Dabber clamp for processing disc type gear

A technology of gears and mandrels, which is applied in the direction of manufacturing tools, metal processing equipment, gear teeth manufacturing devices, etc., can solve the problems of poor size adaptability, fluctuation of gear inner hole size and difficulty in ensuring product quality, etc., to eliminate processing errors and realize universal Sexuality and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

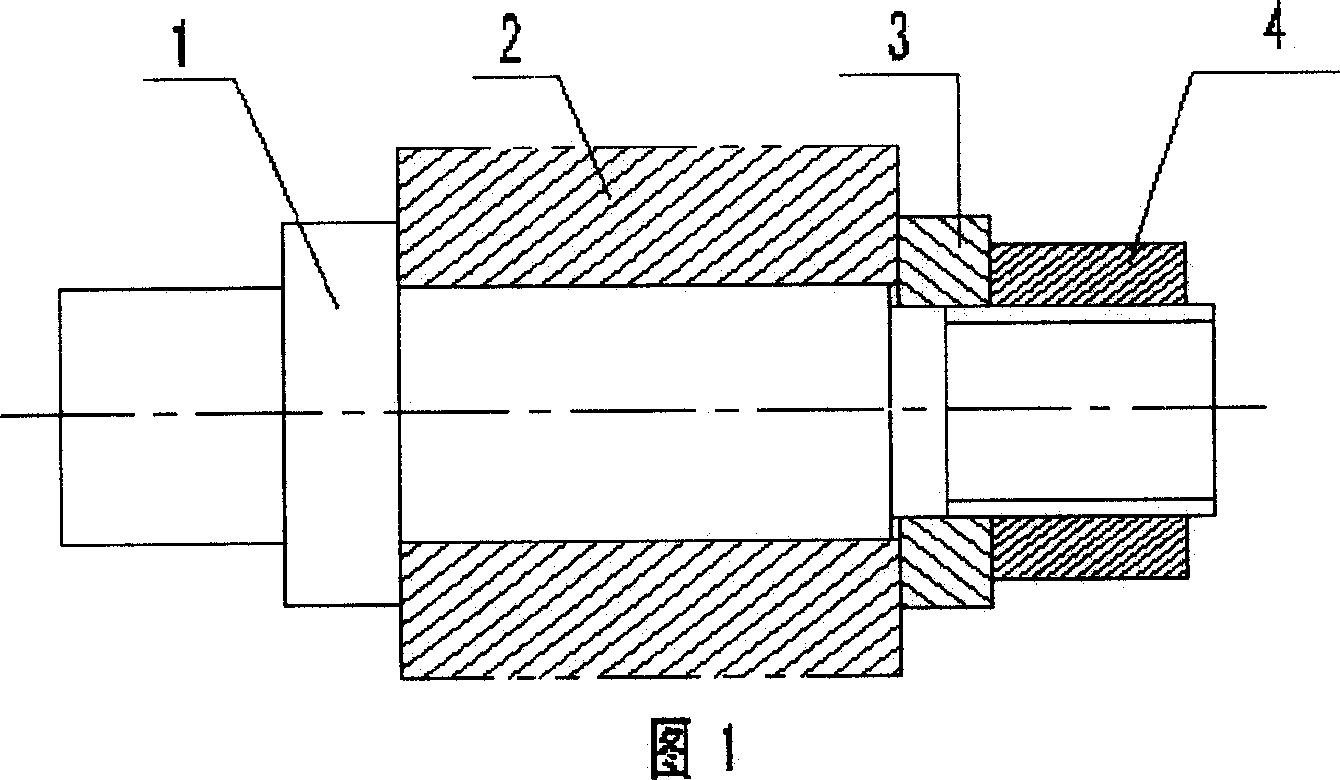

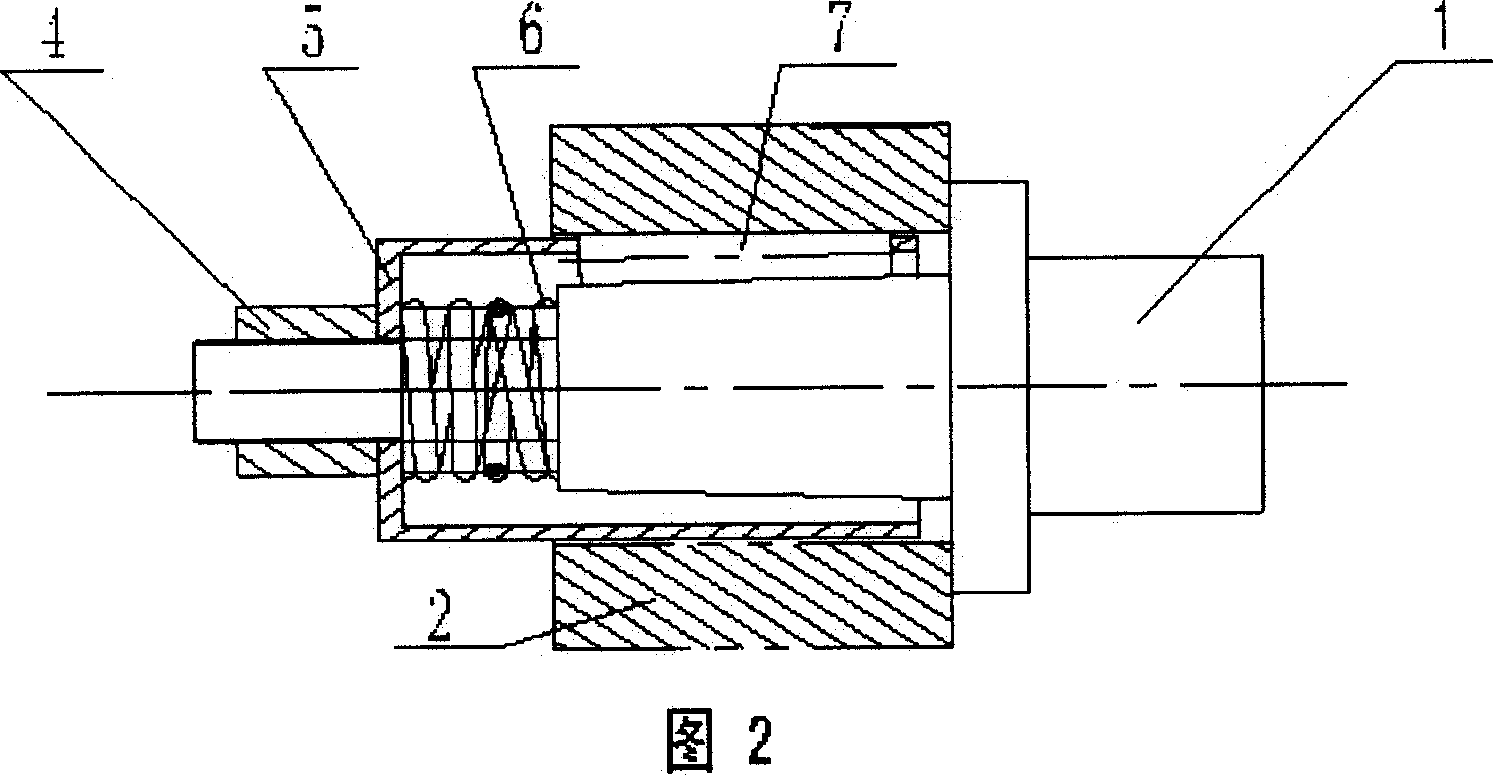

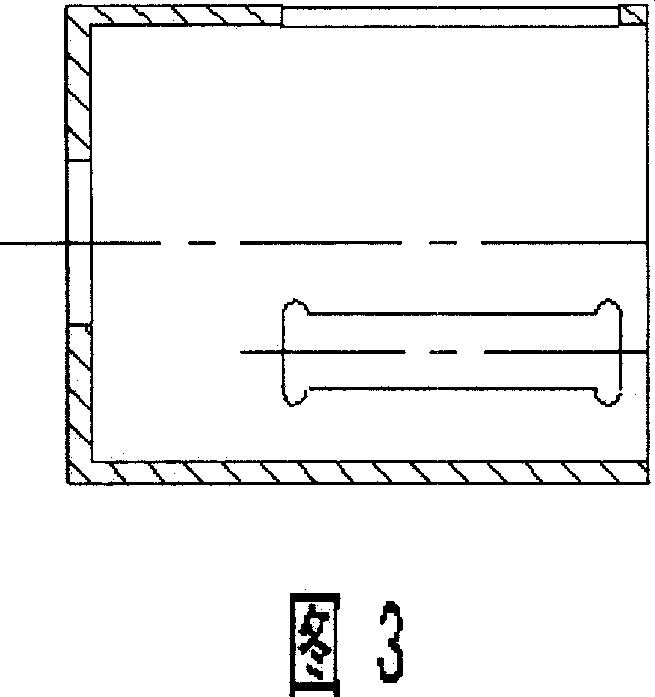

[0019] Embodiments of the present invention: the present invention is mainly composed of rigid mandrel 1, tapered needle roller 7, compression spring 6, needle roller cage 5, clamping nut 4 and other parts. Both the rigid mandrel 1 and the tapered needle roller 7 are manufactured with taper, the taper of the tapered needle roller is equal to 1 / 2 of the taper of the rigid mandrel, the number of tapered needle rollers is determined by the size of the inner hole of the processed gear part, generally 3 pieces Or more. The needle roller cage 4 has straight grooves on the circumference, the number of straight grooves is the same as that of the tapered needle rollers, and the axial direction of the tapered needle rollers in the grooves is matched with the straight grooves with a small gap. Assemble according to Figure 2, that is, the compression spring 6 and the needle roller cage 5 are respectively set on the rigid mandrel 1, the tapered needle roller 7 is placed in the groove of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com