Plug-in connection provided with an angle-locking device

A technology of plug connectors and locking devices, applied in the direction of couplings, mechanical equipment, etc., can solve problems such as cuts and accidents, and achieve the effect of simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

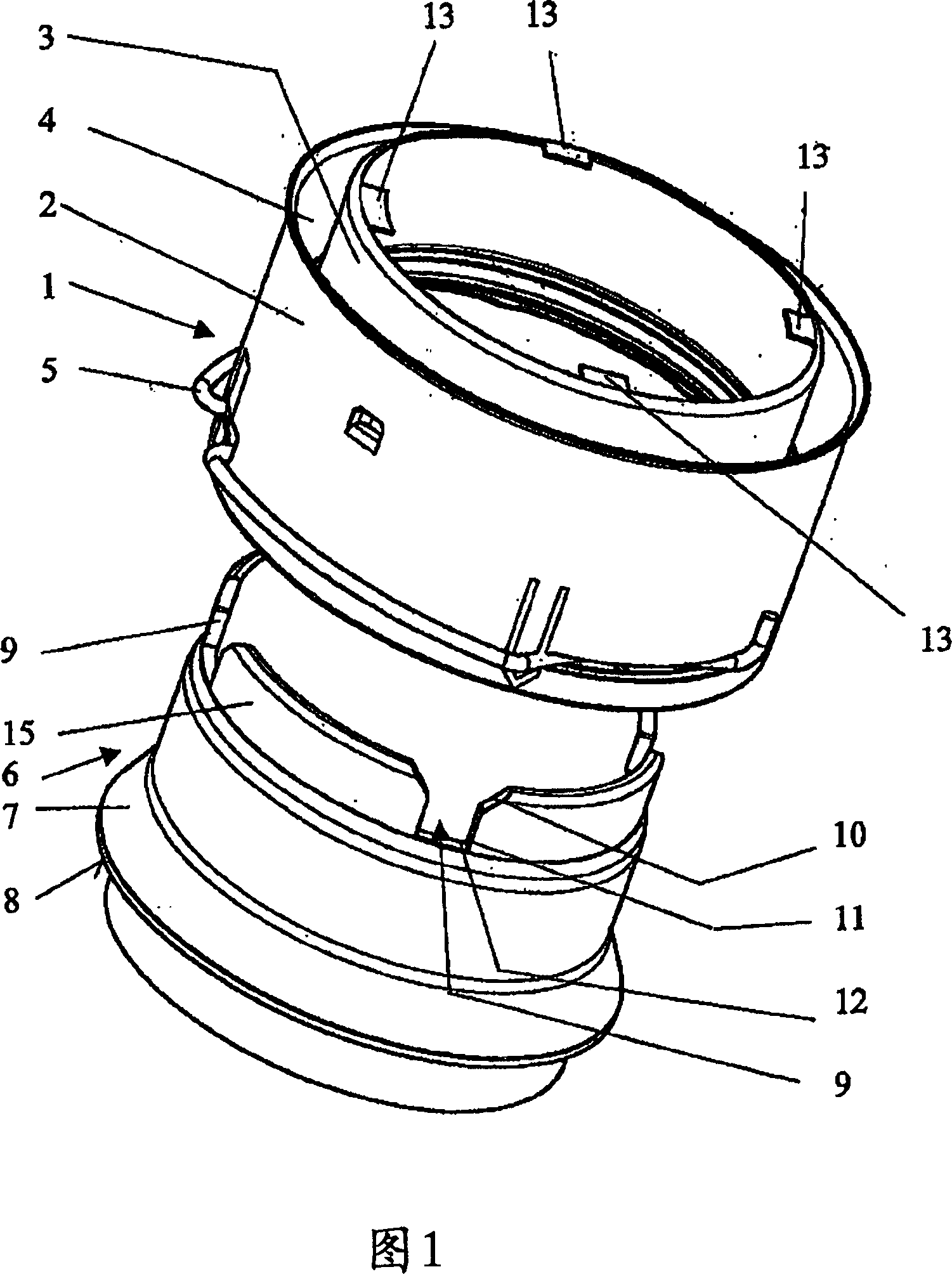

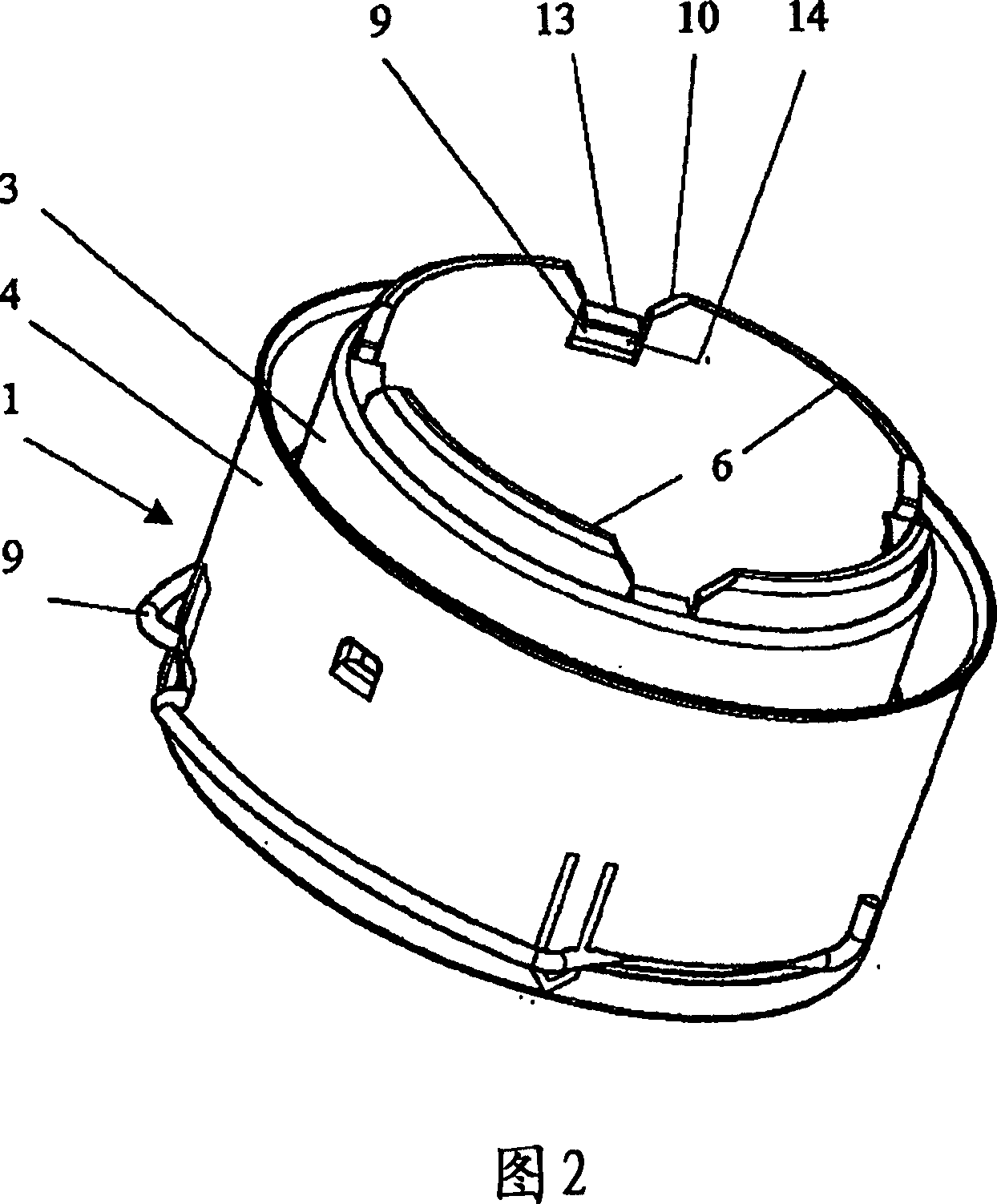

[0026] As shown in Fig. 1, a plug 1 includes an outer sleeve 2 and an inner sleeve 3 integrally connected with it. However, the present invention is not limited to this. The plug can also be arranged in any other embodiment, in particular the outer sleeve 2 can be completely eliminated.

[0027] In the intermediate space between the outer sleeve 2 and the inner sleeve 3, an annularly surrounding receiving space 4 is provided, in which a hose end is inserted in the axial direction, and it is tightly fixed there.

[0028] However, the invention can also provide that the plug piece is formed integrally with the hose material connected to it.

[0029] In order to establish a snap connection, the plug 1 is provided with a snap spring 5 in the front area, which protrudes into the inner diameter of the plug 1 with multiple bends.

[0030] A pipe joint 6 can be inserted into the inner space of the plug 1, and a plurality of guide openings 9 distributed along the circumference are formed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com