Tower crane using giomagnetic sensor

A technology of geomagnetic sensors and tower cranes, which is applied in the direction of load hanging components, cranes, transportation and packaging, etc., can solve the problems of inconvenient installation of encoders, and achieve the effect of simple installation, high accuracy and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

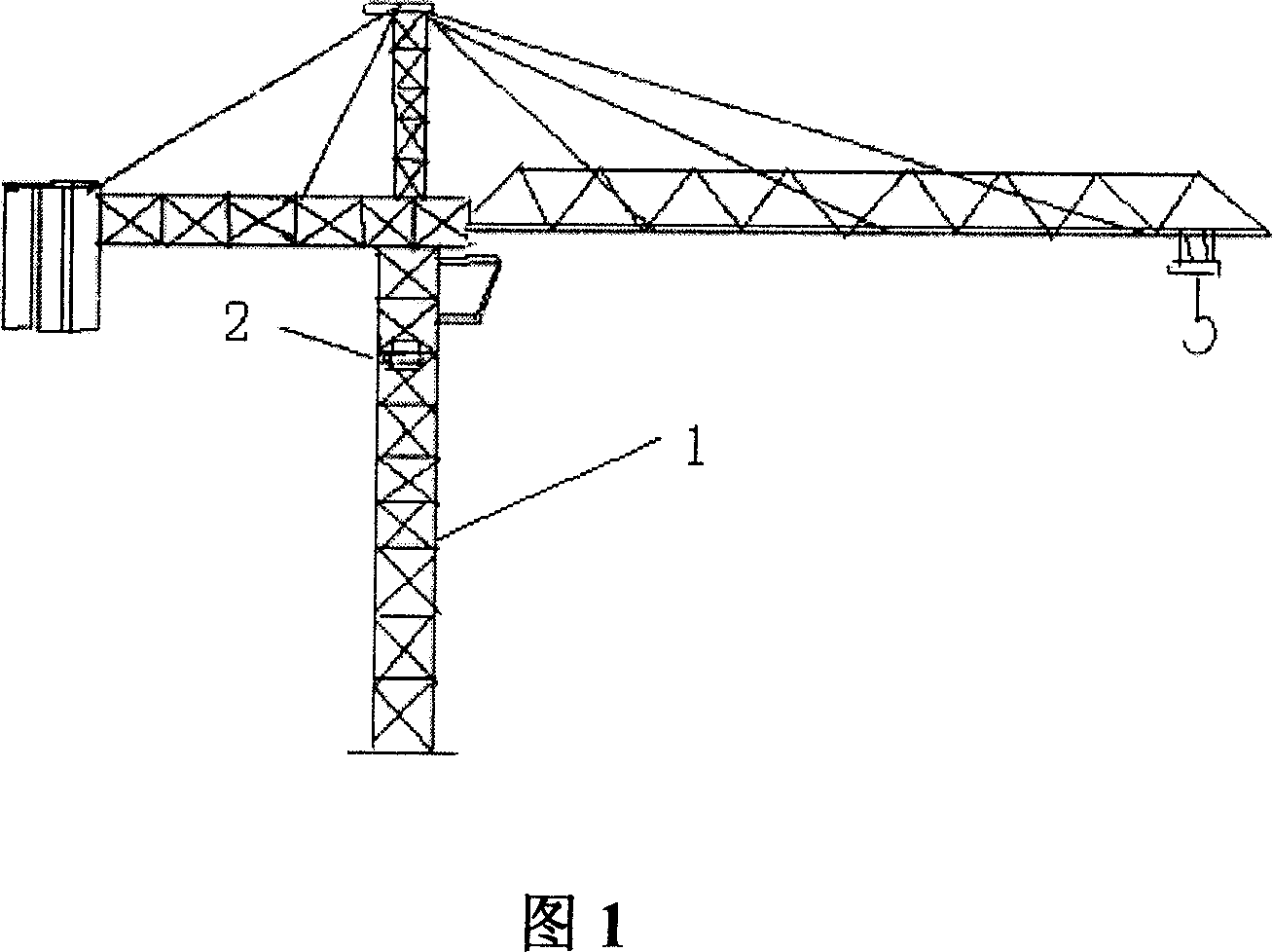

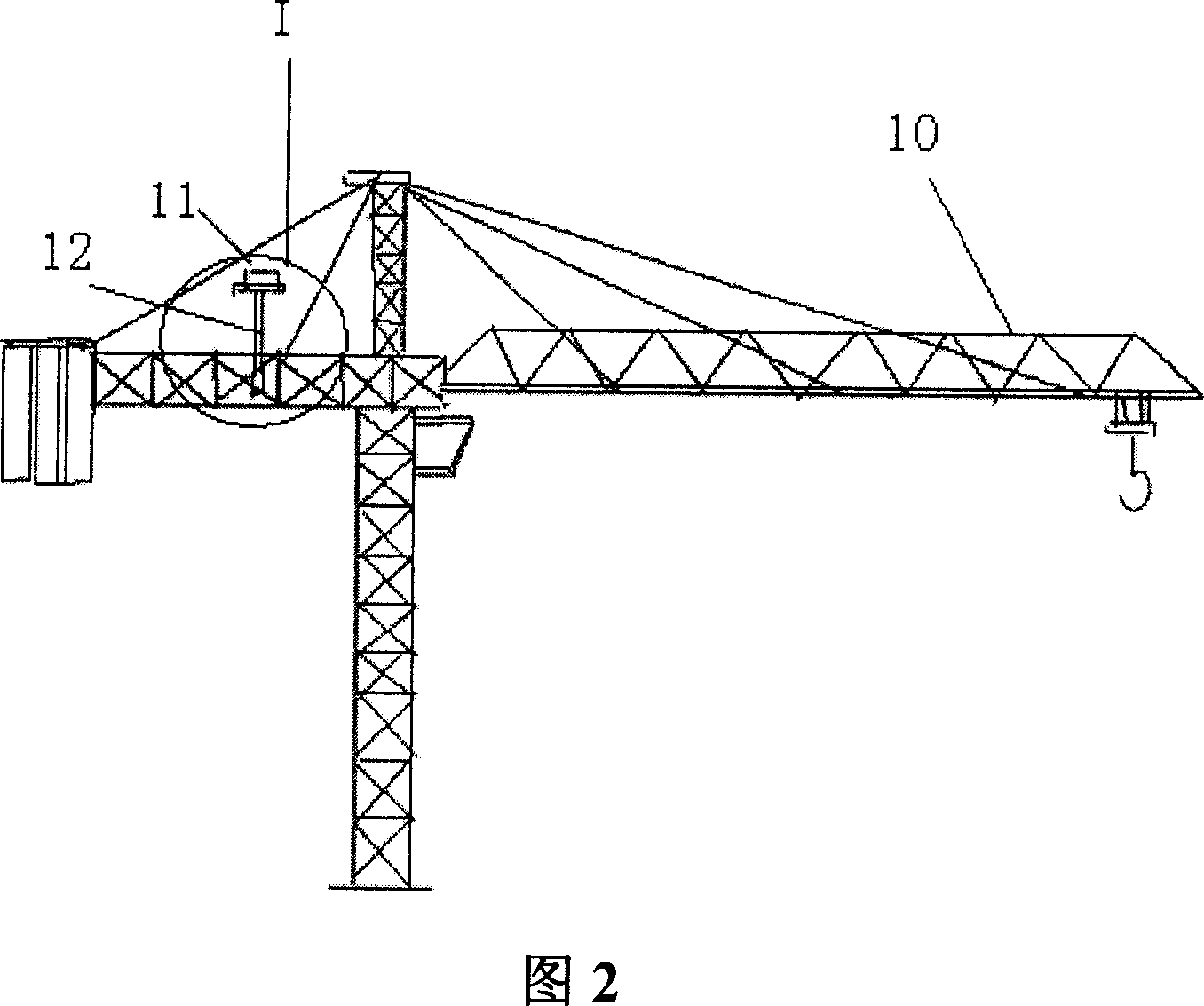

