Hydraulic drive apparatus of work machine

A technology for working machines and driving devices, applied in the direction of fluid pressure actuation devices, mechanical equipment, machines/engines, etc., can solve problems such as fuel cost reduction, reduction, fuel cost difference, etc. fee reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

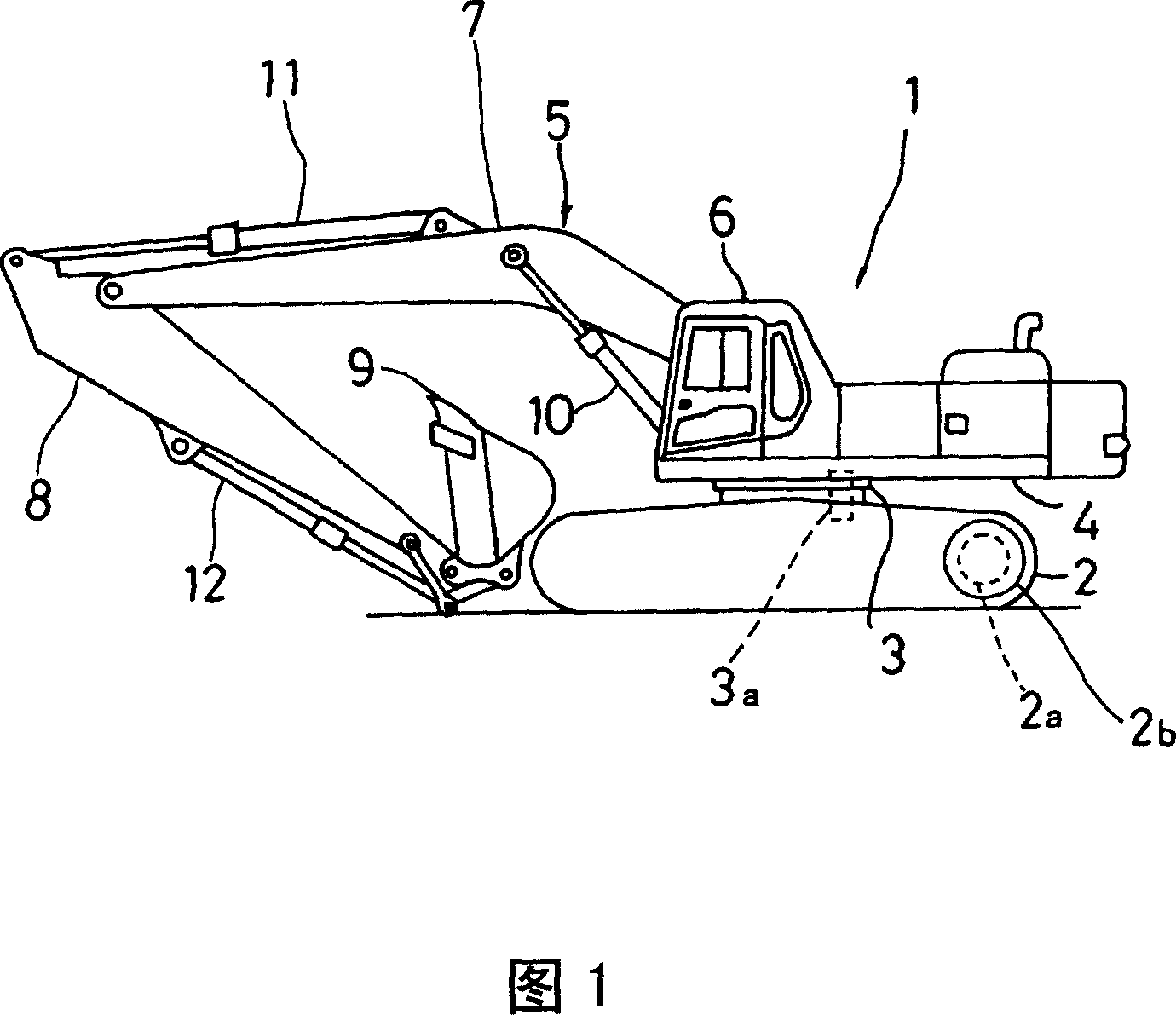

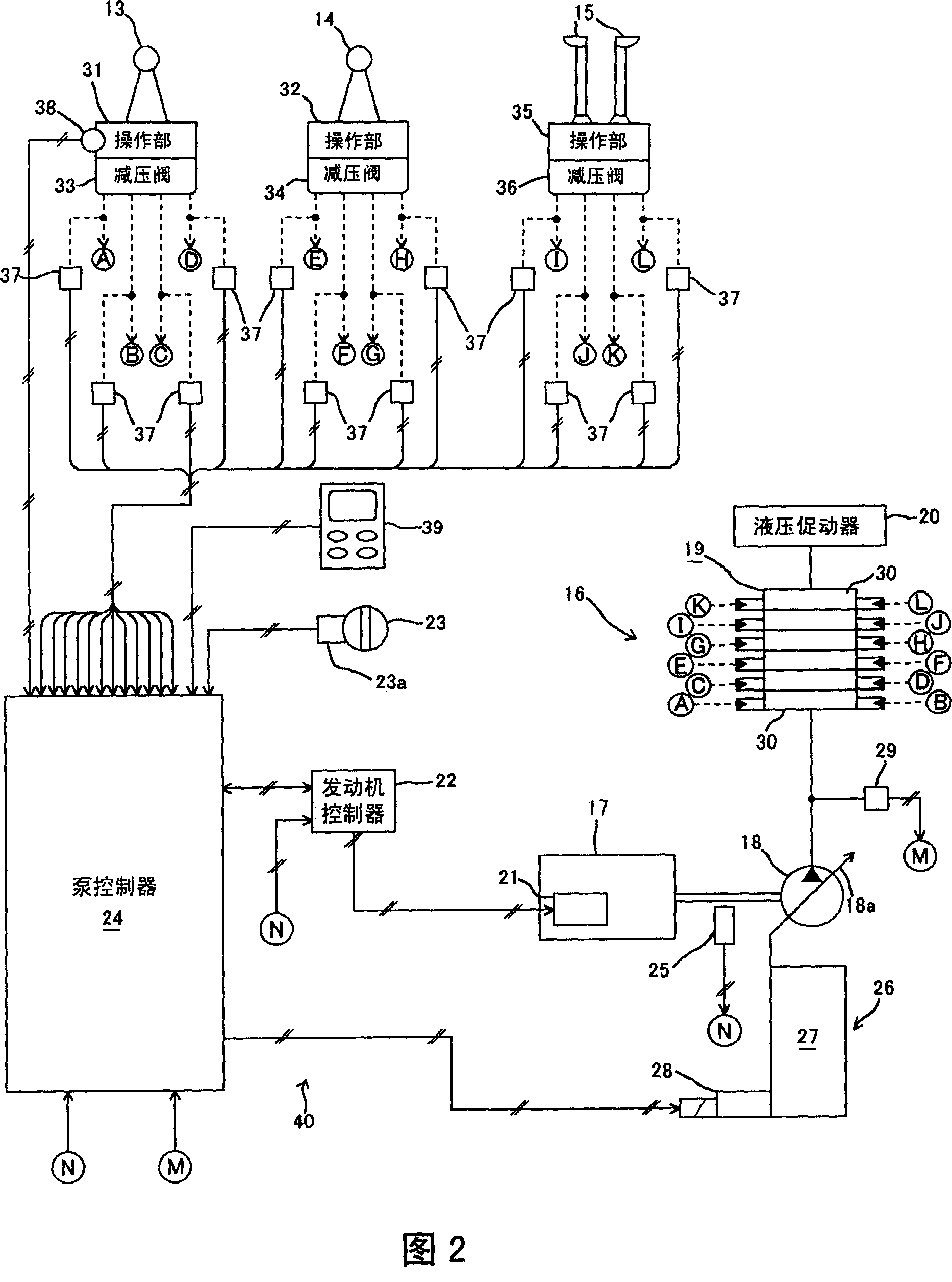

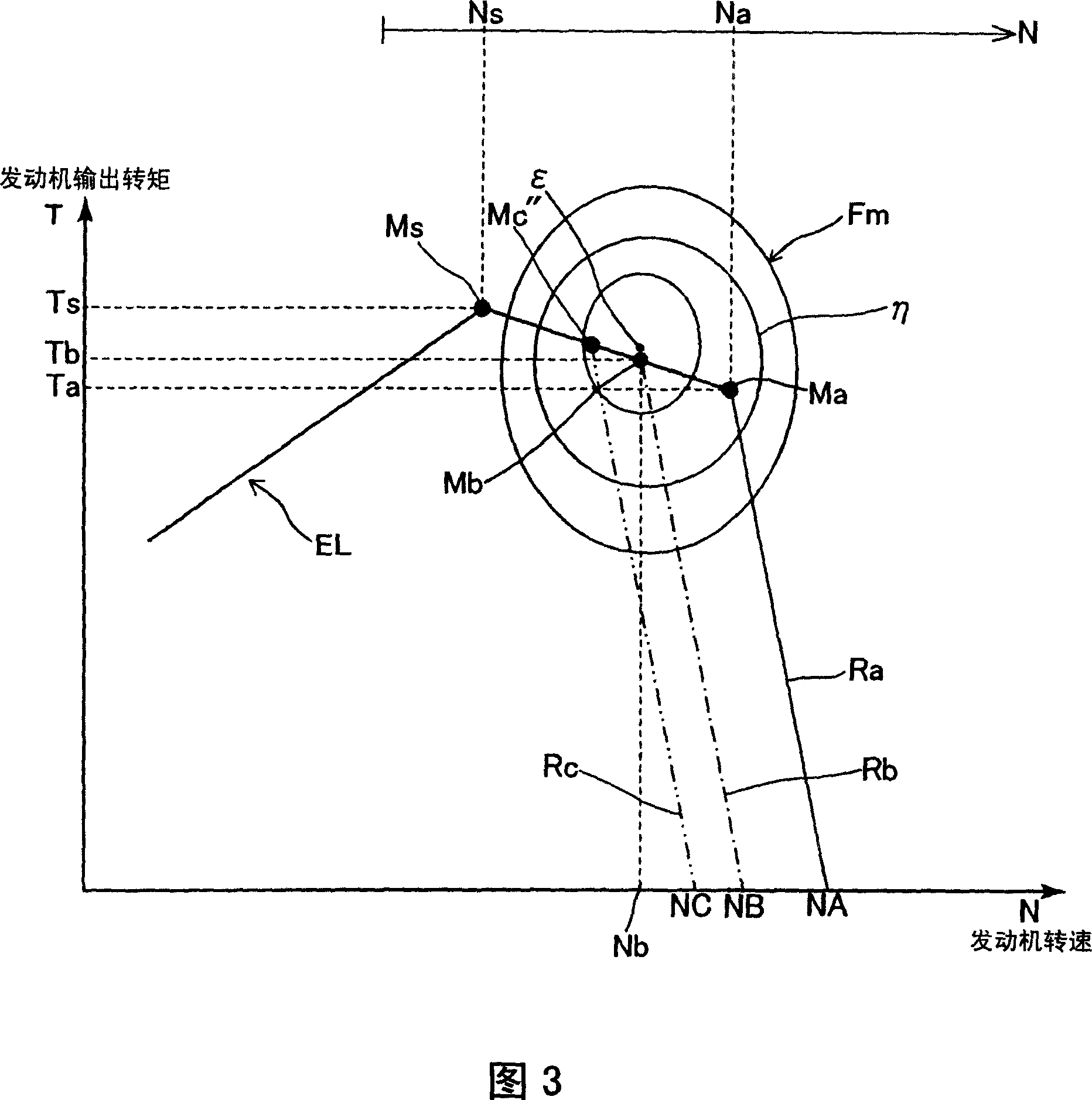

[0041] Next, specific embodiments of a hydraulic drive system for a working machine according to the present invention will be described with reference to the drawings. In addition, this embodiment is an example in which the present invention is applied to a hydraulic excavator as a work machine.

[0042] FIG. 1 shows a side view of a hydraulic excavator according to an embodiment of the present invention. In addition, FIG. 2 shows an overall schematic system configuration diagram of a hydraulic drive device according to this embodiment, FIG. 3 shows an output torque characteristic diagram of an engine according to this embodiment, and FIG. 4 shows the functions of an engine-hydraulic pump control device according to this embodiment. block diagram.

[0043] A hydraulic excavator 1 according to the present embodiment is provided with, as shown in FIG. 1 , an undercarriage 2 provided with a traveling device 2b driven by a traveling hydraulic motor 2a, and a swivel device 3 driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com