Observing device and fluorescent light observing device

An observation device and fluorescence technology, applied in optics, optical components, instruments, etc., can solve problems such as too small numerical aperture, difficult lighting, difficult zooming, etc., and achieve the effect of ensuring space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

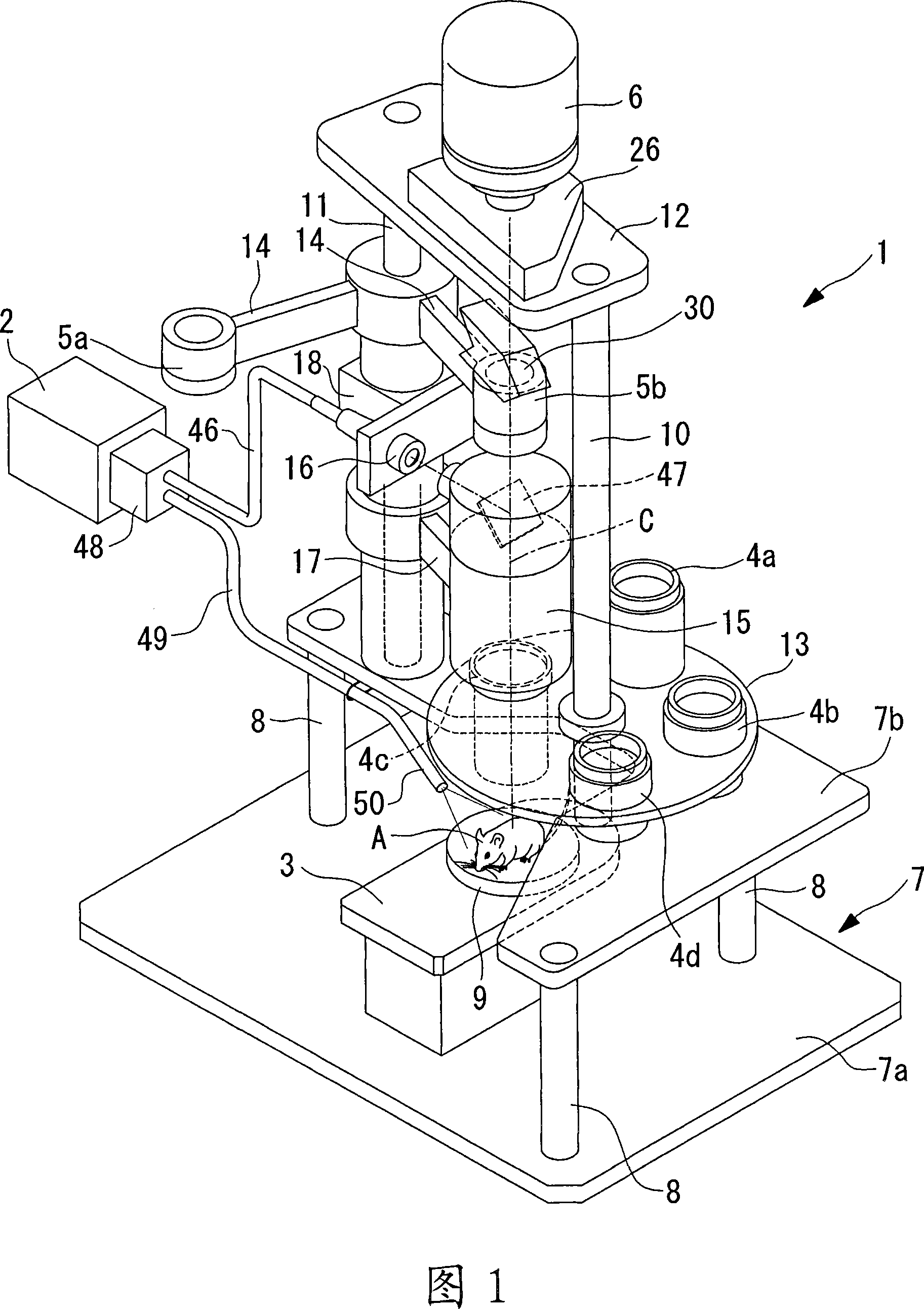

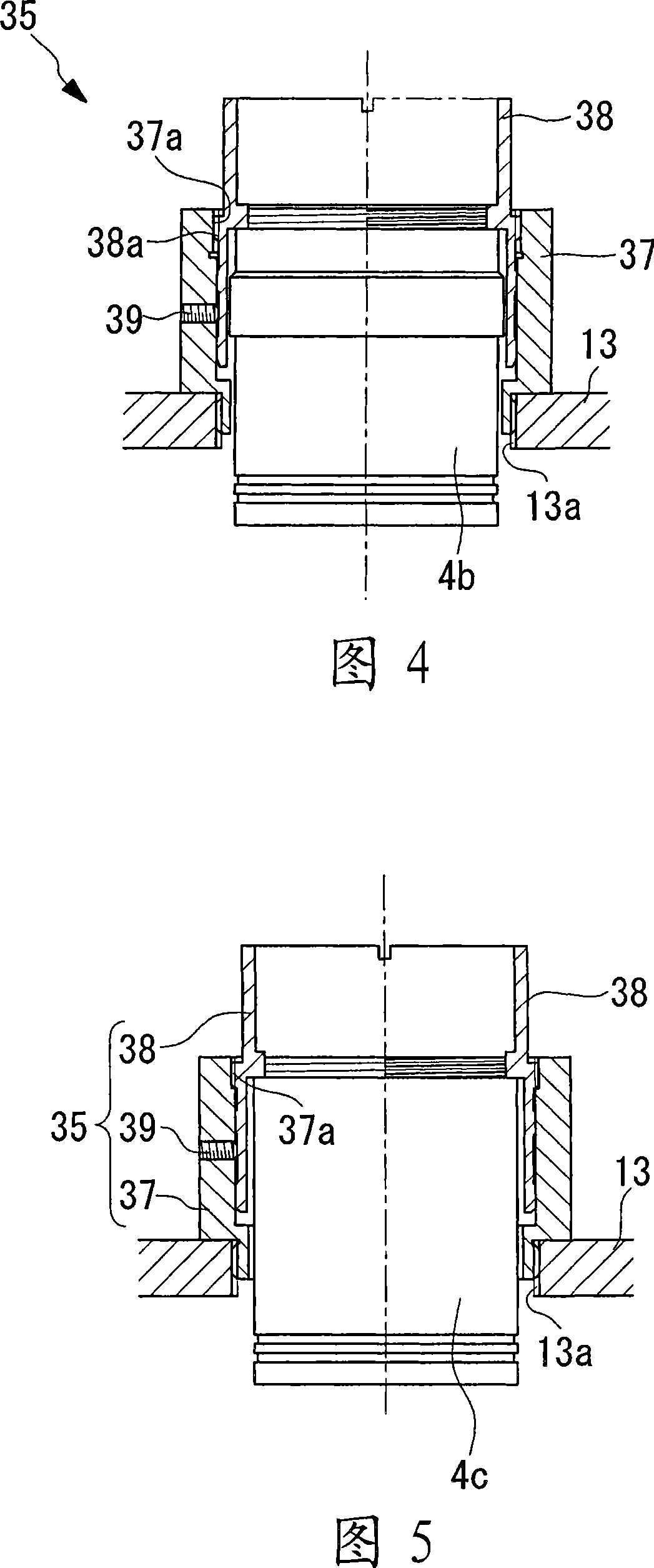

[0106] Hereinafter, a microscope observation device according to a first embodiment of the present invention will be described with reference to FIGS. 1 to 15 .

