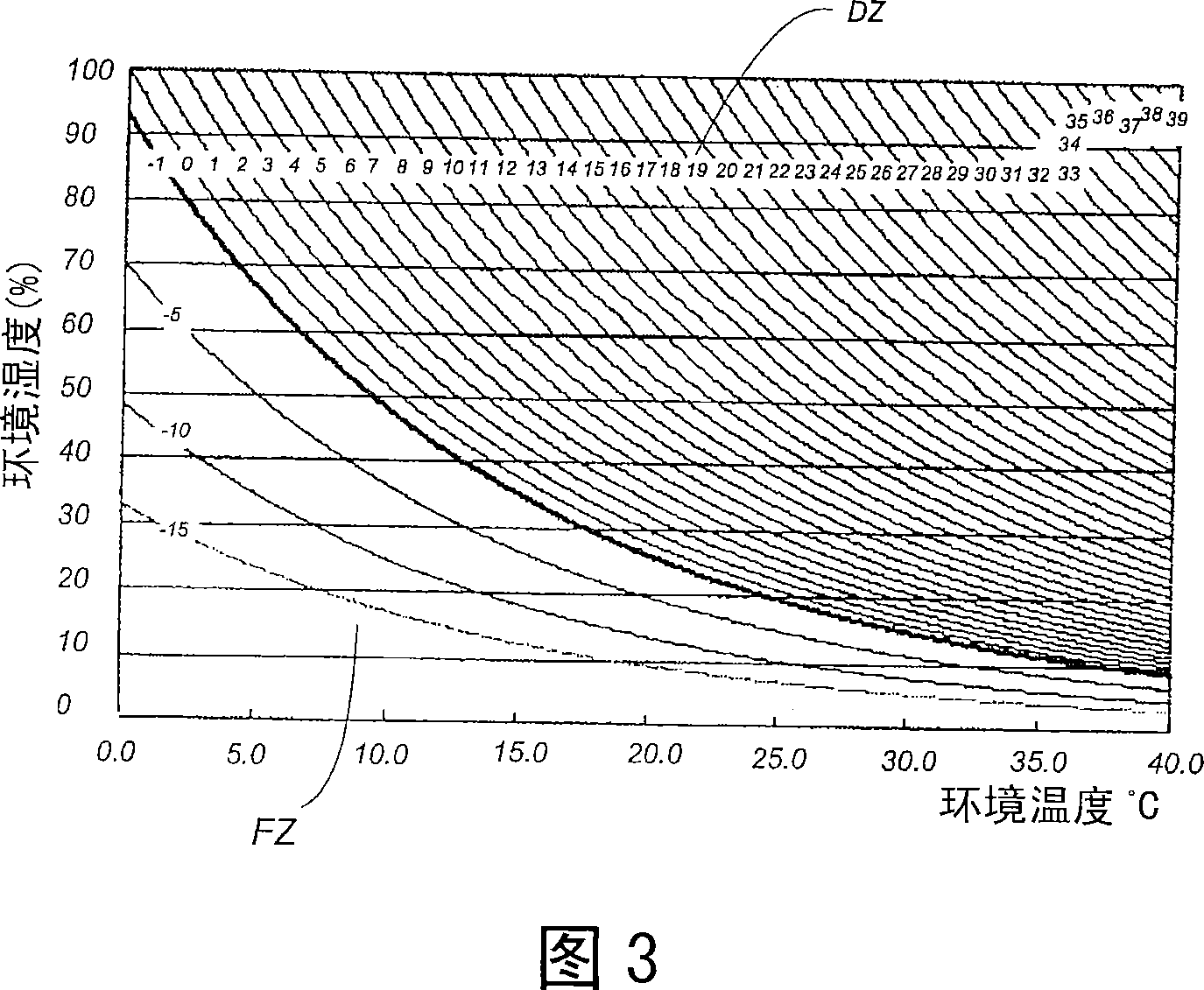

[0095] The electrostatic atomization device according to the second embodiment of the present invention is basically the same as the first embodiment, except that a different scheme is adopted to adjust the temperature of the emitter electrode to the target electrode temperature determined according to the ambient temperature and humidity. Compared to the first embodiment that discloses a PWM control scheme for controlling the Peltier module 30 by the duty cycle D, which is determined by the temperature difference between the electrode temperature and the target electrode temperature shown in Table 2 ΔT determination, this embodiment discloses a control scheme for continuously changing the duty cycle D to cool the emitter electrode to a target electrode temperature determined by ambient temperature and humidity, except when the electrostatic atomizing device is activated.

[0096] The controller 60 reads the ambient temperature and humidity to obtain the target electrode temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com