Special non-kinetic safety equipment of reactor

A safety facility and passive technology, applied in the field of nuclear reactors, can solve the problems of high construction and operation costs, many active parts, lack of passive characteristics, etc., and achieve the effect of improving inherent safety and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

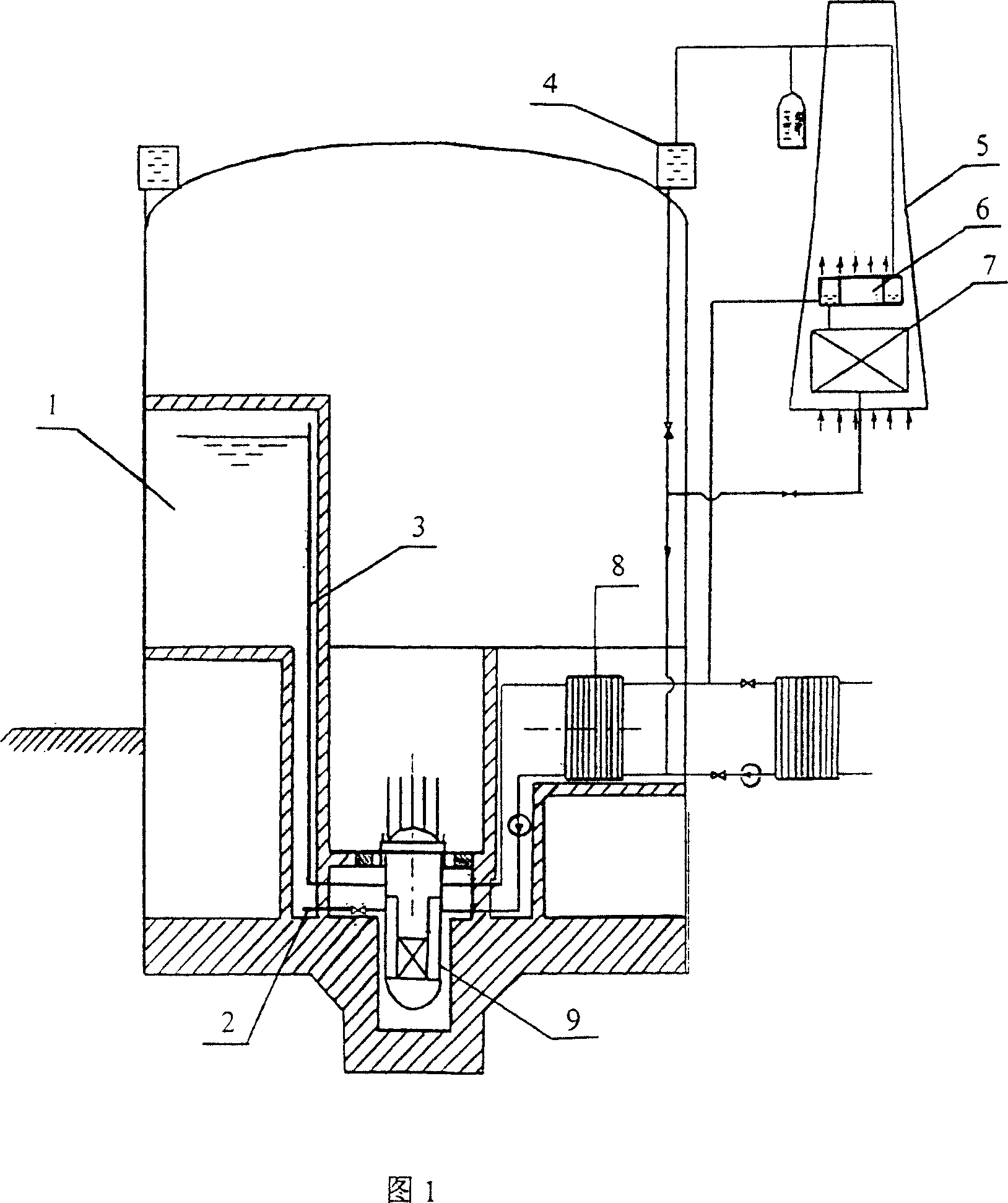

[0010] As shown in Figure 1, a large-capacity accumulator pool 1 that is 10 to 30 meters above the top of the reactor core is provided on one side of the reactor vessel 9, and a water injection pipe 2 that communicates with the mouth of the reactor is provided at the bottom of the accumulator pool 1. An ascending pipe 3 drawn out of the mouth passes through the pond and is higher than the water surface of the pond. During normal operation, the core pressure is maintained by the accumulator tank 1 and the water injection pipe 3 .

[0011] When the power is increased or the power fluctuates, the volume fluctuation of the temperature change is realized by the water injection pipe 3 .

[0012] In the event of a large break in the pipeline, the pressure of the reactor core drops rapidly. At this time, the accumulator pool 1 injects a large amount of water into the reactor core based on the level difference, so that the reactor core is always submerged. When the water between the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com