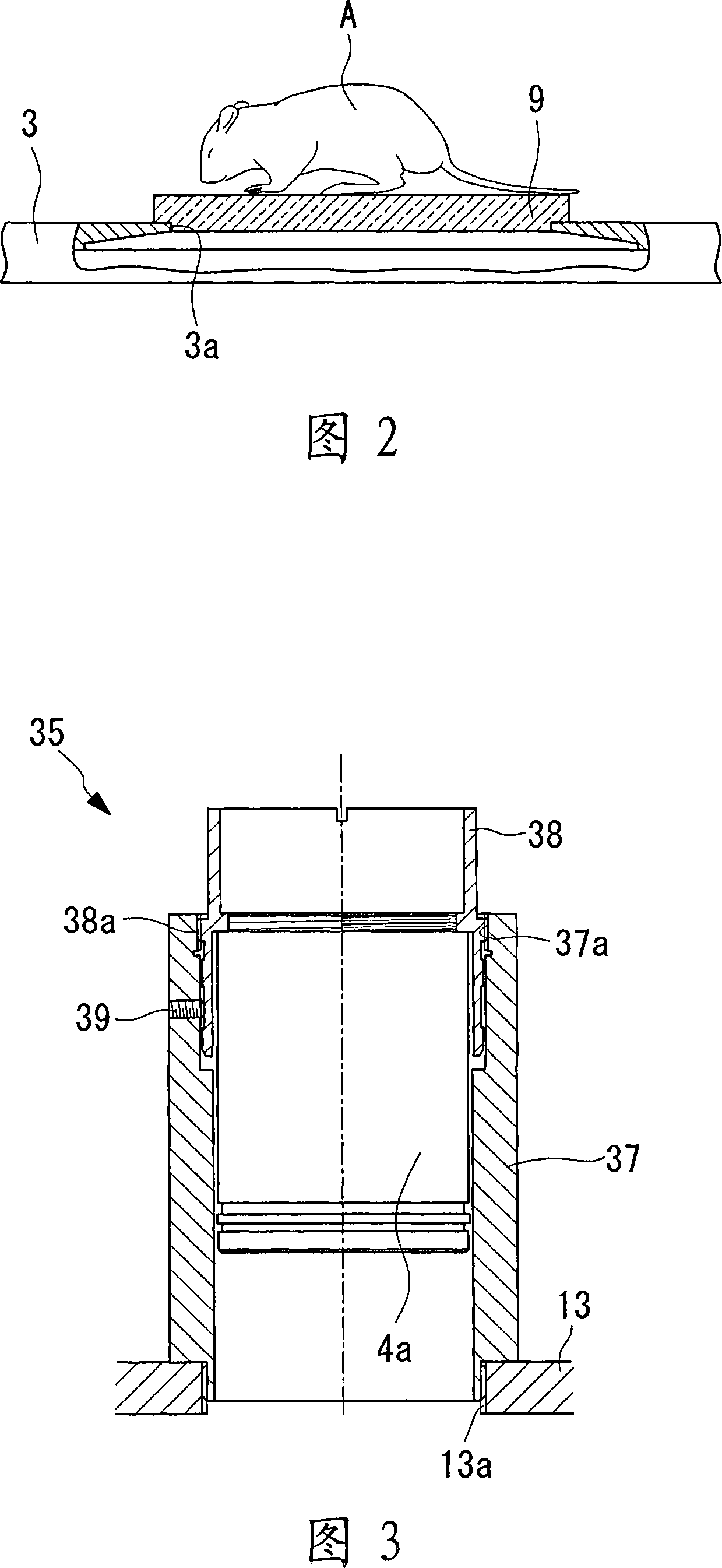

[0107] As shown in FIG. 1 , the microscope observation device 1 according to the present embodiment has: a light source 2 for generating light irradiated on experimental small animals such as mice or other samples A; a stage 3 on which the sample A is placed; The objective lens unit 4a~4d of the return light amplification of the object lens unit 4a~4d; The imaging lens unit 5a, 5b that makes the image on the sample A enlarged by the objective lens unit 4a~4d magnify, imaging; The image camera (camera unit)6.

[0108] The stage 3 is arranged on a base 7 arranged horizontally. The base 7 has: the 1st base 7a provided on the horizontal installation surface; and the 2nd base 7b horizontally arrange|positioned at intervals above the 1st base 7a. Between the 1st base 7a and the 2nd base 7b, the some spacer member 8 which...

no. 2 Embodiment approach

[0158] Next, a microscope observation device 60 according to a second embodiment of the present invention will be described with reference to FIG. 16 . In the description of the present embodiment, the same reference numerals are attached to the parts having the same configuration as those of the microscope observation apparatus 1 according to the first embodiment described above, and the description thereof will be omitted.

[0159] As shown in FIG. 16 , the microscope observation device 60 according to this embodiment differs from the microscope observation device 1 according to the first embodiment in that the turntable 13 , the arm 17 and the second turntable 62 are rotatably attached to a single column 61 . .

[0160] That is, as shown in FIG. 16 , the microscope observation device 60 according to this embodiment is equipped with a base 7 for fixing the stage 3 on which the sample A is mounted, and a support 61 extending vertically from the base 7 . A turntable 13 and a ...

no. 3 Embodiment approach

[0164] Next, a microscope observation device 70 according to a third embodiment of the present invention will be described below with reference to FIG. 17 .

[0165] In the description of the present embodiment, the same reference numerals are attached to the parts having the same configuration as those of the microscope observation apparatuses 1 and 60 according to the above-mentioned embodiments, and their descriptions are omitted.

[0166] The microscope observation device 70 according to the present embodiment is the same as the microscope observation device 60 according to the second embodiment in that it has a single support 61 fixed to the base 7 .

[0167] As shown in FIG. 17 , the microscope observation device 70 according to this embodiment has: a first lens group 71 composed of a low-power objective lens unit 4a and an imaging lens unit 5a; a high-power objective lens unit 4d, a zoom device 15, and an imaging lens unit 5a; The second lens group 72 formed by combinin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com