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

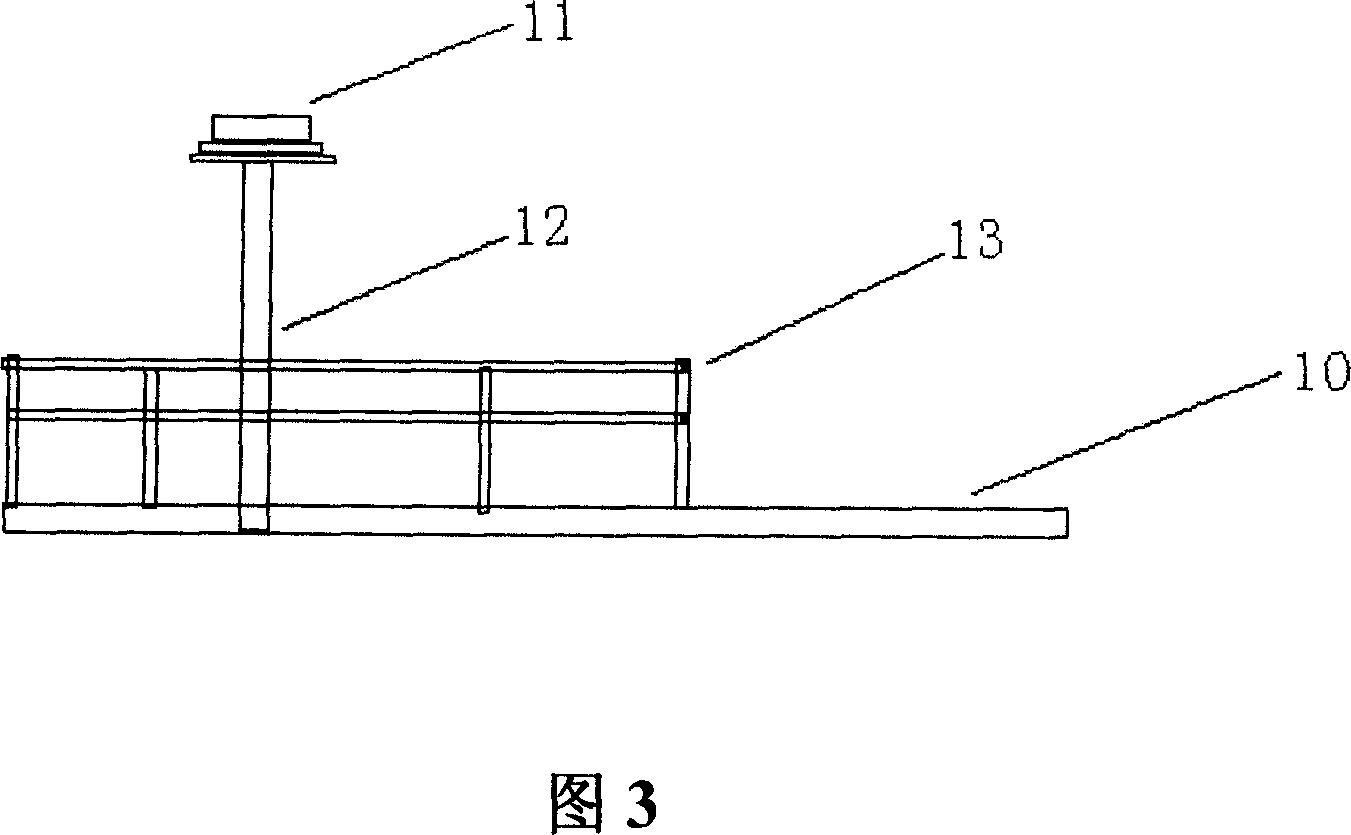

[0015] It can be seen from Fig. 2 that the present invention includes: the boom 10 of the tower crane; also includes: a geomagnetic sensor 11; the geomagnetic sensor 11 is fixedly placed on the balance arm of the boom 10;

[0016] Can also comprise a junction box that can play waterproof, put corrosion effect outside geomagnetic sensor 11;

[0017] A support 12 is fixed on the balance arm of the boom 10, and the geomagnetic sensor 11 is fixedly arranged on the upper end of the support 12;

[0018] The bracket 12 is fixed in the guardrail 13 of the balance arm.

[0019] The invention can measure the rotation angle of the tower crane and record the running conditions of the rotation angle, so that the operator of the tower crane can know the rotation angle value of the tower crane in time, and can lock the over-angle rotation operation of the tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com